As the poultry sector looks for ways to improve sustainability and energy independence, biogas production from chicken manure is proving to be a practical solution. A case from the Beckhove farm in Germany illustrates how integrating broiler production with biogas technology can yield benefits for both the environment and farm profitability.

From waste to energy: how it works

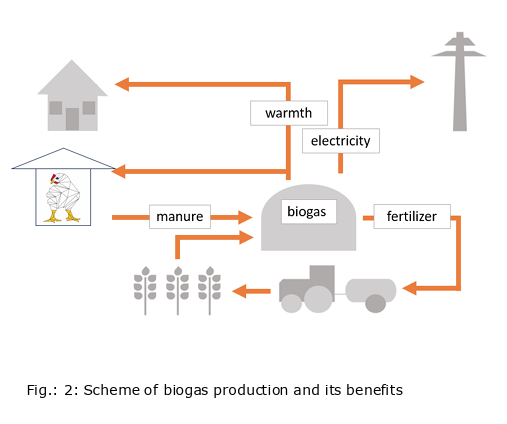

On the Beckhove farm, broiler chickens, pigs, and arable crops are part of an integrated system. Together with a neighboring pig farm, the operation sends animal manure—particularly chicken and pig manure—to an on-site biogas plant. There, under anaerobic conditions, the manure is fermented by bacteria to produce renewable electricity and heat.

The energy is used to power barns and nearby residential buildings. Unlike solar or wind, biogas is a stable, storable energy source that can meet energy demand consistently, especially during peak loads.

Why chicken manure is valuable

Why chicken manure is valuable

Chicken manure has high energy potential, with one ton offering a gas yield comparable to a ton of silage maize. This makes it an attractive resource for biogas producers—especially when the price of maize is high (currently between €25 and €65 per ton).

However, chicken manure also presents a challenge. Its high ammonia content can inhibit the bacteria needed for fermentation. To address this, it’s often co-fermented with other materials such as maize silage, with the optimal mix capping chicken manure at around 30% of the total input.

Environmental and agronomic benefits

Using manure in biogas plants instead of storing it openly results in:

-

Over 90% less methane emissions during decomposition.

-

A valuable organic digestate that can replace expensive mineral fertilizers.

This digestate:

-

Contains key nutrients like nitrogen, phosphorus, potassium, and sulfur.

-

Improves soil structure and humus content, enhancing fertility and water retention.

-

Is more free-flowing and bioavailable than raw manure, making fertilization easier and more precise.

Biogas in the bigger picture

Biogas in the bigger picture

Germany leads Europe with about 10,000 biogas plants, supplying 6% of national electricity. However, the sector faces ongoing challenges:

-

A legal cap limits maize use in biogas feedstock to 40% (dropping to 30% in 2026), prioritizing land for food and feed crops.

-

Government subsidies (EEG 2014) ensure feed-in tariffs or premiums—but only for 20 years. Once expired, many plants may become financially unviable unless energy prices or new funding models improve.

Key takeaways for poultry producers

-

Chicken manure is a valuable energy resource when used in biogas plants, especially under rising energy and feed prices.

-

Co-fermentation helps overcome its biological limitations, unlocking both climate and economic advantages.

-

Farms that invest in closed-loop systems integrating animal production, energy, and crop farming are better positioned for long-term sustainability.

Source:

BroilerNet Factsheet S2-C2-5 – Chicken Manure in the Biogas Plant: Benefits for Farm and Climate

Authors: P. Beckhove, K. von Deylen, J. Malchow, M.L. Vonholdt-Wenker

Funded by the European Union’s Horizon 2020 Programme (Grant No. 101060979)