Raising turkeys is equal parts science and art. It involves precise measurement of various factors throughout the life of the flock. It also requires that farmers be able to look and listen to their flocks and sense when something is just…“not right”. On the scientific side, decades of experience show that adjusting the small details and investing time and effort at the beginning of life can have the biggest impact on total performance. What are these small details and how can you address them in your operation?

Getting off to a good start

Final flock performance can be influenced early in the production cycle. It is important to get poults off to a good start, which includes maintaining the right environmental conditions, optimal health and nutrition. Whether you have the most innovative and up-to-date equipment or have an older facility, a good start will set your flock up for success and requires investing time and attention into this key period. Small details during this time, that can make a world of difference, include temperature, gas and feed management.

Temperature management

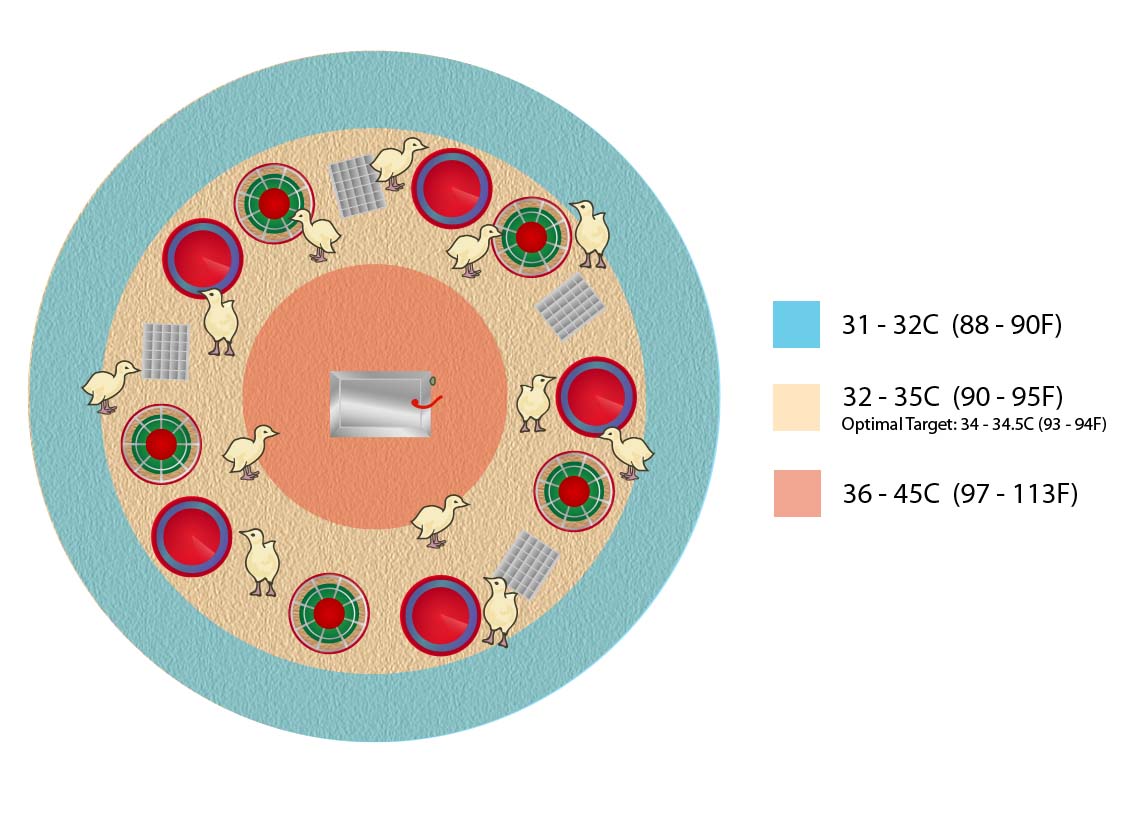

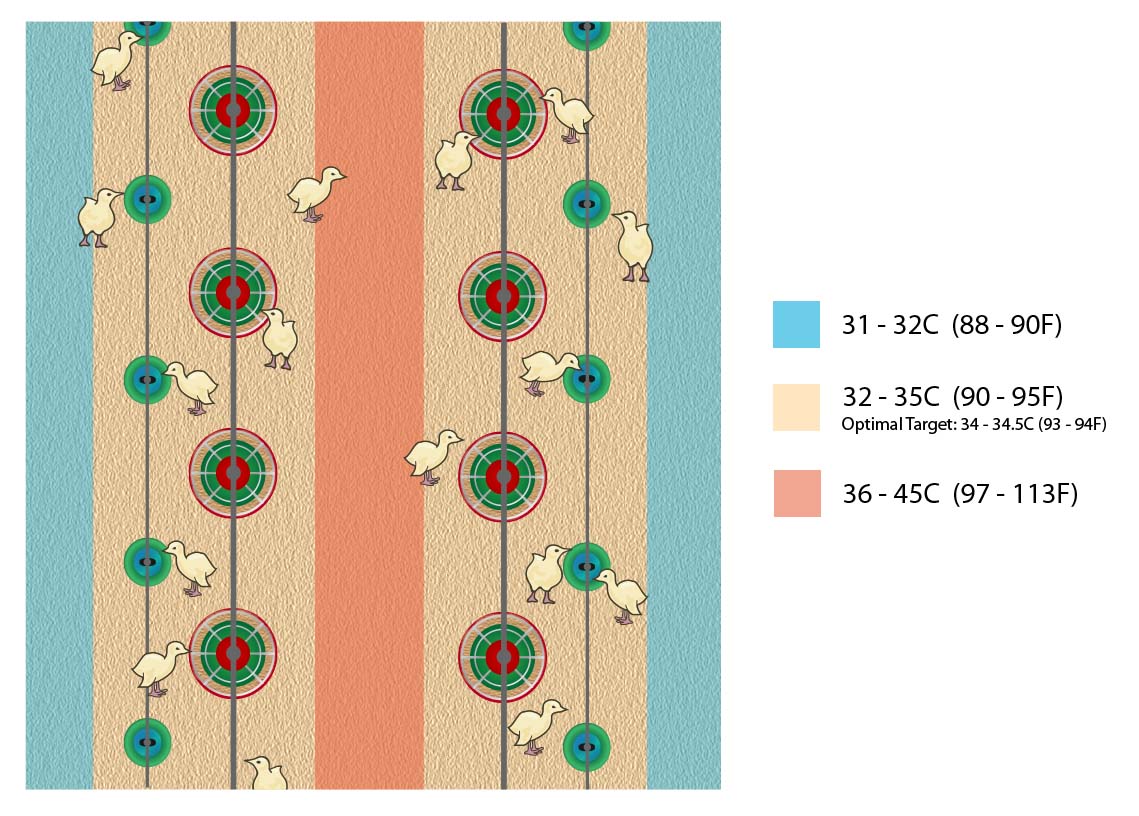

Before poults arrive, Hybrid recommends pre-heating the barn for 24-48 hours before placement or up to 72 hours during extreme cold. Optimal floor temperatures should be 32 °C-35 °C (90 °F-95 °F) across the feed and water space. The small detail that can make a huge impact is where you measure this temperature. If you measure temperature at standing height you are not gaining a very good indication of what the poults will feel. Hybrid recommends testing temperature during brooding at bird-height or to test litter temperature to gain a better understanding.

When checking litter temperature, you should measure not only the surface temperature, but also the lower layer to evaluate if your pre-heating efforts will pay off when the poults arrive. You can check that the heat is built into the litter by measuring the top of the litter surface then push away about 2 cm of the litter and measure the lower layer. There should only be a 0.5 °C (1 °F) difference between the top and lower layer. This is important as when the birds arrive the litter will be pushed around, and you want to ensure consistent temperature to keep the poults comfortable.

Since poults are not able to regulate their internal temperature during the first days of life, it is very important to ensure their environment is warm enough to provide comfort for them to move around and find feed and water. As mentioned above, the brooding environment should have an even distribution of floor temperatures ranging from 90-95 °F (32-35 °C), with an optimal target of 93-94 °F (34-34.5 °C) across the feed and water space. The images below showcase applicable ranges of temperature whether using whole room or ring brooding set ups.

Gases

Another check to perform, before and after the birds arrive, is to test the levels of carbon dioxide and carbon monoxide. Carbon dioxide should be maintained under 2,500 ppm and carbon monoxide should be less than 20 ppm. Similar to temperature measurement, be sure to take your readings at bird level. If these levels are out of the correct range, check that the barn is properly ventilated with no unplanned openings and that airflow is travelling across the barn, and mixing the incoming air to condition it, rather than dropping outside air onto the birds. Proper understanding and control of gases in the environment can help minimize mortality or health issues, such as roundheart, and help to ensure the overall comfort of the birds.

Importance of feed

Regardless of your farm set up, level of production or breed, it is of utmost importance to get birds eating and drinking right away. Delayed access to feed and water can have adverse effects and compromise the bird’s potential to grow and thrive. The best way to do this is to ensure they provided a comfortable environment, as mentioned above, and that you make the feed and water attractive.

A recent trial, by Hybrid Turkeys, evaluating the effect of getting on feed day one versus day 2 found that differences in average flock weight are evident as soon as 7 days. The trial results showed that flocks on feed day 1 were above the 170 gram Hybrid performance guidelines and those flocks that were delayed feed by 1 day were below the guidelines, thus setting a delayed foundation for growth. The trial also found that 7-day mortality can increase up to 1% in flocks not on feed right away.

Bird comfort and access to feed can have a big impact on a flock’s ability to perform. Therefore, keen attention to temperature, gases and ensuring access to feed right away sets a strong foundation for success.

Water sanitation

Clean sanitized water is one of the most critical, but unfortunately often overlooked, elements in allowing a flock to perform to its full potential. Clean water reduces stress on the animals and helps to prevent common health issues such as Bordetella, E. coli, and salmonella.

The three most common sanitation systems are chlorine dioxide, chlorine with acidification and hydrogen peroxide. Each have their own positive and negative aspects. To make sure the sanitizer is working properly, it is recommended to take water samples routinely (at least once per week). Simply go to the end of your line and get a clean, non-contaminated water sample with your sanitizer present in the water system.

Biosecurity & health

Biosecurity is the planned, methodical approach to securing your farm as safe and disease-free. A crucial component of any biosecurity program is risk management. This means that by identifying and analyzing the risks, you will be equipped to take action, monitor the results, and control the risk. There are a few key areas to keep in mind when developing your biosecurity plan.

Controlling the spread of pathogens outside the barns is your first line of defence in biosecurity. This includes visitor and traffic protocol as well as control of insects, rodents, and wild birds. To control potential carriers of pathogens such as insects, rodents, and wild birds, one common theme is to keep the area around the barns clean of debris or spilled feed. The farm site should also have good water drainage, and barns should be well-ventilated with no pathways for rodents or birds to get into.

Within the farm, it is important to minimize the spread of pathogens. This includes set up of a proper barn entry system with separate personnel clothing. Once inside the barns, cleaning and disinfection will stop the spread of pathogens between flocks.

Conclusion

Keen attention to these key areas of focus will help turkey producers reach a new level of success in performance. Careful focus and investing in your flock at the beginning will lead to better turkeys, better results, better economics, and piece of mind that producers are doing the best they can.