CAS helps reduce the stress in animals. This is a humane approach and many poultry companies are starting to take note. Animal well-being extends beyond the farm and is a top priority. A humane approach can result in operations that are more efficient, in better end-product quality and higher consumer satisfaction.

Controlled atmosphere stunning (CAS) is a technology designed to lower stress in animals before evisceration. Birds are transported into an area where the air is removed from their immediate surroundings and replaced with a mixture of oxygen and carbon dioxide.

Solving challenges

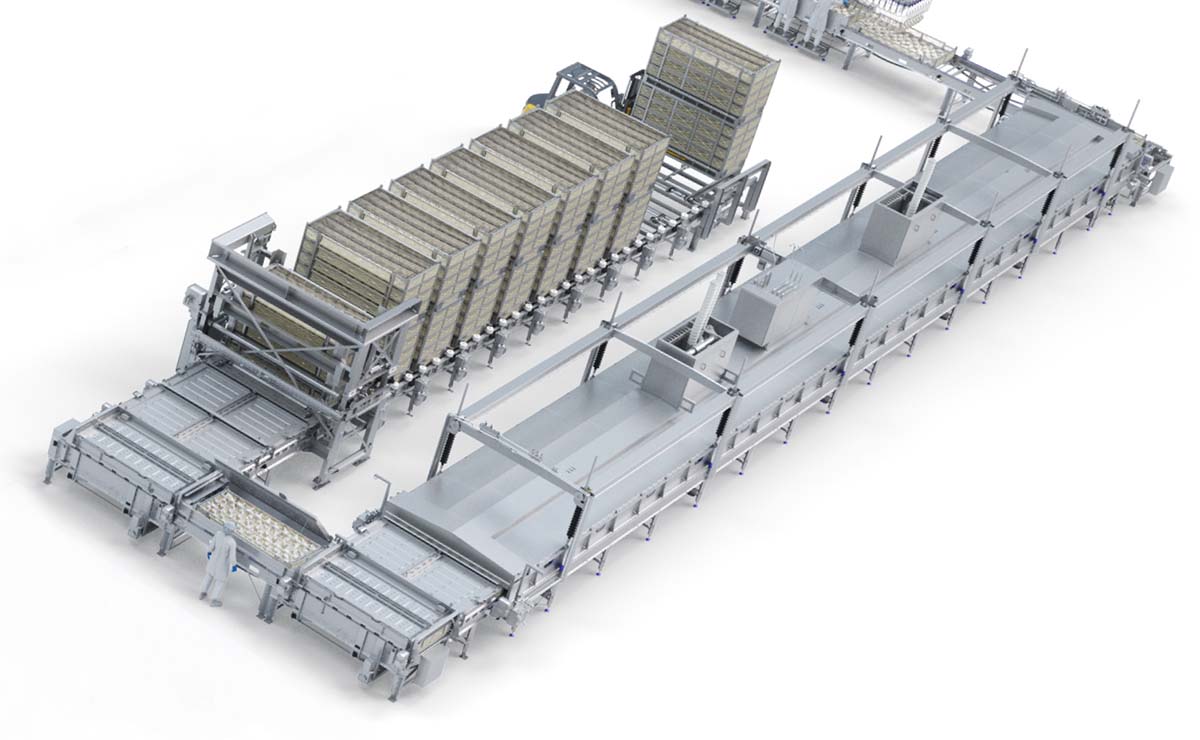

The air-stunning technique is an example of how equipment can help solve challenges and issues on the line. There are various advantages to air stunning, from both an animal well-being and operational standpoint. The shackling of live broilers to the line is very stressful for both people and birds, and damage to the chicken is not far away. Now, with controlled atmosphere stunning, the birds come in the transport container and stay in there. It’s a much better environment for both employees and chicken. A CAS system also offers benefits to the processors. It can be implemented relatively easily at the farm and/or plant without negatively affecting line speeds.

Shift in priorities

Tim van Schaik, poultry product manager for Marel says, “We definitely have seen a shift in priorities with regards to animal well-being over the last few years, especially with customers who are connected and/or suppliers to national foodservice brands as well as high-end products, such as organic or antibiotic-free product. We feel that the general public, and of course NGOs, are becoming more and more aware of animal well-being.”

The same time and level

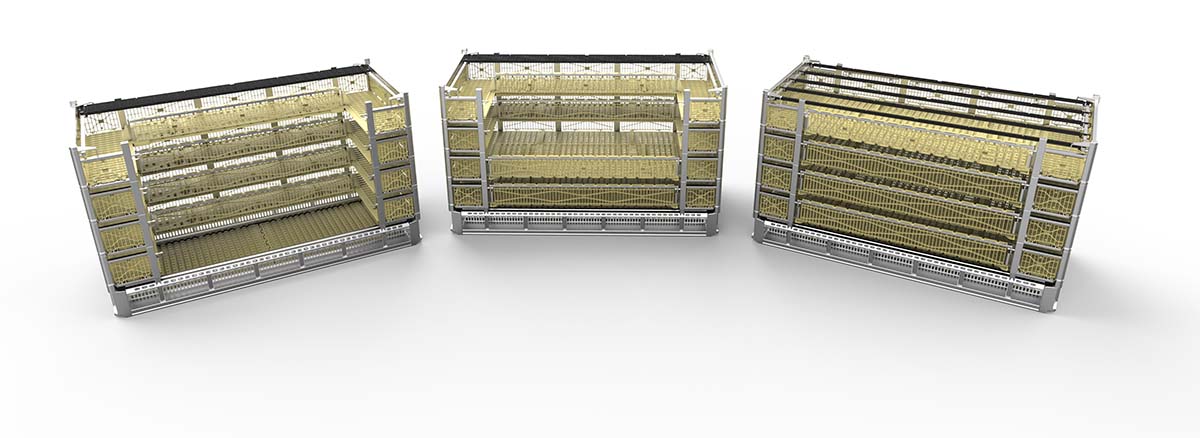

Van Schaik says that ATLAS includes a SmartStack module that provides more space to each bird and increased loading capacity for fewer truck movements and less CO2 emissions. The transport from farm to processing plant becomes a lot less stressful for the broilers. They stay calm in their trays and won’t sustain any injuries such as broken wings or bruises. After a certain amount of rest time in the dark lairage, birds enter the anesthetization stage. Marel’s CAS SmoothFlow uses a mixture of CO2 and O2 in a multiphase process, in a single straight horizontal line. “This smooth flow virtually enables an even more controlled atmosphere during the process of stunning, ensuring the best possible end-product quality. Stunned broilers leave the system still maintaining their physiological functions,” he explains, adding that the straight in-line setup is also a continuous process that assigns the same anesthetization time and atmosphere level to every single broiler.

Measurable improvements

European processors were already convinced of the benefits of Marel’s CAS SmoothFlow system for a long time. Recently, large American processors have committed to converting all their poultry processing plants to CAS systems to replace the more traditional method, electrical stunning. Tim van Schaik says, “Since implementing the CAS technology, we’re seeing measurable poultry welfare improvements throughout the process, as well as improvements in product quality. Our CAS SmoothFlow system uses both carbon dioxide and oxygen in the mix, which creates less stress on the birds as they go through the chambers. The difference is night and day. Our CAS system helps reduce handling stress with chickens, resulting in a higher-quality, more consistent product.”