Achieving proper bodyweight, flock uniformity, and sexual maturity at light stimulation are some of the biggest management challenges for broiler breeder farms.

Today’s breeder pullets are growing faster with 6% less feed than 20 years ago. Feed management is a greater challenge today due to fast feed consumption, a result of selecting for appetite traits and reduced feed amounts for a more efficient feed conversion. Feeding pullets during rearing, above all other management factors, is crucial to ensure the birds consistently gain weight and achieve good uniformity to obtain high lifetime productivity with proper health and welfare.

Typically, broiler breeders are given daily feed allotments. Feed management requires consistent monitoring and managing. To ensure feeding is done correctly, observation during feeding time becomes very important. Monitor if birds have fair competition and are receiving equal feed portions. Feed time observations can identify management issues, which can be corrected before they become bigger problems.

There are several essential factors to observe when visiting the breeder house during feeding.

1. Bird behavior during feed presentation

How the farm crew manages feed presentation and trains the flock can explain flock feeding behavior. Flock behavior observation should begin 3 to 5 minutes before the feeding system begins. This will allow enough time to compare the before and after reactions of the flock.

Ideally, the flock should develop a conditioned response by pairing feed time with a signal. As an example, a signal light at the end of the house or sound from feeder equipment can be used to indicate feeding time. Any light or human activity should be prevented before feeding time, as it could trigger the flock’s response. Triggering the flock with human activity or light will create flock agitation and confusion and frustrate access to feeders, which could cause long-term behavioral issues and physical injury during the production period.

2. Feed distribution

Feed distribution should be in the dark with the first loop completed within 3 minutes, followed by turning on the lights. This process will allow birds to spread calmly with sufficient access to the feeder. It is recommended that the second loop of a chain feeder system be activated after the lights are on. This helps level the feed in the track across all hoppers.

Distributing evenly in all feeders allows the flock equal access to feed. For chain feeders, the feed slide of all hoppers must be adjusted at an equal width to allow the same level of feed in the track. For pan feeders, there should be a suitable ring adjustment number. Use the same number for all pans to complete the loop and drop the same feed amount. Feed distribution can also be monitored by crop fill assessment after feeding.

3. Feed space

Increasing flock density compromises feed space. Inadequate feed space causes problems with feed access, creating frustration. On the other hand, too much feed space causes an insufficient feed amount for the system to operate correctly and creates uneven feed distribution. Both scenarios will cause poor weight gain, flock variability, stressed conditions, and undesirable behaviors like feather or vent pecking.

Beginning at placement, a progressive feed space plan can be used to obtain good feed and flock distribution, as well as to configure the system for the correct number of birds per pan or chain length based on age.

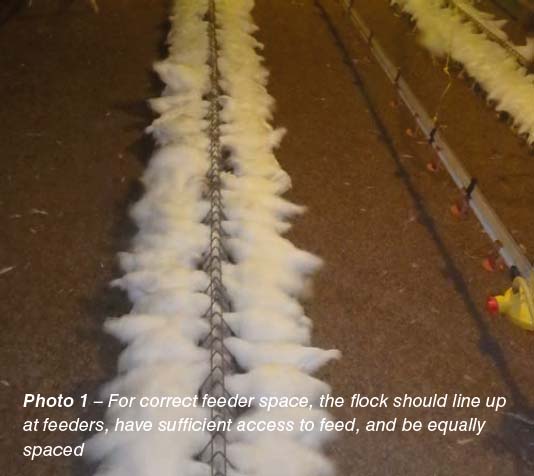

The flock should line up at feeders, have sufficient access to feed, and be equally spaced (Photo 1). Common malpractices include incorrect feeder space or birds drifting between pens after grading. To ensure proper feeder space in different pens after grading or moving birds, feeding time observation remains critical. For progressive feed space recommendations, please refer to the Cobb breeder management guide.

4. Feed cleanup time

Feed intake time, or feed cleanup time, are key considerations in both the rearing and production periods. In the rearing period, pullets will start rapidly cleaning up the feed during the controlled growth phase. Allowing a feed cleanup time of about 40 to 60 minutes from 10 weeks of age until light stimulation is optimal. This provides enough time for equal access to feed. If cleanup time is less than 35 minutes, increase feed volume and prolong cleanup time by applying a feed restriction program. In the production period, hen cleanup time is one of the indicators used to determine the first feed decrease after peak production.

In some cases, feed distribution may be observed, but personnel then proceed to the next house before feed cleanup is complete. This commonly occurs in breeders because they have a long cleanup time. If personnel leave before cleanup is complete, they should return to make sure the flock finish their feed and check drinker functionality.

One of key dictators of cleanup time is feed pellet size. In rearing and production, we recommend a crumble to prolong feed consumption time. Some operators may use mash coarse feed, which increases consumption time compared to a crumble. We discourage using pelleted feed in rearing or production since it can be consumed quickly and there may not be enough volume to guarantee equal distribution.

5. Equipment operations

Maintaining the feeder system correctly prevents equipment failure during feeding time. A regular maintenance program ensures the feeder system is in good condition each day.

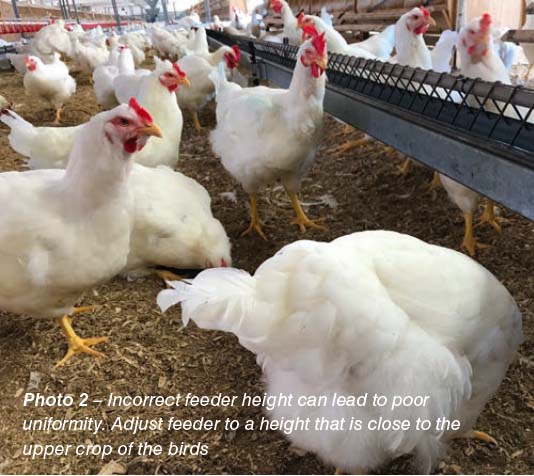

As breeder pullets grow, the feeder height should be increased until frame development is complete at around 12 weeks of age. Incorrect feeder height can lead to poor uniformity (Photo 2). We suggest adjusting feeder height close to the upper crop. In the production period, however, the male feeder line should be maintained at a height where all males can access the pan feeders without female interference.

6. Water consumption

Water is the most essential nutrient for birds. Normally, birds will consume water for 2 to 3 hours after eating. Observation during feeding time can be used to check the water system to see that it provides sufficient volume and correct pressure, especially after feeding. If water is not being consumed after feeding, it is possible that the water lines are restricted or not functioning correctly. Crop palpation 3 to 4 hours after feeding time can be an indicator of water intake. Crops should be soft and lumpy, full of a mix of feed and water.

7. Environment management during feed time

Due to selecting for growth rate, modern broiler breeders have a high rate of metabolic heat production and a high efficiency of utilizing energy for growth. This metabolic energy is converted to body heat that is lost to the environment. Create an environment inside the breeder house that allows the flock to remove excess body heat and remain comfortable. Providing good ventilation during feeding time will reduce metabolic heat stress and prevent a decrease in feed intake, reducing mortality. During feeding time, birds panting is an indication of heat stress and should be addressed immediately. If ventilation is maximized but feed intake still appears to be impacted by heat stress, then consider moving feeding to an earlier time to have cooler temperatures.

8. Bird health and wellness

An unhealthy flock will lack appetite, be lethargic and be reluctant to access feeders. These signs can indicate health-related problems in the flock that require immediate investigations.

In the rearing period, feed restriction programs are commonly applied during the controlled growth phase to increase the amount of feed and consumption time. However, if farm crews observe feed choking or intussusception is diagnosed during the transition period to higher feed amounts, adjust the lighting program to let birds drink 30 minutes before feed distribution. If mortality rises, consider adjusting the feed restriction program or try an everyday feeding regime.

For male management, observing eating behaviors during feeding and checking fleshing scores are the most practical ways to determine proper conditioning.

Feed management is never constant. It influences bodyweight and uniformity, which needs continued management. These 8 key observation points will help breeder farm teams monitor feed management to achieve breeder performance, catching mismanagement early before leading to possibly greater mistakes.