Orbem has developed a groundbreaking solution to address one of the most significant ethical and economic challenges in the global poultry industry: the culling of day-old male chicks from layer breeds. Orbem’s technology provides a contactless, accurate, and scalable method for in-ovo sex determination, allowing hatcheries to operate more ethically and efficiently.

ethical and economic challenges in the global poultry industry: the culling of day-old male chicks from layer breeds. Orbem’s technology provides a contactless, accurate, and scalable method for in-ovo sex determination, allowing hatcheries to operate more ethically and efficiently.

Orbem’s non-invasive in-ovo sexing technology future-proofs hatcheries

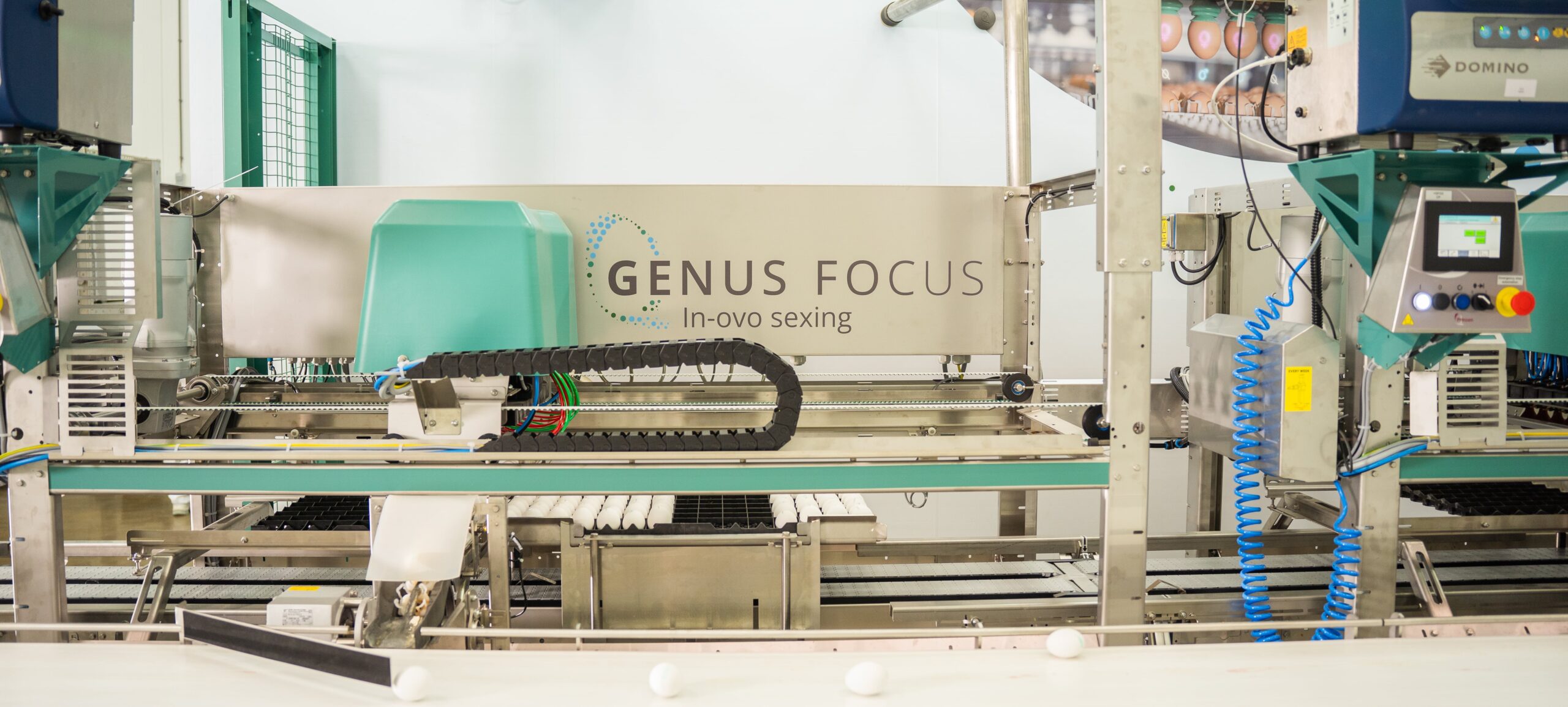

The Genus Focus, our in-ovo sexing solution, combines two powerful technologies: Magnetic Resonance Imaging (MRI) and Artificial Intelligence (AI).

Magnetic Resonance Imaging (MRI) – Trusted for decades in human medicine for its safety and precision, MRI allows us to generate a high-resolution image of the interior of an egg. Critically, this process is completely contactless. It does not use radiation or require any penetration of the eggshell, meaning the embryo is not touched, stressed, or harmed in any way.

Artificial Intelligence (AI) – Our proprietary AI platform is the brain of the operation. It has been trained on a massive dataset of millions of MRI scans. The AI analyzes each new scan in real-time to detect subtle, sex-specific biological markers within the developing embryo. It can make a decision with exceptionally high accuracy in just one second. Because our AI learns from every scan that is made, our solution is uniquely equipped to get better and better over time – an exceptional feature we owe to the power of Machine Learning.

The fully automated process involves eggs moving on a conveyor belt through the Genus Focus scanner. After the one-second scan and AI analysis, the system automatically sorts the eggs. Male-identified eggs are removed from the incubation process immediately and can be repurposed.

Key benefits of Orbem’s technology

Orbem delivers a suite of compelling benefits that span ethics, economics, and animal performance.

- Ethical integrity and animal welfare: The complete elimination of the need to cull male chicks allows hatcheries to comply with animal welfare legislation, such as Germany’s “Tierschutzgesetz” (Animal Welfare Act), and meet the growing consumer demand for ethically produced food.

- Improved chick quality and performance: A crucial and powerful benefit reported by our partners is the enhanced quality of the female chicks that hatch. Because the Orbem process is stress-free, it avoids negatively impacting the embryo’s development. This results in hatched chicks that are more robust, healthier, and more vital. Consequently, our partners experience reduced mortality rates during the critical first weeks in the rearing houses, leading to better overall flock performance.

- Data-driven insights: The Genus Focus system is also a data collection tool. It provides valuable data on fertility rates and other quality metrics, giving hatchery managers unprecedented insight to optimize their breeding and incubation processes for better overall results. Our imaging solution allows us to collect a broad range of data points from the inside of an egg, allowing hatcheries to go beyond in-ovo sexing, and profit from early fertilization status detection or phenotyping as well.

- Economic and operational efficiency: Our solution provides substantial operational advantages. By identifying and removing male eggs (around day 12 of incubation), hatcheries save significant resources on incubation space and downstream costs like vaccinations and manual sexing labor. The high-speed, automated system seamlessly integrates into existing hatchery workflows, increasing throughput and efficiency, future-proofing operations.

In summary, Orbem’s technology offers a comprehensive solution that aligns ethical responsibility with economic profitability. It empowers hatcheries to build a more sustainable, efficient, and humane future for poultry production.