The term big data may at first appear incongruous to animal agriculture. However, by capturing, analysing, reporting and sharing of through-production chain data with decision makers, organizations are better equipped to make informed decisions. Pivotal to this process is the type of data, its relevance, accuracy, and integrity.

The importance of capturing relevant, accurate data that is reported in a meaningful time and space cannot be underestimated. However, significant challenges exist with big data for poultry production, not least with the very basics of capturing data, storage, security, analysing as well as effecting meaningful change based on the data.

Introduction

Agricultural industries are on the cusp of a digital revolution. Rising demand for higher yields, combined with constraints on finite resources such as land and water, has placed increased pressure on the input side of agriculture. The increased demand on agricultural outputs from an increasing global population and socioeconomic growth has intensified the pressure on the agricultural sector to produce more with less. Current projections for population growth estimate that the world population will reach 9 billion people by 2050 and, in order to feed this number of people, overall food production will need to increase by approximately 70% between 2007 and 2050 (FAO, 2009).

Traditionally, to meet this increase in demand, the agricultural sector would more often than not apply the ‘bigger is better’ principle and expand production by clearing more land or increasing the intensity of production. However, this strategy is becoming increasingly difficult from an environmental perspective and is often in conflict with spreading population centres that prioritize arable land for urban development. Adding to this dilemma is the estimate from the Food and Agriculture Organisation that between 20-40 % of annual global crop production is lost to pests and diseases.

To counter this inefficiency, a simplistic approach would be to apply more fertilizer and/or insecticides yet paradoxically (from a production volume view) consumers and governments are demanding fewer chemicals be applied. This somewhat parallels the current direction of poultry production. Traditional technologies such as antibiotic growth promoters are facing increased scrutiny and pressure globally to be reduced or removed entirely.

While poultry production can expand by adding more sheds (within limits) to meet rising demand, the volume of poultry products that can be produced from each unit on a square metre basis has also faced downward pressure on account of reduced stocking densities. These scenarios have the potential to impair the growth in production volume and lead to shortages in food production at the very moment when more is required. It is also evident that the poultry industry cannot rely on past expansion strategies alone to meet this increased demand. To help meet this challenge, a proposed key to facilitate increased food production in a time of tightening inputs lies with Agriculture 4.0 and big data technologies.

a) Smart Farming

The development and application of smart farming began in the late 1990’s with the introduction of precision farming whereby technology was applied to the production of agricultural commodities for the first time. However, precision farming focussed largely on farm machinery used in the production of crops with assistive technologies such as global positioning systems to reduce overlap when turning at the ends of the field and therefore improving sowing, harvesting and fuel efficiencies. The next iteration of smart farming is termed Agriculture 4.0 which is a continuation of precision farming and is hailed as the new era in modern agriculture. The foundations of Agriculture 4.0 rely on the increased use of mechanized processes (from paddock to plate) that are supported by the Internet of Things (IoT), big data, wireless/mobile communications and cloud computing. Agriculture 4.0 monitors each step of the food production chain from the first input to the last output.

The Internet of Things and big data are terms used to describe technologies that are embedded in everyday objects and are interconnected via the internet and ultimately produce large data sets. For poultry production, this will result in more sensors and data inputs at each step of the value-chain. However, a consequence of this will be that the data sets produced will be so big and vast that traditional data processing software is insufficient to handle these data sets. Importantly, big data also refers to the use of predictive analysis that moves beyond the basics of reporting data and analyses data for correlations and patterns from which businesses may then extract value.

b) Data acquisition

Data acquisition is perhaps one of the easiest components of big data for poultry production. Currently, there are numerous sources of data acquisition ranging from the production statistics on the breeder farm right through the value chain to consumer preferences at the retail level. However, not all of these data are collated and able to be analysed in depth, with some sources of data analysed (at best) or sitting unanalyzed in isolation (at worst). Yet to achieve improved efficiency, it is important that all of these data are captured and analysed in a holistic manner.

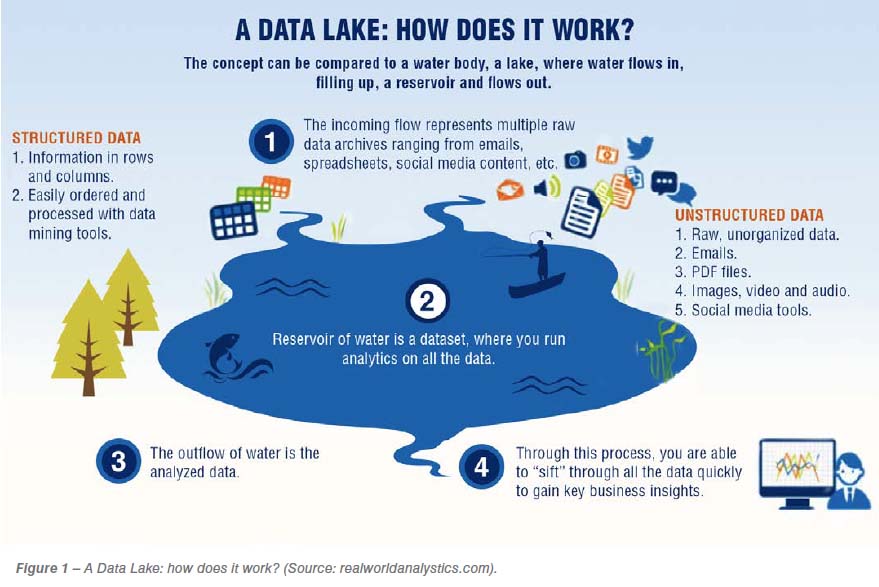

It is often described that organizations build a data lake which is akin to constructing a man-made water reservoir (Figure 1). First the dam is created, is then filled with water (data) and once the lake begins to fill, the water (data) is then used for other value adding purposes. A data lake provides a platform for rapid data accumulation and, potentially, its application. While this represents a significant advancement, the transformation analysis and application of the data is more complex and represents a major challenge to organizations. After a data lake is created, the propensity to measure and capture data increases significantly and may lead to an overload of data. Measuring something for the sake of measuring it should be avoided for “sometimes what counts, can’t be counted and what can be counted, doesn’t count (Cameron, 1963). For each new data stream, an analysis of the proposed benefits should be applied prior to its creation, and a review after it is active, to evaluate the value of the data. The value of data streams may be under or overestimated and it is the analysis and interpretation of these data where expertise is required in order to maximise the value and application of big data.

c) When good info goes bad: the cost of data errors

Efficient poultry production is reliant on accurate data. Performance targets currently exist for each step of the production chain from the breeder farms, through to the hatchery, for on farm growth, feed efficiency as well as processing. For most integrators, these values may be summarized as cents/kg of poultry meat products or cents/dozen eggs for table egg producers. If we accept the average benchmark of a 1% error rate in manual data entry and multiply this by the instances of manual data entry, the consequences of these missteps can be profound. The human ability to catch or avoid errors is inherently flawed and if data needs to be entered multiple times, this only exacerbates the problem. A common business concept is the 1-10-100 rule which illustrates the importance of correcting data entry mistakes at the source. According to the 1-10-100 rule, it costs $1 to verify the accuracy of the data at the point of entry, $10 to correct or clean up the data in batch form, and $100 (or more) per record if no corrective action is performed. While the absolute value of individual and cumulative data errors to companies may differ, the principle remains the same. Reliable and timely data are essential. Using the underlying technologies of Agriculture 4.0 to capture and report this data automatically using connected sensors and online platforms will lead to increased accuracy and facilitate timely decision making.

The following categories of data described in this paper represent some suggested data streams for big data in poultry production with a focus on streams that have the potential to be transformational.

End of the first part

Read the second part here

References are available on request

Source: From the Proceedings of the 2019 Australian Poultry Science Symposium