The demand for poultry meat will increase because of population growth and changing socio- economic factors. Resources will become constrained and changing consumer perceptions will result in pressure to produce poultry meat in a sustainable manner. Sustainability is a multi-faceted concept and it is not feasible to select only those aspects that suit a particular narrative.

We should focus on improving poultry nutrient utilization, making optimum use of the ingredients at hand, and rethinking our various approaches to feed specifications. Although our decision making will be reinforced by enhanced data resources, these will not replace the nutritionist as the ultimate decision maker.

Energy

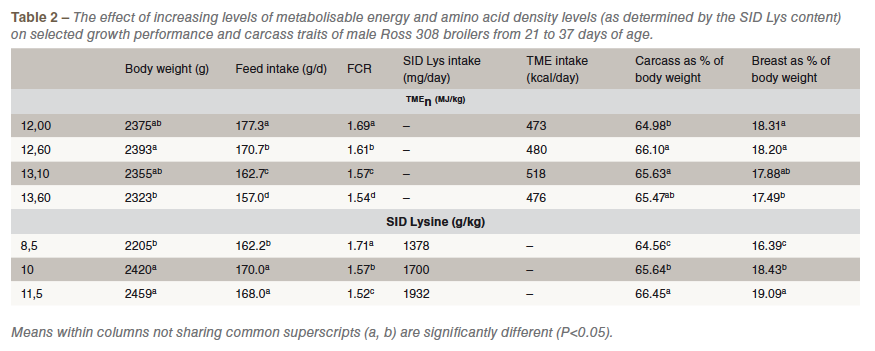

It is unlikely that the efficiency of energy utilization for absolute growth will change, but the sooner a bird reaches target weight, the smaller the proportion of energy used for maintenance purposes will be. Our role as nutritionists is to meet poultry demand for sufficient calories on each day of the production cycle. As can be seen from Table 2, the broiler has the ability to maintain its energy intake regardless of the energy level of the diet. In commercial situations, however, it is not this simple since the pressure created by high stocking densities and limited feeding space prevents poultry from consuming enough feed to meet their energy demands. As a rule, energy intake increases as dietary energy levels rise, with a concomitant increase in field performance. It may not be possible to reduce the energy requirement of the bird, but it is possible to feed diets of different nutrient density in order to utilise cheap ingredients and maximise financial returns. Care should be taken not to focus on producing meat at least cost; rather, we should concentrate on maximising returns (profit).

The real challenge is to calculate energy balance in the broiler. To achieve this, an energy system is required, both to equitably quantify one ingredient relative to another and to enumerate the bird’s requirements. In theory, the values determined should be linear and additive. Any system should be straightforward, cost-effective and repeatable across laboratories. Parsons (in 2011) believes that the metabolisable energy (ME) system will be the primary and preferred measurement of energy in the foreseeable future; indeed, most commercial feed is formulated on this basis. Mateos (et al., in 2018) laments that despite abundant research, no simple procedure exists to evaluate the energy content of ingredients and diets.

Choct (in 2017) argues strongly that the use of ME is limiting and that any efforts spent on a workable net energy (NE) system are justified. NE gives a closer representation of ‘true’ or usable energy, but it does have various shortcomings. It is complicated, time-consuming, expensive to analyze and, as yet, it has no standardized method. In addition, NE systems apply equations that utilise ME as a starting point. Thus, any errors in the ‘base’ ME values are automatically carried over. NE systems mostly use CP as a measure to calculate the expected heat increment (HI) of a diet. Not all N in the diets is amino nitrogen so perhaps this is an over- simplification. In addition, crystalline amino acids are high in nitrogen and therefore high in crude protein, but they have a close to zero HI in digestion since they are already in their basic form. This is relevant in modern poultry diets where the use of synthetic, crystalline amino acids is increasing. The NE system, as with all systems, fails to account for the non-linearity of fat and fibre addition to poultry diets.

Of interest, is the use of near-infrared spectroscopy (NIRS) technology to predict the chemical composition of an ingredient and hence to predict ME indirectly or, more interestingly, to directly predict AMEn. The advantages of NIRS are that it is fast, cheap to run and gives repeatable results. Its limitation is that it is only as good as the calibration used in its set up. In addition, if a flawed energy system is used to calibrate the machine, this will be carried across to all results.

The nutritionist is required to decide which energy values to use when formulating, and slavish adherence to a single source of information can be problematic. The perfect energy system does not exist. This may be because the energy content of a diet is not a property of the diet itself, but rather a property of the bird consuming that diet. However, even if a system is not perfect, it only has to be better than the approach it supersedes. We should accept the flaws of the ME system while we strive for something better, a standardized NE system.

Minerals

Minerals comprise a small proportion of the diet, but their importance to the birds cannot be overlooked. Dietary supplementation with high levels of inorganic trace minerals is expensive and may be harmful to the environment. Organic minerals are compounds in which minerals are covalently complexed with organic ligands. They are less reactive than mineral salts but can be supplemented at lower concentrations than sulphates and oxides without impacting on bird performance. Currently, organic minerals are an expensive option but, in future, their use will increase. Phosphorus (P) and calcium (Ca), deserve special attention. Not only are the global supplies of P constrained, but the way in which P is managed in poultry diets is a key component of sustainability from an environmental perspective. Nutritional strategies can improve the effective use of P, to avoid overfeeding and minimize P excretion. Current research would indicate that the P requirements of poultry are lower than mostly used in practice, and the use of phytase allows levels to be reduced still further.

These findings are in stark contrast to the recommendations of the primary breeding company and to general commercial practice. New recommendations have been published by INRA. Although these recommendations differ from each other, they are consistent in that they recommend low levels of both minerals in grower and finisher diets. Phytase doses will likely increase, resulting in more complete degradation of the phytate plant material.

Implementation of these strategies will lead to reduction in demand for P and will also decrease the polluting levels of P in poultry manure. Our current approach when formulating poultry diets is to use some measure of available P and the total Ca. Clearly, we would do a better job of formulation if we were to use a measure of available Ca, and then formulate accordingly.

Discussion

As clichéd as the term ‘precision nutrition’ is, it is the goal that nutritionists strive for. If we are able to meet the nutrient requirement of each individual in a poultry flock, on each day of the production cycle, we will enhance our ability to produce poultry meat in a sustainable manner. Bear in mind that well-performing poultry flocks will have different requirements to poorer poultry flocks. This is challenging when most operations use only three or four phases of feed throughout the broiler cycle. In order to achieve the lofty ambition of precision nutrition, ingredients will need to be quantified more accurately than they are at present.

Formulating diets by using a single value for energy ignores the fact that we are unsure of how to measure energy or to cope with variability in the first place. The non-linear nature of fat and fibre addition to bird diets will need to be accommodated.

The efforts made by nutritionists will need to be matched by improvements in feed manufacture. Some form of real-time energy determination and formulation adjustment would be helpful. Disparate parcels of ingredients will need to be identified and preserved, before being precision weighed and mixed. These suggestions will bring about an unimaginable level of management complexity and cost in terms of ingredient purchasing, storage management and logistics. On farms, the bulk of management resources are likely to be utilised in deciding which diet to feed to which flock.

Clearly a more pragmatic approach will be required. Nutritionists will have to make considered decisions about ingredient energy and nutrient content. Decisions about feed specifications will also need to be made, bearing in mind sustainability, the cost and availability of ingredients, farm management, the end products and, importantly, net returns.

Feeding programmes will have to be designed to ensure that bird requirements are met, while minimising harmful pollutants. These programmes will have to match the logistics of specific farms, as determined by feed bin size, delivery vehicle capacity and bird numbers. Feed millers will need to manage their ingredients more adroitly, for example by using multiple bins for key ingredients, but probably not by changing formulations on an hourly basis.

The feeding and nutrition of meat chickens have never been more complex, and the advances are going to continue. Rather than expecting computer systems to make our lives easier, professionals in the broiler industry will be required to make more decisions than ever before. Although we are a long way from the goal of precision feeding, the use of the information already at our disposal will ensure that the broiler industry moves towards sustainability in every aspect.

References are available on request

From the Proceedings of the 2019 Australian Poultry Science Symposium