Clean and fresh drinking water is essential for bird health and performance. Even when the incoming water is clean, a biofilm may rapidly form at the inner lining of a drinking water system. This biofilm reduces the water flow, clogs drinking nipples, and provides an ideal hiding place for pathogens.

Biofilm is an invisible threat

The build-up of a biofilm typically starts with the attachment of a single microorganism cell in suspension onto a surface, for example the inner surface of a drinking water line. This microorganism starts to multiply and secretes extracellular matrix components to build a protective environment. So the biofilm inside a line is not just a slimy layer, but actually a well-structured and highly organized microbial community. This process of biofilm formation is further accelerated by the relatively high temperatures in a broiler house, and stimulated by the low water flow volumes at the start of a round.

Intra Hydrocare effectively removes biofilm

Traditional disinfectants, like chlorine, may disinfect the water, but form harmful residues and/or negatively affect the taste of the water. Intra Hydrocare is a silver-stabilized hydrogen peroxide solution that disinfects the water and also physically removes the biofilm from the inner lining, without residues and taste changes. Due to its unparalleled stability, Intra Hydrocare remains active from the beginning of the water line until the last nipple. Its addition to the drinking water guarantees that the water will remain free of microorganisms and no biofilm will build up in the water system. The functionality of Intra Hydrocare has proven itself around the globe in the most varying practical conditions, the study described in this article clearly visualizes its functionality under experimental test conditions.

Biofilm generator to study biofilm formation and removal

Intracare has developed a biofilm generator as a model to study the natural growth and subsequent removal of biofilm with Intra Hydrocare in an experimental set-up. Plastic tubes representing the drinking water lines were filled with contaminated water and animal drinking behavior was mimicked by a daily flow/no-flow schedule. Water quality was determined by measuring the amount of adenosine triphosphate (ATP) as a marker for micro-organisms using the Intra Clean Quick Scan in Relative Light Units (RLU). Removable plastic inserts were positioned inside the tubes to assess the number of bacteria in the biofilm.

When the growing biofilm was clearly visible by eye and water ATP measurements started to stabilize, the continuous addition of an extremely low ppm level of Intra Hydrocare was started to investigate its effect on the biofilm.

Visible growth of biofilm and its fast removal with Intra Hydrocare

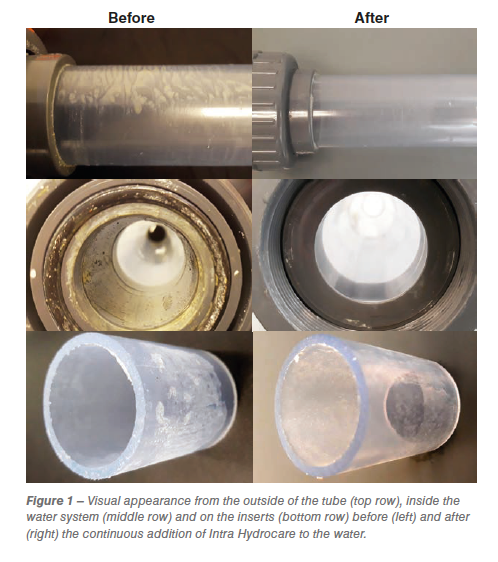

From the start of the experiment, a gradual formation of a biofilm was noticed by eye, resulting in a clearly visible greasy layer in the inner lining of the tubing and inserts (Figure 1). This visible biofilm completely disappeared from all surfaces after the continuous addition of Intra Hydrocare was started.

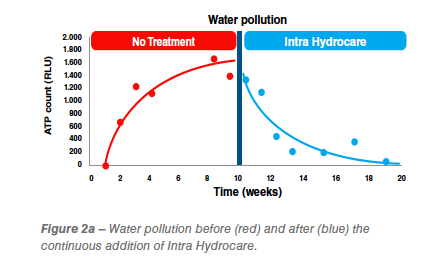

During the biofilm growing period, the water ATP count rapidly increased up to 1,662 RLU, indicating severely polluted water (Figure 2a). After the continuous low maintenance addition of Intra Hydrocare, the RLU count rapidly decreased within a short timeframe and remained low, as the measurement in week 19 shows with an RLU value of 66.

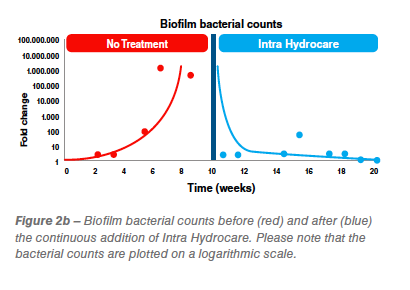

The ATP measurements are in line with the bacterial counts from the inserts, which rapidly increased within 6 weeks (Figure 2b) to an almost two million-fold (1.9 x 106) increase. The subsequent continuous addition of Intra Hydrocare quickly resulted in a two million-fold (log 6) decrease, demonstrating the fast and effective removal of microbiological contamination from the surface of the inserts and inner lining of the tubes.

Practical use of Intra Hydrocare in broiler houses

The biofilm generator enabled us to visualize the rapid growth of a biofilm inside a drinking water system and clearly demonstrated the fast and effective removal of this biofilm already with the continuous addition of low maintenance ppm levels of Intra Hydrocare. The RLU measurements in this laboratory model indicate that with these extremely low levels it may take up to two weeks before the entire system is cleaned. In order to guarantee direct results, it is in broiler houses allowed to use a higher maintenance dosage up to 250 ppm. Especially when taking into account that in practice the water system will also be used for the addition of feed supplements or medication to the animals, and during these days it is not advised to dose Intra Hydrocare. Please note that for a quick and effective cleaning and disinfection of the drinking water system, the lines of an empty house should always be cleaned with 1-3% Intra Hydrocare to guarantee a clean system at start of a new round. A low maintenance dosage during the round ensures that the water system remains clean.