The highly acclaimed Eindhoven University of Technology (TU/e) in the Netherlands has set up a new Artificial Intelligence (AI) lab, together with four industrial partners including Marel. This lab aims at improving decision-making in manufacturing and maintenance using artificial intelligence.

With the establishment last year of EAISI (Eindhoven Artificial Intelligence Systems Institute) and the growing interest in using AI to accomplish sophisticated tasks, TU/e’s logical next step was to set up an AI-enabled Manufacturing and Maintenance (AIMM) lab. The lab will be part of the Dutch network of ICAI (Innovation Center for Artificial intelligence), aimed at technology and talent development between knowledge institutes, industry and government in the area of AI.

Innovation and talent

The AIMM lab aims to promote research together with the high-tech industry and collaborates with four industrial partners Marel, Nexperia, KMWE and Lely. This new lab embodies the ambition of all participants to play a leading role in the further development of AI in the Netherlands.

The cooperation between the TU/e and the industrial partners will have benefits for innovation as well as the development of talent. Students and Ph.D. researchers will perform joint research, also at the Marel site in Boxmeer. TU/e has been active in the field of AI for decades, while Marel also has a thorough knowledge of AI, which gives the new laboratory an excellent starting position.

High expectations

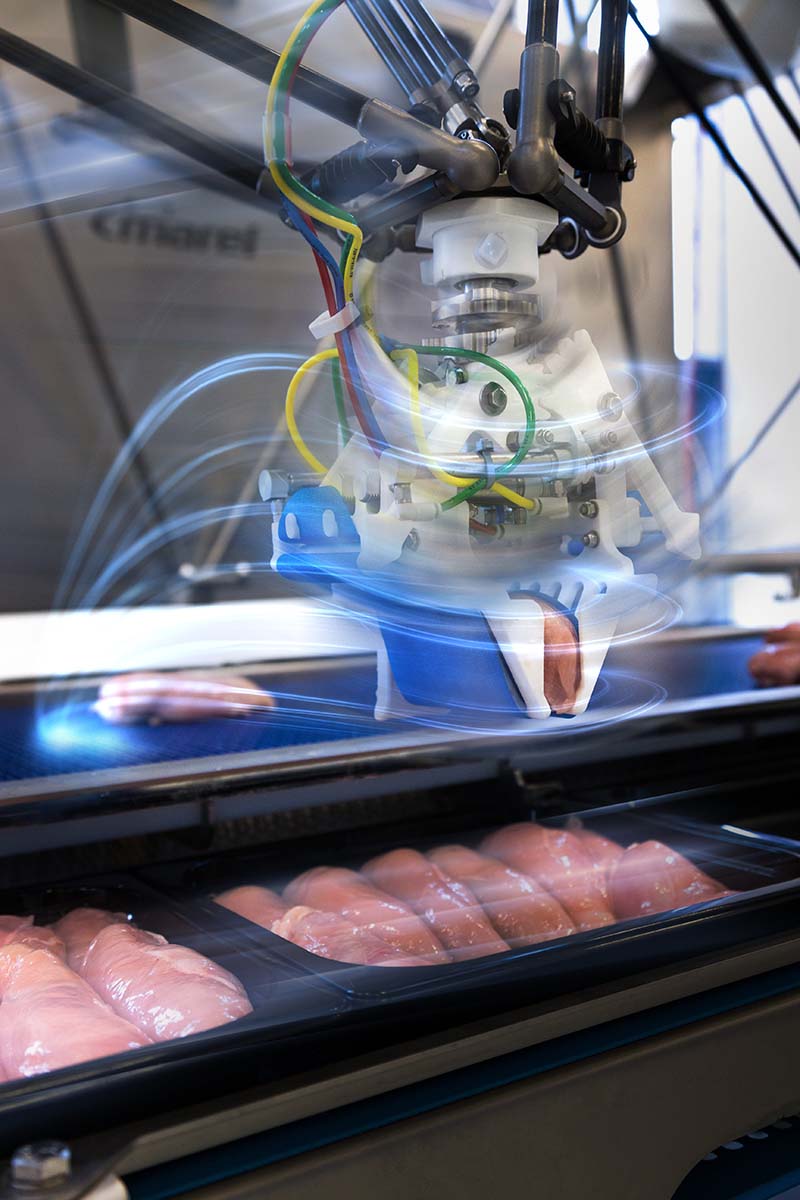

By taking part in this AIMM lab, Marel expects to be able to respond to the rapidly increasing demand for education, engineers and expertise in the field of AI. “Backed by our experience in system engineering and our close relationship with TU/e, we have high expectations of this collaboration. I can think of various practical applications of AI in our food processing systems,” says Liliane de Nie, Innovation Director at Marel. “The lab’s research will allow us to make considerable progress on high-tech areas which are crucial to our industry, such as robotics, guaranteed machine performance, and man-machine interaction. When it comes to servicing our customers, adding AI to our programs will help us in optimizing the corrective, preventive and predictive maintenance strategies. We’ll be able to utilize our maintenance concept to its full potential in the market.”

Decision-making

Jeroen van Oers, Manufacturing Director at Marel adds, “In our manufacturing environment, we have to deal with complex decision-making processes. Just one example: customer demand for our parts is an almost unpredictable, constantly changing mix. So, we have to decide on the best way of sourcing this demand. Also, we need the flexibility to keep our supply base performances stable under varying circumstances. To that effect, we have to develop our supply base and utilize our machines to the max. Our participation in the AIMM lab will allow us to call in AI and help us solve these kinds of issues.”

Liliane de Nie concludes, “This is another excellent collaboration between Marel and TU/e and we’re already excited about the joint AI research.”