Among various technologies for sustainability in animal production, anaerobic digestion or biogas technology is recognized for its multiple functions and benefits. It breaks down organic wastes, produces biogas energy, captures and reduces green house gases (GHG) emission, reduces odors, controls pathogens, sanitizes the farm environment, recycles nutrients for organic fertilizer and generates value added co-products.

Because of the history of development and recent improvement, the technology is maturing and its market emerging, especially in China and European countries (Shih, 2012, 2015). The interest in the U.S. is also on the rise (USDA- EPA- DOE, 2014). On the other hand, two major issues still remain that hamper commercial development. First, the commonly used large-scale digester systems are expensive in construction and complex in operation. Typically, it is not affordable by farmers without government subsidy. Second, the large amount of daily effluent from the digester, or digestate, is hard to manage for utilization or discharge. With forty years of research and experience in the field, this author has recently developed a new system called Holistic Digester™ for animal waste. It is simple to build, easy to operate, adaptable for large and small animal farms to claim all benefits of anaerobic digestion for sustainability. In the long run, it will enable and enhance the sustainability of our animal and agricultural production, environment and green energy.

Reducing GHG emission

On December 12, 2015, an Agreement was signed by 195 nations in Paris for a global effort for low-carbon economy and energy (New York Times). The effort is to reduce emission of green house gas (GFG) by less use or replacement of fossil fuels. The target is to lower climate temperature by 2 °C by year 2050. Converting waste biomass, including the huge amounts of farm animal wastes into biogas as renewable energy will reduce the emission of GHG with a better sustainability. A joint publication by USDA- EPA- DOE (2014) pointed out that the use of biogas from animal manure is much more favorable in terms of GHG reduction compared using conventional fuels such as gasoline and natural gas. The analysis indicated that when biogas is produced and used as transportation fuel, the net reduction of GHG emissions is significant.

Effluent or digestate

Discharge and utilization of the daily large volume of digestate from a large digester system present great challenges. The nutrients contents in the digestate, on the other hand, are of high value as soil amendments and organic fertilizer to grow plants and crops when properly managed. Many methods, such as centrifugation, sieving, sedimentation, evaporation, membrane filtration have been used to separate or concentrate the digestate into liquid fertilizer. The separated liquid has to be further treated for safe discharge or irrigation on farmland. Solid residue is converted by a conventional process into compost. None of those separation methods are simple and inexpensive. The composting process is always associated with strong odor and loss of nitrogen, which is key nutrient. Concentrated digestate has been demonstrated of higher quality than the regular aerobic compost, because of the high retention rate of nitrogen, phosphorus and potassium (NPK) contents and other benefits for plant growth allowing a better production sustainability.

Poultry waste digestion

This author experienced the same financial gain from a UNDP project in China. In 1991, he was invited to help design and operate a thermophilic poultry waste digester in Liu- minying village, Beijing. This digester was constructed for 50,000 laying hens that produced 5 tons of chicken manure daily. It was installed in 1992 and has been in operation for more than 20 years. The initial investment was paid back in less than three years because of the high market value and quality of the new fertilizer converted from the digestate. A lesson was learned. In order to make the biogas system work or and financially feasible, all products and benefits, including energy, carbon credits, organic fertilizer and environmental sanitation, have to be fully developed. In both dairy and poultry cases, it is noteworthy that almost 50% of the total value can be created by converting the digestate into organic fertilizer.

Discovery and development of new products

Anaerobic digestion is not only a bioprocess for waste treatment and biogas production, but also a rich resource of bio-products. In the late 80’s, serendipitously, feather degradation was first observed during the operation of a poultry waste digester on the farm. After two years of painstaking search, a feather-degrading bacterium was isolated that can break down feathers. Subsequently, the keratinase enzyme was purified and the gene encoding this novel enzyme was isolated and sequenced. With fermentation scale up, the enzyme was produced in a quantity sufficient for application research. It was demonstrated that the keratinase can be used for processing feathers to make feather meal more digestible. Finally, it was discovered the keratinase as a feed additive can improve the digestibility of feed protein and promote the growth of young chicks. This series of studies have generated a total of 9 U.S. and international patents.

In year 2000, a biotechnology company called BioResource International (BRI) was established to commercialize this unique enzyme to help poultry producers worldwide save feed costs and now the enzyme product is on the market worldwide. (see reviews, Shih, 1993, 2012, 2015 and website: www.briworldwide.com).The discovery of keratinase followed by technology and commercial development is a perfect model of translational research from science to commerce. On the other hand, it demonstrated the potential wealth of anaerobic digestion for enzyme discovery, gene mining and possibilities of other novel bio-products.

Economics

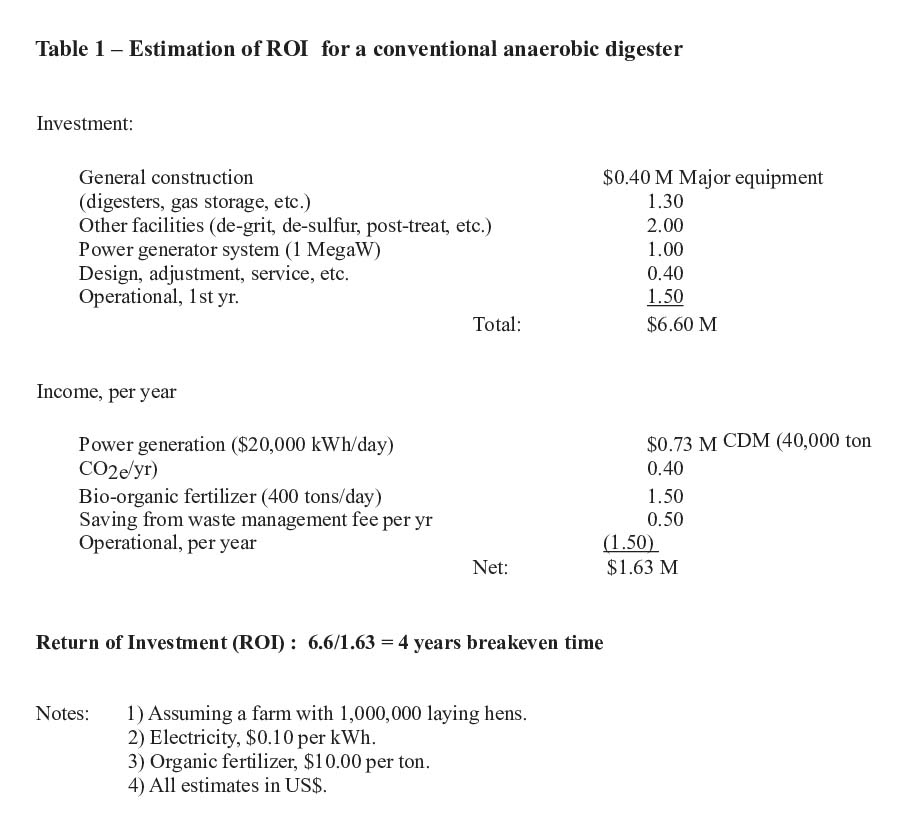

Biogas technology is a maturing technology, ideal for sustainability. Based on currently available, yet limited, information, the author has proposed a virtual model for cost and return estimation. A hypothetical farm raising one million laying hens and producing 100 tons of fresh manure daily can be outfitted with a conventional CSTR large digester system to process the manure daily. Biogas can be produced at a reasonable rate and converted into electricity while digestate can be processed into organic fertilizer. Interestingly, the Return of Investment (ROI) of the large biogas system has a breakeven time only 4 years. Though hypothetical, it is encouraging for follow-up study and improvement.

New technologies

In addition to his first digester design in 1996 (Shih), this author has filed three more patents in the last three years. They are ready for licensing and co-development and briefly described as follows:

- Hydrolytic Degritter (patent pending, filed in 2013). This is a device and method for pre- treatment of animal waste to remove sandy materials, or grits, before entering the anaerobic digester.

- Secondary Solid-Phase Anaerobic Digestion for More Biogas Production (U.S. Patent 9,242,881, 2016; filed in 2013). Biomass is used for secondary solid-phase digestion with liquid digestate from the primary digester to produce more biogas.

- System and Method for Anaerobic Digestion of Animal Wastes (Patent pending, filed in 2015). This is a novel design of a compact and complete digester system including the degritter, the primary anaerobic digester and the secondary digester. While producing both biogas and organic fertilizer, the system is low-cost to build, easy to operate and suitable for both large and small animal farms. The trade name of the new digester system is Holistic Digester™.

Conclusion

In conclusion, anaerobic digestion or biogas technology is a maturing technology and emerging market. However, there is room for improvement for practical applications and commercial development. Based on his forty years of experiences, this author invented a new Holistic Digester™ system, which is compact, low-cost and easy to operate. Most importantly, it produces green energy, reduces carbon emission, and recycles the nutrients to organic fertilizer. It is a holistic or integrated solution to waste problems and, at the same time, promises the sustainability of animal and agricultural production, environment and green energy.

References

New York Times, December 12, 2015.

Shih, J.C.H., Process and apparatus for anaerobic Digestion. (1996), U.S. Patent 5,525, 229.

Shih, J.C.H., Recent development in poultry waste digestion and feather utilization. Poult. Sci. 1993, 72, 1617-1620.

Shih, J.C.H., From biogas energy, feed enzyme to new agriculture. World Poult. Sci. J. 2012, 68, 409-416; Erratum, 68, 803-806.

Shih, J.C.H., Development of anaerobic digestion of animal waste: from laboratory, research and commercial farms to a value-added new product. In Anaerobic Biotechnology, H.H.P. Fang and T. Zhang (eds.), pp. 339-352, Imperial College Press, London, 2015.

US Department of Agriculture, US Environmental Protection and US Department of Energy, Biogas Opportunity Roadmap, 2014.

From The Proceedings of XXV World’s Poultry Congress.