In recent years, pulsed ultraviolet light has been shown to reduce microbial pathogens on the surface of shell eggs, crucial for maintaining good chick health.

J.R. Cassar, L.M. Bright, E.W. Mills, A. Demirci, P.H. Patterson – The Pennsylvania State University

In the United States, annually an average of 287.1 eggs are consumed per person and over 14.1 billion eggs are set in hatchery incubators to produce chicks destined for the meat and egg industries. Reducing the microbial load on eggs is crucial for reducing food-borne associated outbreaks and maintaining good chick health.

Pulsed ultraviolet (PUV) light is an emerging antimicrobial intervention that is non-ionizing, non-thermal (in short duration), non-chemical, and non-aqueous. Pulsed ultraviolet light systems deliver energy-intense broad spectrum (100-1100 nm) pulses generated by a xenon flashlamp. Mechanisms of microbial inactivation of PUV light are attribute to photochemical (formation of thymine dimers), photophysical (microvibrations), and photothermal (localized heating). In recent years, PUV light has been shown to reduce microbial pathogens on the surface of shell eggs using a static PUV light unit.

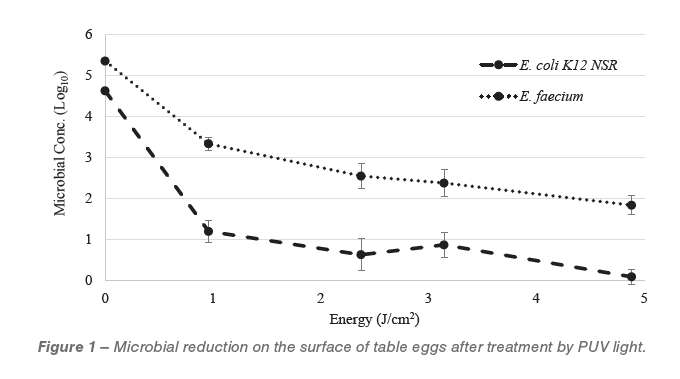

In this most current study, shell eggs were surface inoculated with Escherichia coli or Enterococcus faecium prior to PUV light treatment. Eggs were processed using a modified egg candling conveyor that provided complete rotation of eggs under a PUV light flashlamp. Pulsed UV light treatment achieved complete inactivation of both microbial strains, with greater energy resulting in a greater germicidal response (P<0.05). Treatments of 1.0, 2.4, 3.1, and 4.9 J/cm² resulted in of 3.83, 4.26, 4.28 and 4.62 Log10 CFU/cm2 for E. coli and 2.04, 3.12, 3.11 and 3.82 Log10 CFU/cm2 for E. faecium, respectively.

Additionally, this study evaluated the effects of PUV light processing of hatching eggs on both embryo and chick growth parameters. Using the aforementioned system, 4 replicates of 125 fertile eggs per rep were treated with 0 (control), 4.9, 24.4 or 48.8 J/cm² of PUV light. Following processing, eggs were incubating under normal commercial incubation conditions. There was no significant effect of the PUV light treatment on percent fertility, hatchability, or hatch (P>0.05). Also, there were no significant effects on post-hatch observations, including livability, average bird weight at hatch or at 42 days of age (P>0.05).

In addition to its potential as an antimicrobial intervention for the egg industry, pulsed ultraviolet light has been evaluated for decontamination of number of applications in the poultry industry including chicken, chicken-based pet food, and food conveyor surfaces.

Pulsed ultraviolet light processing of the surface of whole chicken parts and pet food achieved a modest 1.0 Log10 reduction of E. coli K12 after 30 and 70 J/cm2 fluence treatments. Pulsed ultraviolet light applied as a sterilizing process for food conveyor materials achieved microbial reductions ranging from greater than 2.0 Log10 to complete inactivation (>4.0 Log10) of E. coli K12 and lactic acid bacteria after 3.33 J/cm2 fluence treatments.

In conclusion, it is evident that the effectiveness of PUV light as an antimicrobial intervention is dependent the complexity of the surface matrix, the total treatment fluence, microbe type, and numerous other parameters. Future research should focus on optimizing PUV light processing for sterilization of eggs and other comparatively simple surfaces such as conveyor materials. Additionally, a formal cost analysis should be conducted to justify implementation of PUV light as an antimicrobial intervention for both hatching and table eggs.

From the Proceedings of the Midwest Poultry Federation Convention 2021

Cassar, J. R., L. M. Bright, P. H. Patterson, E. W. Mills, and A. Demirci. 2021. The efficacy of pulsed ultraviolet light processing for table and hatching eggs. Poultry science, 100(3), 100923. dio: 10.1016/j.psj.2020.12.021.