Modern incubation techniques are critical tools to achieve these goals. By integrating scientific knowledge, precision equipment and data-driven practices, hatcheries can deliver consistent chick quality, improving efficiency and profitability.

Uniformity of day-old chicks is an important factor in modern poultry farming. Chicks that are uniform in size, weight and vitality perform better in the broiler house, need fewer management adjustments and reach market weight more consistently. On the other hand, uneven chick quality often results in variable growth, increased feed conversion ratio (FCR), higher mortality and reduced overall profitability.

Chick quality is influenced not only by the genetic potential of breeder flocks but also by the incubation environment. Modern incubation techniques focus on controlling these environmental factors to minimize variation and ensure that each embryo develops under optimal conditions.

Technological improvements in incubation

Single-stage vs multi-stage incubation

Single stage incubators are now widely adopted. They set eggs of the same embryonic age together allowing precise control of temperature, humidity and ventilation tailored to the specific stage of embryonic development. This approach helps reduce variation and results in more uniform hatches.

Multi-stage incubators, instead, usually mix eggs of different developmental stages in one machine. Although they are cost-effective, they create challenges in maintaining hygiene, sanitation and uniform temperature and humidity.

Digital sensing and automation

Modern incubators are equipped with advanced sensors that continuously monitor temperature, humidity, carbon dioxide and airflow, which help to maintain incubation parameters properly according to the needs of the hatching egg. The automated turning system helps distribute heat and temperature uniformly to all eggs. Automation ensures that even small fluctuations are corrected immediately creating a stable environment for all eggs.

Data integration and smart hatcheries

Nowadays modern hatcheries are moving toward data-driven operations where every stage of the incubation process is monitored, analyzed and optimized in real time. This transformation is made possible by data integration. Data integration is the process of collecting information from multiple sources such as egg storage rooms, setters, hatchers, fresh air cabinets, chicks handling units and combining it into a centralized digital platform. Sensors installed in storage rooms, incubators and hatchers continuously track critical parameters such as temperature, humidity, ventilation rate, CO₂ and egg weight loss. Many companies provide software platforms that support data integration, monitoring and smart hatchery management, for example, Eagle Trax™, by Petersime.

Temperature control for uniform development

Embryos are highly sensitive to temperature fluctuations. Excessively high temperature can accelerate embryonic development and cause premature hatching, while excessively low temperature can delay hatching or result in weak chicks.

Optimal range. For proper incubation the optimal temperature range inside the incubator is 37.5-37.8 °C.

Eggshell temperature monitoring. Eggshell temperature monitoring is an important tool for evaluating whether incubation conditions are appropriate. Hatcheries can use infrared thermometer or egg temperature sensor such as the OvoScan system instead of relying solely on ambient air measurements. This method ensures that embryos are developing at a uniform rate. Eggshell temperature standard is in the 37.6–38.3 °C range.

Airflow management. Uniform airflow management is crucial for ensuring proper heat distribution, preventing hot and cold spots and reducing variation between trays.

By carefully managing temperature profiles throughout the incubation, hatchery managers can achieve more synchronized hatches and increase chick uniformity.

Humidity and egg weight loss

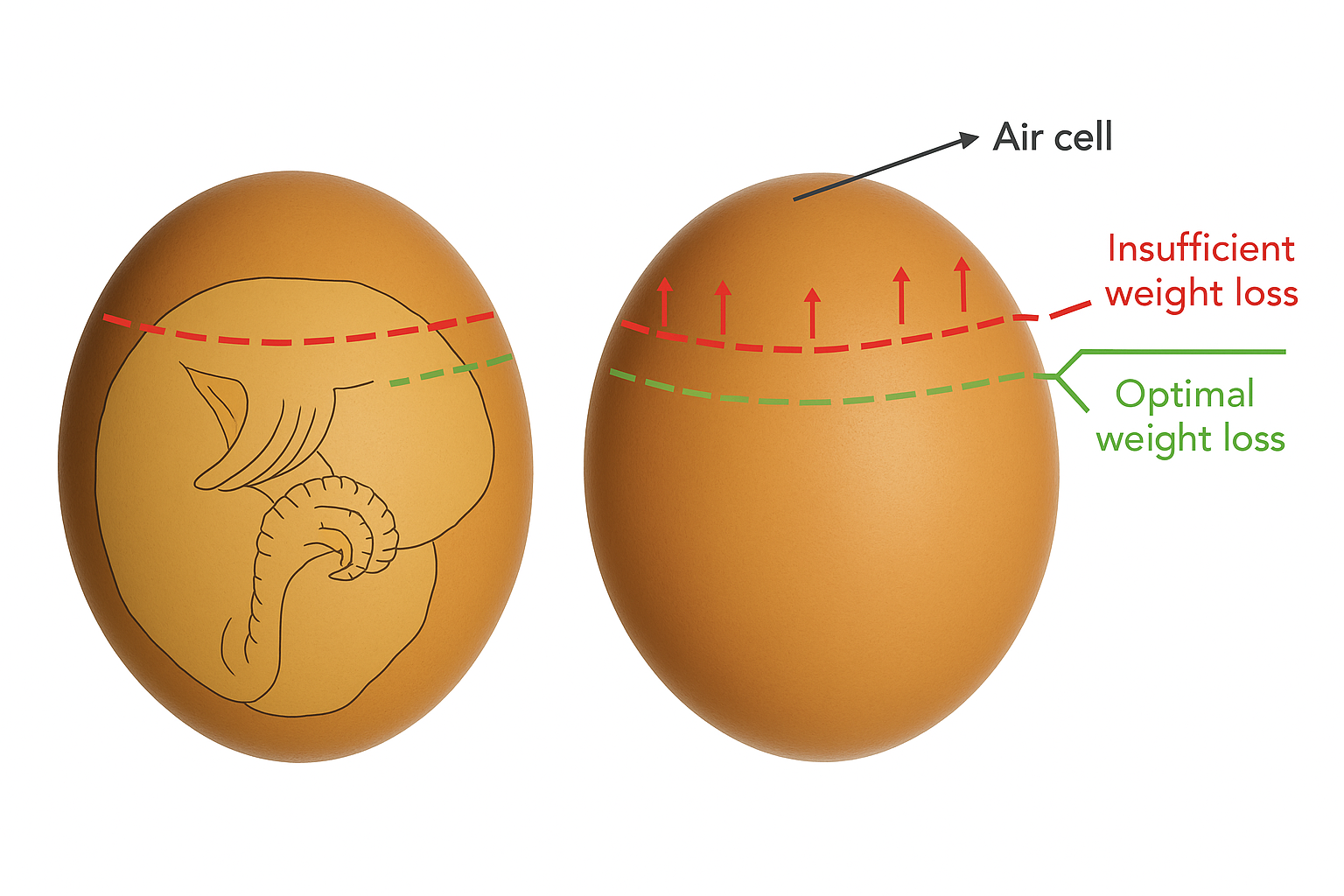

Humidity control in the incubator is very important because it directly affects egg weight loss, which is crucial for chick quality. Eggs usually need to lose 11–13% of their weight from laying to 18 days of incubation to achieve proper air cell development.

Low humidity. Low humidity leads to excessive water loss, which can result in dehydrated chicks and a reduced chick yield percentage.

High humidity. Excessively high humidity prevents adequate water loss, which can produce chicks with poor yolk absorption, improper navel closure, underdeveloped respiratory systems and, ultimately, an increased chick yield percentage.

Modern techniques. Modern hatcheries now use automatic humidification and dehumidification systems, as well as ultra-humidification systems, that respond to real-time data, ensuring optimal egg weight loss throughout incubation.

The role of carbon dioxide (CO₂) and ventilation

Embryos need proper oxygen supply during incubation (minimum 21% oxygen) and they produce CO₂ as they develop so proper ventilation is essential. Adequate oxygen intake and the efficient removal of carbon dioxide via gas exchange through the porous eggshell are essential for normal development, hatching performance and chick quality. Insufficient oxygen supply can lead to metabolic imbalance and developmental abnormalities. High CO₂ level (1.2%) during early incubation accelerates embryo growth, but must be carefully balanced to avoid suffocation. Controlled ventilation systems in modern incubators regulate oxygen inflow and CO₂ outflow dynamically. Proper ventilation is therefore crucial for better hatch performance and good quality chick production.

Egg turning and positioning

Egg turning during incubation is very important to prevent embryos from sticking to the shell membrane and to ensure proper positioning before pipping. Incubators are programmed to turn eggs gently and consistently usually once per hour with a turning angle of 43–45°. Computerized systems help ensure that all eggs receive identical turning conditions, reducing malposition and increasing uniformity at hatch.

Hatch window and synchronization

The time span between the first and last chick hatching is called the hatch window and is a key measure for incubation success. The ideal hatch window is 24–30 hours. If the hatch window is too wide, it results in weak, dehydrated early chicks and late chicks that struggle to survive.

Post-hatch handling and chick quality assessment

The incubation process doesn’t end at hatch. How chicks are handled post-hatch has a major impact on their uniformity. Prompt removal of chicks from the incubator is essential, as delays can lead to dehydration and increased variability. During the holding period before transport, chicks should be kept at a temperature of 25–28 °C with good ventilation to maintain optimal condition. In addition, most commercial hatcheries use the Pasgar scoring system to evaluate chick quality, assessing factors such as vitality, navel closure, alertness, leg strength, and overall uniformity before delivery.

The future of incubation: precision and sustainability

Incubation technology is continuously advancing, with current innovations focusing on sustainability and precision. Modern embryo-responsive incubation systems can adjust conditions based on real-time embryo signals; for example, Petersime uses the OvoScan and HatchScan systems. Hatchery automation is also expanding, covering egg handling, grading, transfer, and chick counting, which reduces human error and labor costs. Companies such as Viscon, Vencomatic Group, HatchTech, and Innovatech now provide comprehensive hatchery automation equipment. In addition, energy-efficient incubators are being developed to reduce operational costs while maintaining stable incubation conditions. These innovations are expected to further improve chick quality, reduce variability, and enable hatcheries to meet the growing global demand for poultry products.

Conclusion

Modern incubation techniques have revolutionized the process of chick production in commercial hatcheries. For commercial poultry operations, investing in modern incubation practices is no longer optional, it is essential. Uniform, healthy chicks not only perform better on the farm but also reduce production costs, improve welfare and maximize profitability.

In an industry where every percentage point matters, the adoption of modern incubation techniques is the surest path to consistent success.