Why Water Quality and System Management Matter More Than Ever

In modern broiler production, drinking water is often treated as a secondary input compared to feed formulation, genetics, or housing design. Yet water is the most consumed nutrient in poultry production and plays a decisive role in growth performance, welfare, litter quality, and overall flock health.

Suboptimal water quality or poorly managed drinking systems can compromise feed intake, reduce weight gain, increase wet litter and footpad dermatitis, and undermine the effectiveness of vaccination and medication programs. For these reasons, drinking water management should be considered a core component of broiler management rather than a technical detail.

Water Intake and Broiler Performance

Broilers consume significantly more water than feed by weight. Water intake is closely linked to feed intake, and any reduction in water availability or palatability is rapidly reflected in lower feed consumption and growth rate.

Several studies have shown that broilers typically drink between 1.6 and 2.0 grams of water per gram of feed, depending on age, diet composition, and environmental conditions. This ratio highlights the sensitivity of performance to changes in water intake, especially during the first weeks of life, when growth rates are highest and physiological reserves are limited.

Water temperature also plays a role. When drinking water becomes too warm, particularly during hot weather, water intake may decline, exacerbating heat stress and further depressing feed intake.

Drinking System Design and Installation

The design and installation of the drinking system have a direct impact on water availability and hygiene. Poorly installed pipelines, dead ends, sagging drinking lines, or sharp bends can lead to sediment accumulation, airlocks, and uneven water distribution. These conditions increase the risk of bacterial growth and biofilm formation within the system.

Drinking lines should be installed horizontally and adequately supported to prevent sagging over time. Materials used for pipelines and drinking lines should have smooth internal surfaces to reduce the adhesion of organic matter and microorganisms. Consistent water flow throughout the system is essential to ensure that all birds have equal access to water.

Nipple Type, Flow Rate, and Bird Behaviour

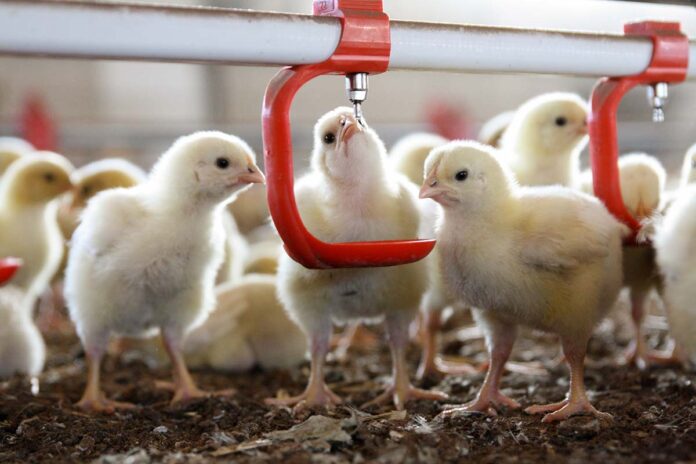

The choice of drinking nipple and flow rate must match the drinking behaviour of broilers. Birds drink by pecking and allowing water to flow into the beak and down the throat; they do not suck water.

Excessively high flow rates can result in spillage, leading to wet litter, increased ammonia emissions, and a higher incidence of footpad lesions. Conversely, flow rates that are too low can limit water intake, especially in fast-growing birds.

Correct adjustment of water pressure and flow rate allows broilers to drink efficiently without excessive water loss. Regular checks along the drinking line help identify blocked or leaking nipples before they affect flock performance.

Water Pressure Management

Maintaining appropriate water pressure is critical for consistent water delivery. Pressure that is too high increases spillage and litter moisture, while pressure that is too low restricts water intake and may reduce growth performance.

Monitoring water pressure at both the beginning and the end of drinking lines provides a more accurate picture of system performance, particularly in long houses. Pressure regulators and gauges allow for fine adjustments according to bird age and body weight, ensuring that water availability remains optimal throughout the production cycle.

Height Adjustment of Drinking Lines

Drinking line height must be adjusted regularly to match bird growth. At placement, nipples should be positioned at eye level so chicks can easily locate water. As birds grow, the lines should be raised gradually so that broilers drink with a slightly extended neck and a straight back.

Failure to adjust line height frequently can lead to either excessive spillage or reduced water intake. Gradual, frequent adjustments are preferable to sudden changes, which may disrupt drinking behaviour and temporarily reduce consumption.

Water Source and Quality Monitoring

Broiler operations rely on different water sources, including mains water, well water, and surface water. Each source carries specific risks related to mineral content, microbial contamination, or seasonal variation in water quality.

Regular water sampling is essential to monitor parameters such as pH, iron, manganese, nitrate levels, and microbial load. Elevated mineral content can promote deposits inside the drinking system, while microbial contamination can directly affect bird health and indirectly support biofilm formation.

Filtration and appropriate water treatment strategies help reduce these risks and contribute to a more stable and predictable water supply.

Biofilm Formation and Its Consequences

Biofilm is a complex layer of microorganisms embedded in a protective matrix that adheres to the inner surfaces of drinking lines. Once established, biofilm is difficult to remove and can continuously contaminate the water delivered to birds.

Biofilm can interfere with the effectiveness of vaccines and medications administered via drinking water and may act as a reservoir for pathogenic bacteria. Warm temperatures, low flow rates, and the presence of organic residues all promote biofilm development.

Preventive measures include regular flushing of drinking lines, thorough cleaning between production cycles, and routine monitoring of water quality at the point of use, not only at the source.

Integrating Water Management into Broiler Production Strategy

Effective drinking water management requires a holistic approach that combines system design, daily management, and regular monitoring. While water infrastructure represents a relatively small proportion of total investment in a broiler house, its impact on performance, welfare, and economic outcomes is substantial.

Treating water management as a strategic component of broiler production rather than a technical afterthought helps reduce avoidable losses and supports more consistent production results.