It is Hubbard’s genetic commitment to offer a wide range of products ranging from conventional cost-efficient broilers to slow(er) growing Premium chickens. It is clear that Hubbard’s genetic programs are designed and dedicated to meet the growing challenges of our civilization by providing efficient, healthy, high-quality and tasty chicken meat for the world’s growing population.

A rapidly changing world, demanding more

The world population is growing at a frightening level of 220,000 persons per day (or 80 million per year). Asia and Africa are the regions likely to experience the fastest growth. We can also see a transition from a staple diet of cereals and vegetables in developing countries to a diet based on further processed foods consumed by families in some of the most developed economies resulting in much higher food expenditure by family per week.

Some may be looking for a return to organic farming methods to feed the growing world population, but to our opinion this just answers a specific demand for a niche market and will not be the answer to feed a growing human population sustainably.

Main R&D objectives

Within Hubbard, as a primary broiler breeder, it is our main objective to continue to improve the efficiency and profitability of the broiler industry which is challenged by more and more difficult and complex circumstances; cost of raw materials, on-going disease challenges around the world, increased pressure on animal welfare and use of antibiotics and uncertainties about market developments in some regions/countries. At Hubbard, we sincerely believe that it is our responsibility to help the industry to provide all the elements for its future growth. Genetic selection is by definition actively involved in the development to produce more with fewer resources, making the broilers more efficient to produce good quality meat for different market. This accounts for as well as Conventional broilers as for Premium chickens of the high-end market.

Within Hubbard, as a primary broiler breeder, it is our main objective to continue to improve the efficiency and profitability of the broiler industry which is challenged by more and more difficult and complex circumstances; cost of raw materials, on-going disease challenges around the world, increased pressure on animal welfare and use of antibiotics and uncertainties about market developments in some regions/countries. At Hubbard, we sincerely believe that it is our responsibility to help the industry to provide all the elements for its future growth. Genetic selection is by definition actively involved in the development to produce more with fewer resources, making the broilers more efficient to produce good quality meat for different market. This accounts for as well as Conventional broilers as for Premium chickens of the high-end market.

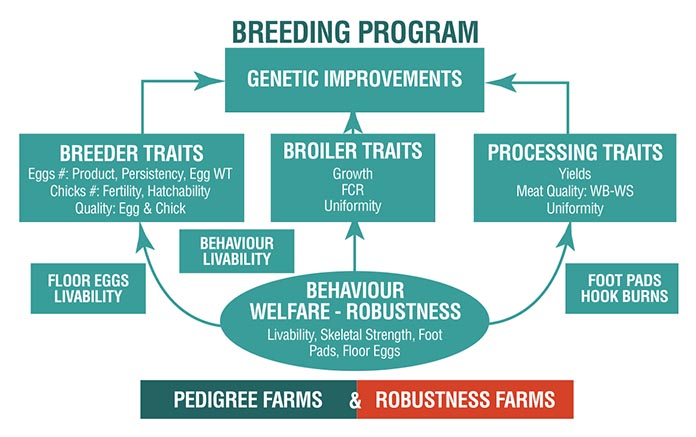

Selection for the best feed efficiency has been general practice within Hubbard for many years, which is proven by the actual performance of our products, being recognised as, or among, the most efficient products in the field. Selecting for feed efficiency has the final aim to improve the profitability of the broiler industry, but also targets a more sustainable future. Hubbard is proactively embracing this challenge to make the poultry industry more sustainable over time, to be able to continue to feed the growing world population. At Hubbard we actively contribute to this objective by selecting for more saleable meat with less feed, but on top we are also actively working on the hardiness and robustness of the products we offer. The ongoing challenge for a primary broiler breeding company is to make sure that the R&D strategies not only are related to commercial broiler performance (live, processing), broiler robustness and welfare performance, but also to breeder performance. Hatching egg numbers, a balanced egg weight curve, good egg shell quality, high percentage of hatch are key traits in the female lines breeding programs. In the male lines the breeder performance focus is more on fertility measured under natural mating conditions.

Matching market requirements and R&D

Continuously upgrading breeding programs in order to match changing market requirements is the main goal of the R&D team of a primary breeding company. One of the biggest challenges that geneticists are facing is running breeding programs where the Elite level pure lines flocks are kept under top conditions (in order to maximise the expression of the genetic potential as well as guaranteeing a disease-free status) and, at the same time, breeding for robustness and the ability to perform under a variety of environments.

This difficult equation is tackled within Hubbard by:

- breeding the pure lines in highly bio-secure environments,

- placing pedigree sibs (the relatives of selection candidates) in test facilities in challenging commercial conditions.

In both types of facilities all chicks are grown as broilers. The pedigree sib-tests are operated in Europe (temperate climate conditions) and in South-East Asia (hot and humid conditions). All the information recorded on an individual basis is integrated into the pure lines genetic index evaluation. Evaluating genetic potential under challenging commercial conditions is especially important for robustness and welfare traits such as liveability, lower frequency of leg disorders (twisted legs, tibial dyschondroplasia), hock burn and foot pad lesions.

A variety of traits is measured in the multiple environments design (pure line facilities plus challenging commercial conditions sib-testing): leg defects (valgus, varus and rotated tibia), tibial dyschondroplasia, gait score, foot pad lesions and hock burn. Mortality is recorded by cause of death (ascites, flip-over, runting, etc.). Blood oxygen saturation, a trait related to resistance to ascites, is also recorded on all selection candidates. All these data are analysed with state-of-the-art statistical methods allowing identifying the individuals showing the best genetic potential for robustness and welfare traits in different environments.

To match market requirements, geneticists also have to include many breeding objectives in the pure line programs. As mentioned, one of the most important objectives is Feed Conversion Rate (FCR). Since the early 80’s, Hubbard has been delivering to the industry significant gains in FCR. Besides the conventional way of selection for FCR (i.e. by using individual cages), RFID (Radio Frequency Identification) technology allows measuring “whole life FCR” of individual birds kept in group pens on the floor, much closer to field conditions. This technology also gives access to feeding behaviour traits (meals/day, meal size, etc.).

Modern broiler R&D also includes selecting for better breast, legs, total meat yields and meat quality. To achieve this goal selection candidates are evaluated for breast yield by using a conformation score (subjective scoring assessing breast length, width, shape) and CT-technology in the pedigree lines. On top total meat, yield and meat quality (e.g. wooden breast, white striping, etc.) are evaluated by processing and deboning samples of the sibs. Hubbard geneticists are closely collaborating with research institutes in order to investigate the potential of meat quality criteria and support a PhD study with the French research institute INRA on wooden breast and white striping.

Modern broiler R&D also includes selecting for better breast, legs, total meat yields and meat quality. To achieve this goal selection candidates are evaluated for breast yield by using a conformation score (subjective scoring assessing breast length, width, shape) and CT-technology in the pedigree lines. On top total meat, yield and meat quality (e.g. wooden breast, white striping, etc.) are evaluated by processing and deboning samples of the sibs. Hubbard geneticists are closely collaborating with research institutes in order to investigate the potential of meat quality criteria and support a PhD study with the French research institute INRA on wooden breast and white striping.

By maintaining a close contact with the different broiler markets and customers, selection goals will keep on being adjusted to match future needs. At Hubbard we will work on further intensifying the use of techniques and state-of-the-art breeding tools such as genomics, statistical methods, RFID technology and novel technologies such as genotyping by sequencing which is being looked at with prudent expectation.