The laying hen produces an average of 150 to 200 g of fresh manure, which is considered a source of pollution due to the high content of nitrogen and phosphorus and contains a large amount of moisture.

Proper management of chicken manure can reduce odors and destroy pathogens. The beneficial effect of using manures of different species including birds has been known for some time. Until the end of the 19th century, agriculture mainly depended on manures to obtain good harvests; however, this rapidly changed with the production of chemical fertilizers. With natural gas sources, cheap and abundant for the synthesis of ammonia, chemical fertilizers became so affordable that manure was displaced; but due to current organic, ecological or sustainability trends, organic fertilizers have once again become important1.

Previously, animals were raised free-range, spread over large areas of land, with an immediate and economic incorporation in situ of their manure to the land where they were grazing. Currently, with large production facilities, livestock tends to be centralized in smaller areas. Although this procedure is more efficient from a productive point of view and implies lower costs with a more adequate disease control and prevention, it leads to the accumulation of large quantities of manures which are far from the agricultural fields where they could be used, resulting in unfavorable environmental conditions by contamination related to odors, nitrates, salts, biological, bacteriological and landscape among others.

In Mexico, manure is obtained mainly from cattle, as well as from laying hens, pigs, goats, and others. The quality of manure varies according to its origin; laying hens’ manure is twice as rich in nitrogen and about five times richer in phosphorus than bovine’s one2. Manure can be in semi-solid-semi-liquid state, fresh with little or no dilution of water and, in any of these forms, can be applied directly to agricultural land, improving or degrading soil fertility if not properly handled. Stacking of manure outdoors until its application, which in Mexico usually happens once a year, causes loss of nutrients by the action of the sun, rain and wind, originating serious environmental contamination problems and damage to the local inhabitants3.

In Mexico, in 1920 there was a waste of manure of 50% due to poor management and application according to the livestock census. Currently, around 49 million tons of manure per year are obtained from animal farming. Manure degradation and stabilization occur spontaneously in nature with the participation of organisms present in soil, which take their energy and food from it.

In this context an adequate waste management was completed, covering an experimental area with layer farming for the supply of the Poultry Center of UNAM, and concerning a flock of 1,600 laying hens. Birds produced an average of 240kg-320kg of fresh feces per day; the goal was to reduce it less 50% in volume with proper waste handling manure, thus decreasing odors, propagation of pathogens and noxious fauna. Laying hens manure was supposed to fertilize fields, if correctly handled, producing a fertilizer rich in nutrients for the soils to the benefit of producers and final consumers.

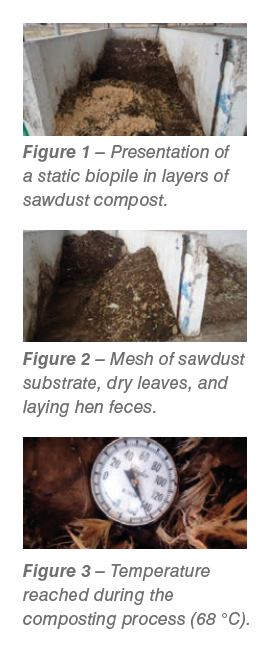

For a correct handling of waste, the most important factor is to have a roofed fenced area with wide doors if the process is completed in an open place. This way nitrogen and phosphorus can be reduced, a key factor for the development of the product used for fertilization. Using 8 containers of 6m³ each, carbon sources or substrate are obtained with leaf litter made by wood chips, sawdust, straw and the excreta, starting with a bed substrate of 20 cm and adding 10 cm of chicken manure, and repeating until reaching the height of less than one meter and above 80 cm (4 layers – Figure 1). Layers can be made by mixing the materials trying not to exceed the m³ (Figure 2). Between day two and three the temperature increases until reaching 70 °C (Figure 3); pathogens can be eliminated at this temperature and then the biopile is formed. If the turning process is carried out two or three times a month, this has the advantage of accelerating the microbiological process; the fermentation process lasts between 30 and 40 days thanks to aerobic and anaerobic composting; at the end of this period one should only wait for the biopile to mature in 3 and 4 months and then it can be used as a fertilizer.

References

- Bourlang N.E. y Enkerlin 1997, Cruz M. S. 1976 y 1986.

- Fernández, 1982.

- Cruz, 1976 and Cruz, 1986.

From the Proceedings of the 68th WPDC