The effect of feed form is well established, however, feed physical quality is often seen as an issue in the field (see Figure 1). Several evaluations were conducted in Aviagen Turkey’s (ATL) facilities in the UK to assess the impact of feed physical quality on modern genotypes by assessing both crumb and pellet quality on commercial turkey performance.

Evaluation

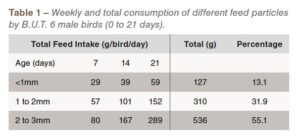

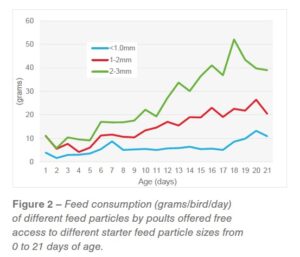

The first evaluation assessed the impact of crumb particle size on feed intake in turkey poults from 0 to 3 weeks of age. A standard crumbled starter diet was sieved into three different particle sizes; small (<1mm), medium (1 to 2mm) and large (>3mm) and provided free choice to male B.U.T. 6 poults. Feed consumption of each feed particle size was measured daily during the entire period of the trial. The feed consumption data (see Figure 2) shows poults have a clear preference for medium and larger particle sizes with much lower preference for smaller particles (<1mm). This trend was quite consistent through the entire period from 0 to 21 days of age. The proportion of each particle size consumed was measured for each period and total consumption assessed over the entire period (see Table 1). The study did not include assessment of feed particles larger than 3mm, however the overall trend shows poults have a consistent preference for larger particle sizes with much lower preference for smaller particles. This trend was quite consistent through the entire period with a tendency towards preference for larger particles with increasing age.

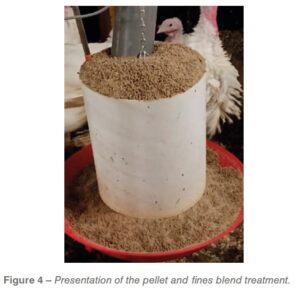

A small-scale evaluation examining the effect of different feed forms was conducted in ATL facilities in the UK. This involved feeding  B.U.T. 6 males ‘good’ and ‘poor’ quality crumbs and pellets from 0 to 20 weeks. Diets were prepared according to the ATL recommended nutrient specifications and feeding programme. The starter diet was provided as a sieved crumb for the ‘good’ feed physical quality control and an unsieved crumb for the ‘poor’ feed physical treatment. The ‘poor’ pellet quality treatment was prepared by hammer grinding pellets to a fine consistency (fines) and then blended with intact pellets to result in a 50:50 mix of pellets and fines (see Figure 3).

B.U.T. 6 males ‘good’ and ‘poor’ quality crumbs and pellets from 0 to 20 weeks. Diets were prepared according to the ATL recommended nutrient specifications and feeding programme. The starter diet was provided as a sieved crumb for the ‘good’ feed physical quality control and an unsieved crumb for the ‘poor’ feed physical treatment. The ‘poor’ pellet quality treatment was prepared by hammer grinding pellets to a fine consistency (fines) and then blended with intact pellets to result in a 50:50 mix of pellets and fines (see Figure 3).

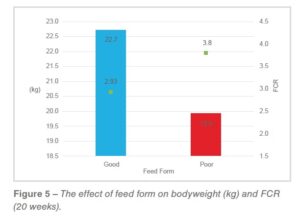

The mix of fines and pellets resulted in a feed physical quality similar to poor feed physical quality which can sometimes be seen in the field (see Figure 4). The results showed there was a significant depression in bodyweights to 20 weeks of age; the poor treatment resulted in a 12.3% reduction in bodyweight loss relative to the control. FCR deteriorated by 36% in the poor treatment relative to the control at 20 weeks of age (see Figure 5).

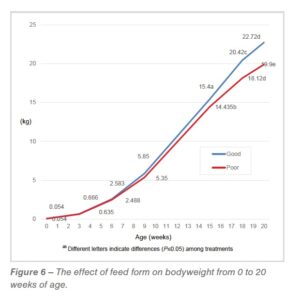

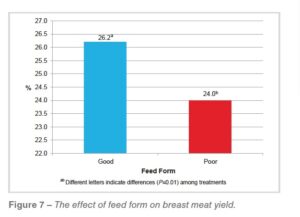

The negative effect of poor feed form on bodyweight was evident through the lifetime of the birds. This effect was detected as early as 3 weeks of age and continued, with increasing effect, to the end of the trial period (see Figure 6). Breast meat yield was assessed at 20 weeks of age, the poor treatment reduced breast meat yield by 8.4% (see Figure 7). This effect on breast meat yield is most likely related to the effect of feed form on physiological development to this age i.e. the birds fed the poor feed form were physiologically less developed at 20 weeks of age compared to the birds fed the control, hence breast meat was not as well developed. The effect of feed form on performance was much greater than previously observed; in particular the magnitude of effect on FCR was unexpected. The data suggests that those birds fed the poor feed form ate significantly more feed than birds fed the control diet but did not convert this feed to liveweight. Feed wastage is often evident when birds are fed poor quality pellets. While feed wastage was evident in some pens, this was superficial and not enough to account for the degree of difference in FCR. Another possible explanation for the degree of effect on FCR may be related to the preparation of the ‘poor’ feed treatment. The degree of fine material within the poor feed treatment was very significant and also the extent of pulverisation during the feed grinding process may have resulted in a more extreme ‘poor’ feed form than assessed in some other trials which compared pellets to mash diets. Nonetheless, the poor treatment was representative of poor feed form in the field and the results reinforce the importance of ensuring feed physical quality is optimal and is adequately assessed within the organisation.

The negative effect of poor feed form on bodyweight was evident through the lifetime of the birds. This effect was detected as early as 3 weeks of age and continued, with increasing effect, to the end of the trial period (see Figure 6). Breast meat yield was assessed at 20 weeks of age, the poor treatment reduced breast meat yield by 8.4% (see Figure 7). This effect on breast meat yield is most likely related to the effect of feed form on physiological development to this age i.e. the birds fed the poor feed form were physiologically less developed at 20 weeks of age compared to the birds fed the control, hence breast meat was not as well developed. The effect of feed form on performance was much greater than previously observed; in particular the magnitude of effect on FCR was unexpected. The data suggests that those birds fed the poor feed form ate significantly more feed than birds fed the control diet but did not convert this feed to liveweight. Feed wastage is often evident when birds are fed poor quality pellets. While feed wastage was evident in some pens, this was superficial and not enough to account for the degree of difference in FCR. Another possible explanation for the degree of effect on FCR may be related to the preparation of the ‘poor’ feed treatment. The degree of fine material within the poor feed treatment was very significant and also the extent of pulverisation during the feed grinding process may have resulted in a more extreme ‘poor’ feed form than assessed in some other trials which compared pellets to mash diets. Nonetheless, the poor treatment was representative of poor feed form in the field and the results reinforce the importance of ensuring feed physical quality is optimal and is adequately assessed within the organisation.

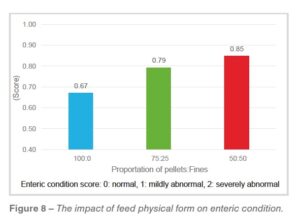

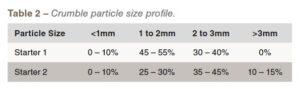

Further evaluations assessed the impact of feed form on enteric condition; birds fed poor feed physical quality from day old to 12 weeks of age had poorer enteric condition (see Figure 8) and also experienced increased incidence of gut leakage relative to those fed good quality crumbs and intact pellets. This effect was also detected in much older birds; 18-week-old birds fed with a poor feed physical quality feed for a shorter period of time (one and a half weeks) also had poorer enteric condition relative to those fed intact pellets. These results demonstrate the impact of feed physical quality is relevant at an enteric level and not just from a farm or processing point of view. Assessment of feed physical quality is usually measured by a sieving assessment of crumbs and a pellet durability index (PDI). The target particle size profile for starter diets in a crumb form are as follows in Table 2. Pelleted products must contain a minimised quantity of fines particles (<1mm), aiming for less than 10% fines (farm sample assessment) with the remainder as intact pellets.

Further evaluations assessed the impact of feed form on enteric condition; birds fed poor feed physical quality from day old to 12 weeks of age had poorer enteric condition (see Figure 8) and also experienced increased incidence of gut leakage relative to those fed good quality crumbs and intact pellets. This effect was also detected in much older birds; 18-week-old birds fed with a poor feed physical quality feed for a shorter period of time (one and a half weeks) also had poorer enteric condition relative to those fed intact pellets. These results demonstrate the impact of feed physical quality is relevant at an enteric level and not just from a farm or processing point of view. Assessment of feed physical quality is usually measured by a sieving assessment of crumbs and a pellet durability index (PDI). The target particle size profile for starter diets in a crumb form are as follows in Table 2. Pelleted products must contain a minimised quantity of fines particles (<1mm), aiming for less than 10% fines (farm sample assessment) with the remainder as intact pellets.

Pellet durability assessments are normally made at the mill laboratory via specialised devices such as a Holmen Tester or Tumbling Tester (see Figure 9), a durability of >90% is realistic for most pelleted feeds.

These assessments involve placing a sample of feed through an aggressive process which is aimed at replicating the physical insults to the pellet in the field. This assessment allows the mill to know whether manufactured feeds meet physical quality standards. Assessment of feed physical quality should not just be conducted at the mill, farm assessments give a good indication as to what is provided to the bird especially if the sample is taken directly from the feed pan. This can be conducted via the use of a hand sieving device (see Figure ten); the procedure is straightforward and practical for most farms to conduct. For more information on the use of the hand sieve, please contact turkeysltd@aviagen.com.

These assessments involve placing a sample of feed through an aggressive process which is aimed at replicating the physical insults to the pellet in the field. This assessment allows the mill to know whether manufactured feeds meet physical quality standards. Assessment of feed physical quality should not just be conducted at the mill, farm assessments give a good indication as to what is provided to the bird especially if the sample is taken directly from the feed pan. This can be conducted via the use of a hand sieving device (see Figure ten); the procedure is straightforward and practical for most farms to conduct. For more information on the use of the hand sieve, please contact turkeysltd@aviagen.com.

There are many courses of action which the mill can take to improve poor feed physical quality. Behnke (1996) quantified the effect of different feed manufacturing processes on pellet durability, the main areas identified were grinding, conditioning and pelletizing processes changes in the formulation can also have an effect for example even 5% addition of wheat-based materials can improve pellet durability very significantly. The key point is that poor feed physical quality is not acceptable and there are means to improve feed physical quality.

There are many courses of action which the mill can take to improve poor feed physical quality. Behnke (1996) quantified the effect of different feed manufacturing processes on pellet durability, the main areas identified were grinding, conditioning and pelletizing processes changes in the formulation can also have an effect for example even 5% addition of wheat-based materials can improve pellet durability very significantly. The key point is that poor feed physical quality is not acceptable and there are means to improve feed physical quality.

Summary

• Feed physical quality has a significant impact on Turkish performance, perhaps significantly more than previously determined.

• Optimizing feed physical quality not only supports farm performance but also improves processing yield.

• Communication of feed physical quality standards between the farm and the mill is vital to ensure that the needs of the modern bird are understood and are met.

• There are several approaches to improving feed physical quality within the mill some of which do not involve significant investment.

• Monitoring of feed physical quality in the mill and also on the farm is vital to ensure that feed form is continuously meeting standard.

References

Behnke, K.C. 1996. Feed manufacturing technology: current issues and challenges. Animal Feed Science and Technology, Vol. 62, pp. 49-57.

Brewer, D.E. and P.R. Ferket. 1989. The effect of pellet integrity and lignosulfate on performance of growing toms. Poultry Sci. 68:18.

Nixey, C. 1994. Feed intake is the key to growth rate in turkeys. Feed Mix 2:19-21.