AZA INTERNATIONAL was founded towards the end of the 1950′s and established itself as the leader in the production of automatic conveying systems for animal feed. Thanks to a dynamic enterprise vision, always centered around the ever-changing needs of the market, the company is once again ready to launch in 2016 a brand new line of extremely innovative products designed for the aviculture sector. The main innovations concern broilers and turkeys with the launch of MIXTA feed pan, while the new linear trough feeder BREEDAZA and SELF-DOSY feed pan have been designed for layers and breeders, respectively.

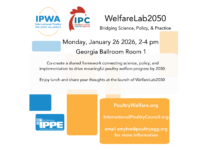

The new feed pan manufactured for turkeys is also suitable for a multipurpose use involving turkeys, broilers and ducks. The well-tested “window system” allows this feed pan to automatically dose the quantity of feed to supply, which can also be adjusted if necessary by choosing between 6 different levels. Cleaning operations are fast and easy. The bottom pan opens in 1 second allowing the washing of all the internal components of the feed pan. The optimal pan height allows the chick to easily access the feed from the first day of life while preventing it from stepping inside the pan. The anti-waste ring used for transitioning from the first phase to the second is easily assembled/disassembled without the need of screws or tools, and is firmly secured to the pan in order to resist any strike or impact. The upper section of the cone is manufactured with a flexible material, which enables the feed pan to endure any impact caused by the birds whilst not hurting them.

MIXTA is equipped with a sliding closer and it is available for conveying tubes of 38, 45 and 48 mm. It can be easily fixed to and released from the conveying pipe.

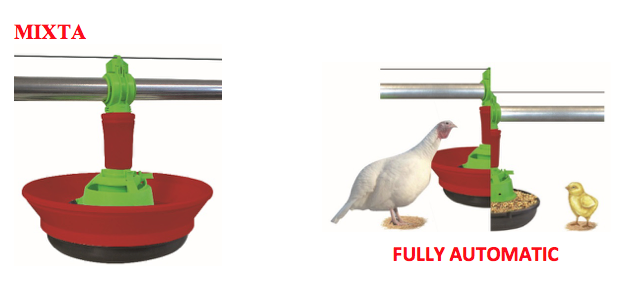

The new feed pan manufactured for cocks, sturdy and easy to manage.

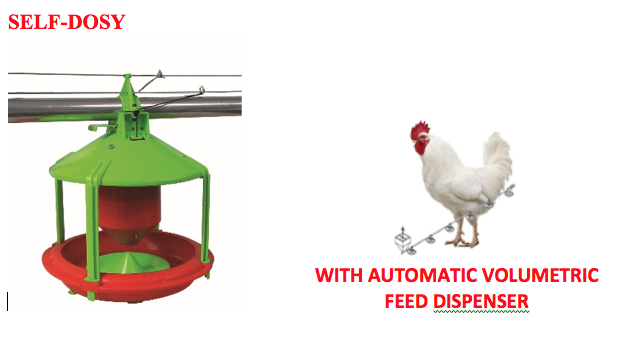

SELF-DOSY feed pan features an inbuilt volumetric feed dispenser with a centralized adjustment device that allows to precisely change the quantity of feed to be supplied by all the feed pans accordingly to the different growth phases during flock life. As a result, there is no need for a high speed/capacity conveying system nor for a winching device that lifts the pans from the ground while delivering the feed into the circuit, even the installation of weighted feed systems is not necessary. Every aspect of the feed dosing is managed by the volumetric dispenser of SELF-DOSY and, as it is true for every system that employs volumetric dispensers, the feed distribution happens all at once throughout the whole line.

Specifically designed for strong and aggressive animals, the feed pan is steadily fixed to the conveying pipe in order to provide an equal distribution of feed inside the pan. Every feed pan is equipped with a sliding closer and the bottom pan has a large diameter (40 cm) that also features a special anti-waste rim. Moreover, the bottom pan itself is easy to remove allowing an efficient cleaning of all the inner parts. The feed pan is available for conveying tubes of 38, 45 and 48 mm.

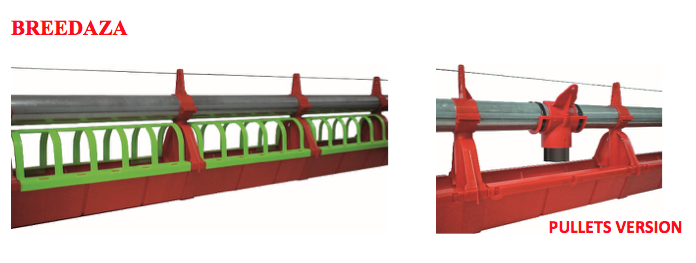

The new linear trough BREEDAZA feeding system is a controlled feed distribution system available in several versions designed for breeders, layers, pullets in cages, free-range bird houses and flocks on the ground. During the past few years, the outstanding performances of this product favored its success over the more traditional systems available on the market. The new version to be launched in 2016 features a trough and a grid entirely made of plastic, easy to assembly, safe and above all resistant. The anti-cock grid can be adjusted in accordance with the size of the specific breed. The pullets’ version of the linear trough system can be used from the first day of life of the chick. BREEDAZA chain and auger system achieves excellent results in feed distribution, being instantaneous and equal in quality and quantity along the entire trough length. The bottom of the linear trough is completely free of obstacles, which grant the animals an easy access to the feed, and allows them to empty out the trough after every meal.

Designed for an easy and swift management, PRATIKA is the groundbreaking and most technologic feed pan for broilers available on the market. This feed pan is fully automatic and provides an ideal feed distribution. The low edge of the bottom pan allows the chicks to reach for the feed with ease from the first day. The feed pan can be opened in 1 second, either manually or by using a centralized device, allowing an easy washing of all the inner components of the feed pan. PRATIKA is also available in a version specifically designed to fit inside cages without any additional hindrance above the conveying pipe.

Designed for an easy and swift management, PRATIKA is the groundbreaking and most technologic feed pan for broilers available on the market. This feed pan is fully automatic and provides an ideal feed distribution. The low edge of the bottom pan allows the chicks to reach for the feed with ease from the first day. The feed pan can be opened in 1 second, either manually or by using a centralized device, allowing an easy washing of all the inner components of the feed pan. PRATIKA is also available in a version specifically designed to fit inside cages without any additional hindrance above the conveying pipe.

This sturdy feed pan is designed for turkeys of any size and age. Available in several versions and suitable for a multipurpose use with turkeys, ducks and broilers. The optimal pan height allows an easy access to the feed from day 1 without letting the chick to step on it. The anti-waste ring for the second phase is quickly assembled with no need for screws or tools, and is firmly secured to the pan against any strike or impact. The adjustment of the feed level can be manual or centralized. Cleaning operations are fast and the inner components of the feed pan are easily washable, in addition, MODULA feed pan can be auto-locked in a cleaning position by rotating it around the pipe for 90°, a position in which the entire feed pan takes up space in height for only 20 cm. Besides these new products, AZA INTERNATIONAL can count among its range and additional line of feed pans for the aviculture sector. For example, the successful DUO system for broilers or the series of feed pans for breeders and layers EXACTA and FLEXA TWR. The AZA INTERNATIONAL products are the best choice in modern poultry farming, since their quality is guaranteed made in Italy and their prices are competitive.

AZA International S.r.l.

Via Roma 29

24030 Medolago (Bergamo) Italy

Phone (+39) 035-901240

Fax (+39) – 035 – 902757 – 4948241

Email: info@azainternational.it

http://www.azainternational.it