Consumers worldwide start to worry about the use of antibiotics in livestock production and their effect on human health. Antibiotic-free chicken is increasingly becoming the standard for supermarkets and restaurants. To produce poultry without using antibiotics, poultry farmers have to pay more attention to hygiene and the health of the broilers. Water hygiene is an important part of this.

Reducing the use of antibiotics

The fear of resistance has prompted an increasing number of countries to ban the use of antibiotics in livestock production. This means that many poultry farmers have to manage their poultry in a different way. The main point is to improve hygiene in and around the poultry houses. After the supply of healthy day-old chicks, it is the task of the poultry farmer to keep them healthy.

All possible ways in which pathogens can enter the house should be monitored. Potential factors include water, feed, vermin, personnel and farm equipment. Without antibiotics, there is no last line of defence, so pathogens must be stopped before they reach the animals. Improving overall hygiene is an important part of this. This also applies to the drinking water system.

Improving water quality

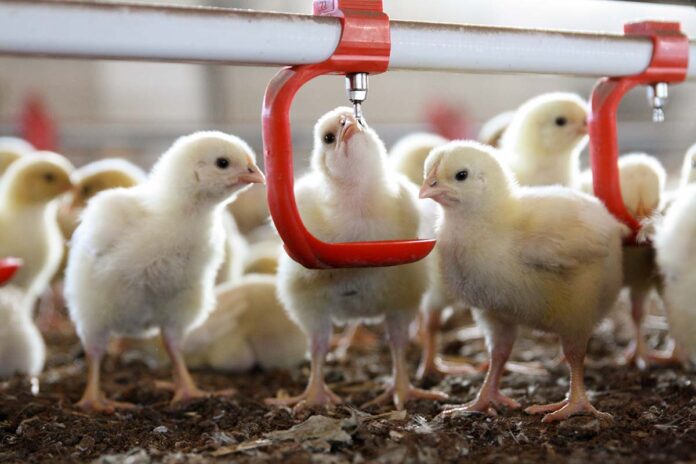

Generally broilers consume 1.6 to 2 times more water per day than feed. When that water is polluted, the couple will perform less and suffer from gut health problems.

With the introduction of drinking nipple systems to replace open water systems, the quality of drinking water has improved considerably. Yet modern drinking systems only have added value if the lines are kept clean and the water does not contain any harmful bacteria. The main danger here is that biofilm can form on the inside of the pipework. This biofilm acts as a food source for harmful organisms that can be spread through the water.

To maintain the water quality, poultry farmers must use effective disinfectants to keep the drinking lines free of biofilm. In an antibiotic-free production, it is important to regularly check the quality of the original water sources and to carefully clean the lines and drinking equipment between rounds. These cleaning procedures can be quite time consuming, but using an automatic flushing system will make it much easier.

What is an automatic flushing system?

An automatic flushing system consists of a flushing computer, pressure regulator, end air outlet set and sensors. The flushing computer regulates the entire flushing process by processing the information obtained from various sensors. These settings can be personalized in the following ways:

- The duration of the flushing program

- Calculating and programming the amount of water used

- Interruption of the flushing program when administering medication

- The possibility to flush per line, all lines or automatically

How does this work?

Sensors in the drinking lines register the quality and temperature of the water in the lines, to which the computer then responds. A biofilm sensor registers the cloudiness of the water by means of light measurement. The colour of the light indicates the level of pollution. When the set parameters are exceeded, the lines are automatically flushed.

The same happens when the temperature sensor indicates that the programmed maximum water temperature has been reached. It is also possible to install a second sensor in the supply line. If the temperature difference between this sensor and the sensor in the drinking lines is too high, the lines are automatically flushed.

If the cloudiness of the water does not dissolve or the water temperature remains higher than allowed, it may happen that the pre-programmed maximum number of flushing rounds is reached. When this number is exceeded, the computer issues an alarm indicating that additional measures are required.

Quality and hygiene

The quality of the drinking water is extremely important for the health of a broiler. The use of an automatic flushing system contributes to improving hygiene and thus the reduction of antibiotics.