The hatchery is where we create the optimum conditions for life to develop. Although we are talking about the development of embryos, there are many other – unwanted – forms of life, like fungi and bacteria, which can also take advantage of these conditions in the hatchery. That makes hygiene an important concern.

It is relatively easy to create sanitary barriers on the floor of a hatchery. Air, however, is a difficult carrier to control.The air pressure system in the hatchery was originally created as a hygiene measure. Contamination in the hatchery progresses in tandem with the incubation process: setting = “clean”, hatch = “dirty”. That makes the parts of the building easy to define. Air should move consistently in one direction – from “clean” to “dirty”. That is logical, and it sounds easy – but it is not.

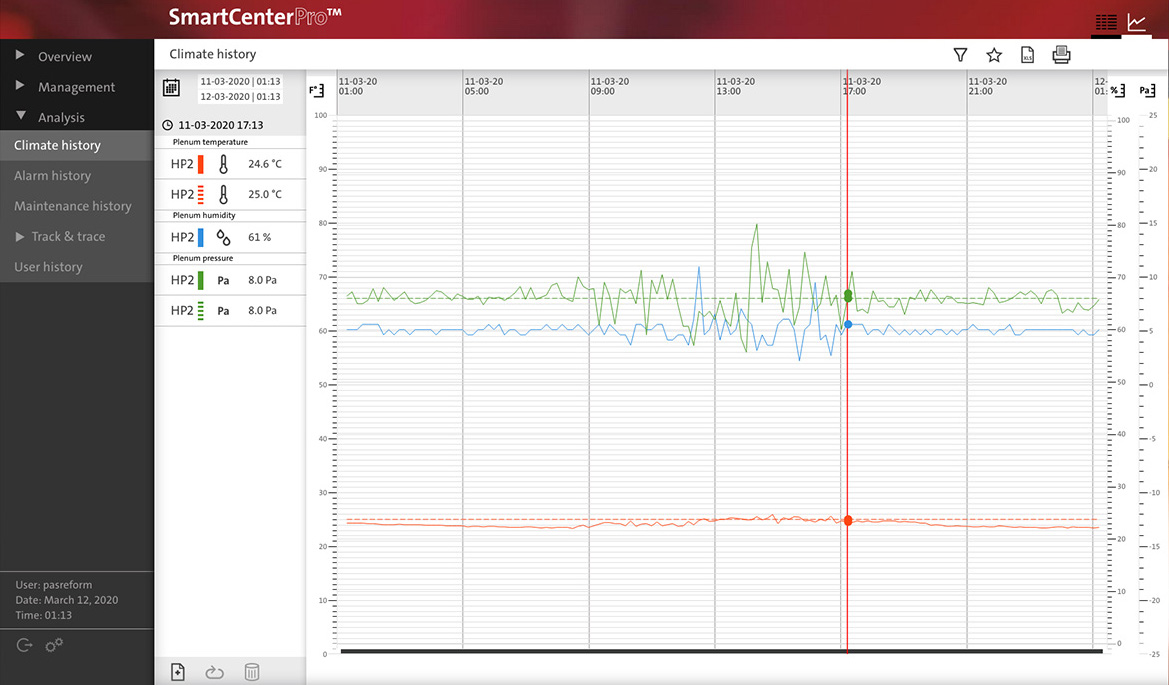

Forcing the air to go in one direction requires a system of devices that measure and control the air pressure, so that it goes from high in the “clean” part to lower in the “dirty” part. The hatchery building is a complex construction, with many obstacles and opportunities for leakages. To make the system work requires a certain amount of discipline, so that the air is forced to move as planned. In addition, fresh air, preconditioned by the Air Handling Units, is a costly product and must be used economically.

The pressure differences are not only of hygienic value.The difference in air pressure between the incubator air inlet and the outlet supports the ventilation rate in the machine. But more does not necessarily mean better. The air supply must be balanced by an adequate air exhaust.

A too high pressure difference may create a short-cut in the air circuit. Air will take the easiest way from the inlet to the exhaust and leave dead spots elsewhere – causing poor uniformity of temperature and ventilation.

The balance – an equilibrium between supply and removal – has a dynamic character. Demand for air exchange fluctuates, depending on the phase of the incubation cycle and volume of the load. The hatchery’s air pressure control system must be reactive and flexible. The air supply demand for the entire installation also changes depending on the number of machines in use.

The measurements of air pressure at supply and exhaust are relative values. To measure them we use a reference: the external air pressure. This is measured by sensors located outdoors, where they are potentially exposed to the wind. It is essential to make sure that this reference is reliable, so it is very important to ensure that the reference sensors are correctly located and protected.

Advice:

- Make sure the air flow in the building is in line with the concept.

- Always keep all doors and windows closed.

- Control the status of fans used to maintain the pressure system in the building.

- Pay attention to the technical status of Air Handling Units. Control their filters, heating and cooling coils and motors.

- Maintain the incubator’s inlet and exhaust pressures as recommended by the machine manufacturer.

- Make sure the incubators are well sealed and that no air escapes though the dampers of machines that are not in use.

- Install the reference pressure sensors so that they are out of the direct influence of the wind.

- In case of doubt, check the distribution of egg shell temperatures in the incubators and the hatch result in different parts of the hatcher. An increased spread may be an indication of an incorrect pressure ratio between inlet and exhaust.