Corn is usually ground locally at the feed mill, while soybean meal is pre-processed and feed mills have little control over its particle size (PS). Because feed mills have greater control over energy ingredients such as wheat, barley corn and other cereal grains, these can be ground to the PS goal of the mill.

By identifying an optimum corn PS for a given sector of poultry, there is an opportunity to maximize feed efficiency and nutrient absorption for pullets, layers and broilers. However, finder grinding decreases throughput (tons per hour), flow-ability and will slow mill production. Increasing PS from 600 μm to 1200 μm in a mill producing 29,000 tonnes annually saves $11,000 in electrical costs alone (CPM, 2017).

Two types of equipment are commonly used to reduce PS; hammer mill and roller mill. Generally, the hammer mill is used more frequently because of lower maintenance costs and a simpler user interface. Hammer mills consist of flailing metal rods, swinging in a chamber forcing the grain thorough a screen of a given size. Roller mills have one or more sets of horizontal rollers with the distance between rollers adjusted to arrive at the desired PS. Due to constant pressure between the rollers, grain size tends to be more uniform. The fineness of dietary cereal grain PS plays a large role in pellet quality and bird performance. Poor pellet quality resulting from improper PS cereals decreases the benefits broilers receive from the pelleting process. Additionally, different cereal grains have unique PS that is achieved with a given screen size indicating that even with a specific PS goal, mills likely will need to adjust their equipment when using different cereal grains for accurate PS realization. Broiler and layers alike have been shown to have a preference for greater PS as the bird grows with age. Furthermore, PS has been shown to be more important when feeding mash diets rather than as crumbles or pellets.

Little research has been conducted specifically looking at how corn PS affects pullet growth performance before entering into the laying hen stage of life. Light weight pullets at 18 weeks of age have been reported to consume less feed, reach sexual maturity later, lay smaller eggs and lay less egg mass by 70 weeks of age than heavier pullets. Recently, a study by Frikha et al. (2011) evaluated brown egg laying pullets fed either corn or wheat (at 50% of their diet) ground through a 6-, 8-, or 10-mm screen and found finely ground corn at 929 μm geometric mean diameter (GMD) was significantly better than greater corn PS (991 μm and 1042 μm GMD) and all wheat treatments (967, 1119, 1216 μm) were better than corn for pullet BWG and FC from placement through 6 weeks of age. Typically commercial pullet and laying hens are fed mash diets where grinding feed ingredients is a large portion of fabrication costs. Therefore mash ingredient uniformity is an important consideration as birds choose larger particles if possible potentially altering nutrient composition of the feed they eat.

Materials and methods

Corn milling and efficiency

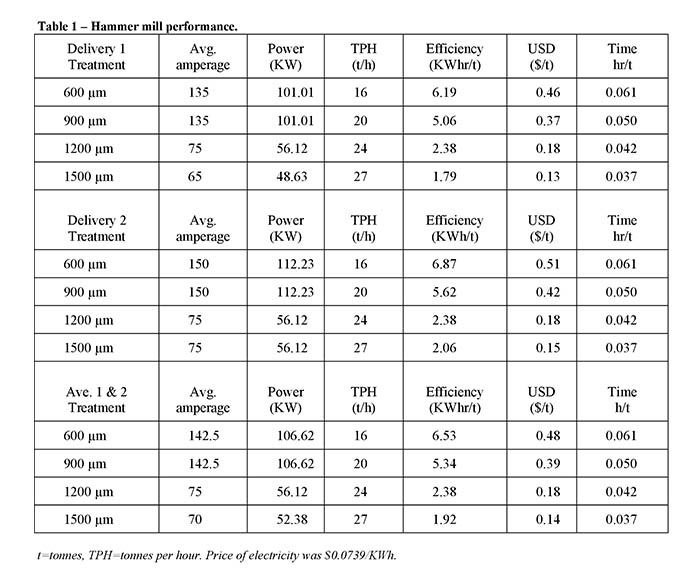

Wenger Feeds, LLC ground whole corn into four treatment PS (600, 900, 1200, and 1500 μm) at for two deliveries. Both Delivery 1 and Delivery 2 were ground using two hammer mills (both Sprout, model #3818), one fitted with small and large screen hole diameters. The medium grind hammer mill was used to grind the 600 μm and 900 μm, with a 150-HP variable frequency drive (VFD) running at a maximum of 1800 revolutions per minute (RPM). The 1200 μm and 1500 μm corn were ground on the coarse hammer mill, with a 100-HP motor and the VFD at a maximum of 1200 RPM. The VFD allows the mill to fine tune the PS. Wenger Feeds, LLC collected and recorded information regarding the speed and amperage of the two respective hammer mill motors during the grinding, as well as throughput in tonnes per hr (TPH), efficiency (KWh/tonne), cost per KWhr and cost ($/tonne) and speed (hr/tonne) to grind whole corn to the treatment GMM.

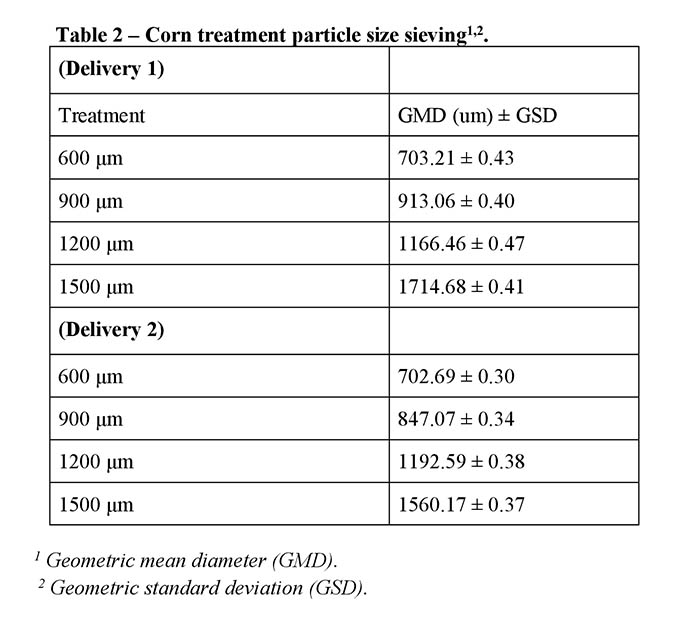

Sieving and calculations

To determine the actual PS distribution of the 600, 900, 1200, and 1500 μm corn, three samples were taken of each corn treatment from each Delivery from random locations in the 454 kg delivery totes. The sieving and PS measurements for all samples were measured in accordance with ASABE (2008) procedures. Using a W.S. Tyler sieve shaker (W.S. Tyler Company, Cleveland, OH) with three replicates of 100 g each, for a total of twenty-four 100 g samples. Samples were shaken for 10 minutes each, with tare weights of individual sieves were taken before shaking, and at the conclusion of sieving. The mass of each of the sample materials were recorded, and percent distribution, GMD, and geometric standard deviation (GSD) were calculated.

Birds and housing

Day old Hy-Line W-36 chicks (325) were acquired from Hy-Line USA and randomly placed into 13 pullet cages, with 25 birds per cage, at 142 cm2 per bird. There were three corn particle size treatments with 4 replicate cages for each of the 600 and 1500 μm corn and 5 replicate cages of the 900 μm corn treatment diet. Management practices followed the Hy-Line management guide with a dark grow to dark lay program created for 41N latitude following Hy-Line’s lighting guide (Hy-Line, 2016). All feed and water were provided ad libitum throughout the entire study. At 10 days of age, all birds were hot blade beak trimmed to avoid feather picking or cannibalism later in life. At five weeks of age, each cage of birds was weighed, separated into two cages of 12-13 birds per cage, at 284 cm2 per bird and feed intake and feed conversion were calculated (600 and 1500 μm treatments had 8 replicate cages each and the 900 μm treatment had 10 replicate cages). Birds were fed a standard phase fed dietary program with the same energy and nutrient levels in all diets with only GMD of corn varying as the treatment (600, 900, or 1500 μm). Birds were fed a starter diets from 1-5 weeks of age, grower diets from 5-10 weeks of age, developer diets from 10-17 weeks of age and pre-lay diets from 17-19 weeks of age. At each diet change, birds were weighed and feed intake was measured. All study procedures and methods for this study were approved by The Pennsylvania State University Institutional Animal Care and Use Committee (IACUC Protocol #46838).

Body weight, growth performance, and organ measurements:

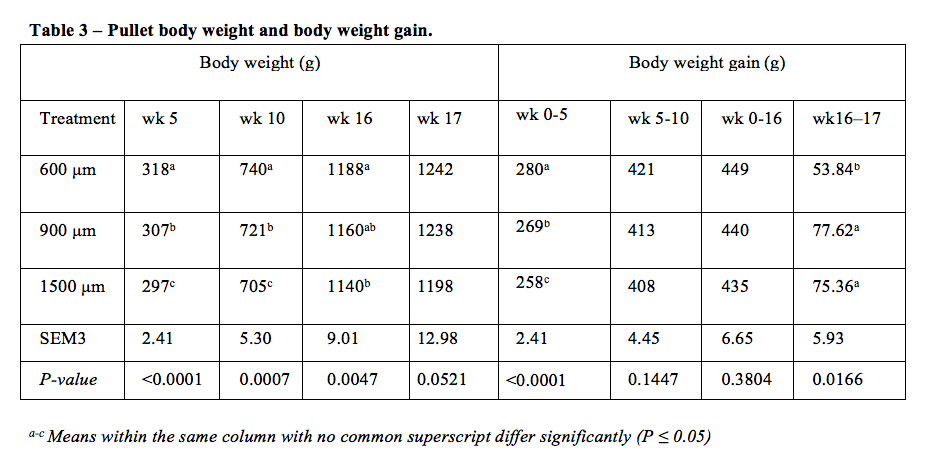

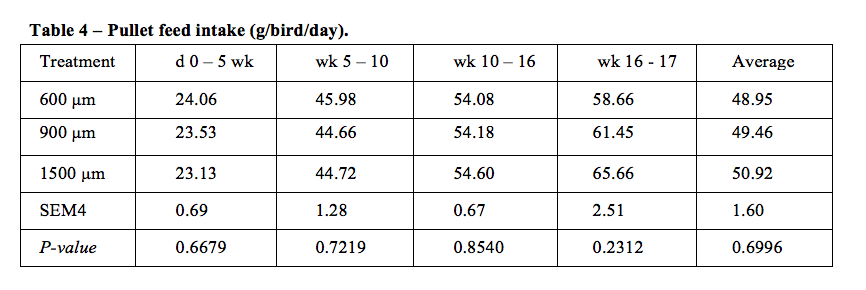

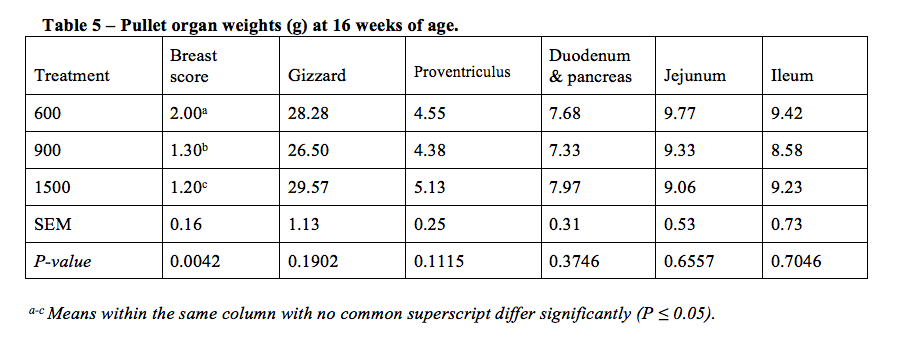

Birds were weighed as a cage group at placement, 5, 10, 16, and 17 weeks of age. From these weights, BWG from placement through 5 weeks, 5 – 10 weeks, 10 – 16 weeks, and 16 – 17 weeks was calculated. At these same time points, feed intake was measured as g/bd/d. At 16 weeks of age (one week before lighting was increased to 13:11 L:D from 12:12 L:D), 6 pullets per treatment were randomly selected and euthanized to evaluate growth and reproductive development utilizing a 0-3 breast score (Hy-Line, 2016). Gastrointestinal organ weights (g) were measured for the gizzard, proventriculus, and small intestine (duodenum, ileum, and jejunum), ceca, and lengths (cm) were measured for the small intestine sections. Additionally, the ovary was weighed and examined to quantify differences between treatments in reproductive maturation, such as larger ovary cortical weight by 16 weeks of age.

Statistical analysis:

Data was analyzed with a one-way ANOVA using the MIXED procedure of SAS 9.4 (SAS Institute, 2013). Means were deemed significant when P≤0.05. Tukey’s test was used for multiple mean comparisons when significant differences were determined between treatments.

Results and discussion

Corn Milling and efficiency:

The average milling performance reported in Table 1 indicated the larger HP motor ran at a higher rpm, utilized greater amperage (142.5) resulting in more power to grind the 600 and 900 μm PS at 106.62 KW. The throughput in tonnes per hour averaged 16 and 20 t/h for the 600 and 900 μm corn, respectively, which was considerably less than the throughput of the 1200 and 1500 μm corn at 24 and 27 t/h each. Efficiency was much better for the larger PS corn compared to the 600 μm requiring less KWh/t. Cost was reduced per tonne utilizing the local price of $0.0739/KWh, when grinding larger PS corn, and more expensive for the higher HP motor and smaller 900 and 600 μm PS corn. Another expense in the mill is the processing time which indicated the smallest 600 μm corn took nearly twice the time to grind per tonne compared to the 1500 μm corn (Table 1). The geometric mean diameter (GMD) of the corn generated for the study was very close to the treatment goals (Table 2) within 100 μm or less of the PS goals. The one exception was the 1500 μm delivery 1 corn with an actual GMD of 1714.68 μm corn. Both deliver 1 and 2 corn treatments had very low geometic standard deviations (GSD) between 0.30 and 0.47 with the delivery 2 corn lower (0.30- 0.38) than delivery 1 (0.40 -0.48), but both were low herein compared that reported by Reece et al. (1985) where a roller mill GSD (2.23) and hammer mill GSD (2.35) were compared for ground corn.

Pullet growth and body composition

Pullet body weight was consistently higher (P<0.05) for the 600 μm corn fed treatment at 5, 10 and 16 wk of age compared to the 900 and 1500 μm treatments, and the 900 μm birds were greater than the 1500 μm (Table 3). This trend was also observed at 17 weeks of age (P=0.0521). Body weight gain follow the same pattern form day 0 to 5 weeks with the 600 μm birds gaining more than the 900, and the 900 more than the 1500 μm corn treatment (P<0.0001). However, from 16 to 17 weeks there appeared to be some catch up gain and the 900 and 1500 μm treatments gained more than the 600 μm fed birds (P<0.0166). There were no significant differences in feed intake between the treatments for the length of the study, suggesting the diets and nutrients were utilized differently between the different treatment birds to realize the differences in body weight that were observed (Table 4).

While there were no statistical differences in digestive tract or reproductive tract organ dimensions, weights or weight expressed as a percentage of body weight between the corn treatments (Table 5). However, we did observe greater fleshing among the 600 μm fed pullets at 16 weeks of age compared to those fed 900 or 1500 μm corn, measured using the HyLine management guide scoring procedures (P=0.0042).

Conclusions

These results would suggest for pullet rearing 600 μm corn would be beneficial for meeting body weight and body weight gain from day 0 to 10 weeks of age. After 10 weeks of age either 600 or 900 μm corn will achieve similar results, but 1500 μm corn will result in lower body weight and gain. These corn milling recommendations will help with meeting target body weights for age and not delay pullet placement because of lagging growth. This was further verified by the greater fleshing of the 600 μm fed pullets at 16 weeks of age. All these parameters indicate proper corn PS is beneficial for preparing pullets for the hen house. Finally, mill performance, efficiency and economics can be optimized by only grinding the 600 μm corn for the first 10 weeks of pullet feeding. Then PS could be enlarged to the 900 μm size without any negative effects on pullet growth or feed intake. Despite the greater mill through put, efficiency and cost to produce 1500 μm corn, it should not be fed to Leghorn pullets because of reduced growth and delayed fleshing the birds will experience.

References are available on request

From the Proceedings of the 6th Mediterranean Poultry Summit