Why is it important and how do we measure it?

Technology and the associated hatchery and equipment continues to advance incubation to levels previously unavailable, which has allowed for much better monitoring and control of the environment in which the embryos develop.

Not only does the modern incubator, particularly Single-Stage, provide tremendous control and flexibility when incubating eggs and developing embryos, controlling and monitoring the room and exhaust surrounding our incubators is also easier. Additionally, new technology and management practices during hatching egg storage and transportation have allowed producers to improve hatchability, sometimes even under less than ideal conditions. The results can be seen in the quality chicks and poults that can be produced and from today’s modern breeders.

However, there are several ‘traditional methods’ of monitoring and evaluating our hatchery operations that are not only beneficial but should be considered necessary. One of these is establishing a routine embryo-diagnosis program which can provide tremendous information that can help hatchery managers to adjust incubation parameters to improve hatchability and possibly most importantly, to improve chick or poult quality. Another one of these ‘traditional’ tools to monitor and evaluate incubation is measuring moisture loss in hatching eggs during incubation. Neither of these ‘traditional’ tools in hatchery management relies on new or modern technology, yet they can provide extremely valuable information from which managers should use to evaluate hatchery performance. Measuring moisture loss is relatively easy yet very beneficial.

However, there are several ‘traditional methods’ of monitoring and evaluating our hatchery operations that are not only beneficial but should be considered necessary. One of these is establishing a routine embryo-diagnosis program which can provide tremendous information that can help hatchery managers to adjust incubation parameters to improve hatchability and possibly most importantly, to improve chick or poult quality. Another one of these ‘traditional’ tools to monitor and evaluate incubation is measuring moisture loss in hatching eggs during incubation. Neither of these ‘traditional’ tools in hatchery management relies on new or modern technology, yet they can provide extremely valuable information from which managers should use to evaluate hatchery performance. Measuring moisture loss is relatively easy yet very beneficial.

Moisture loss in eggs

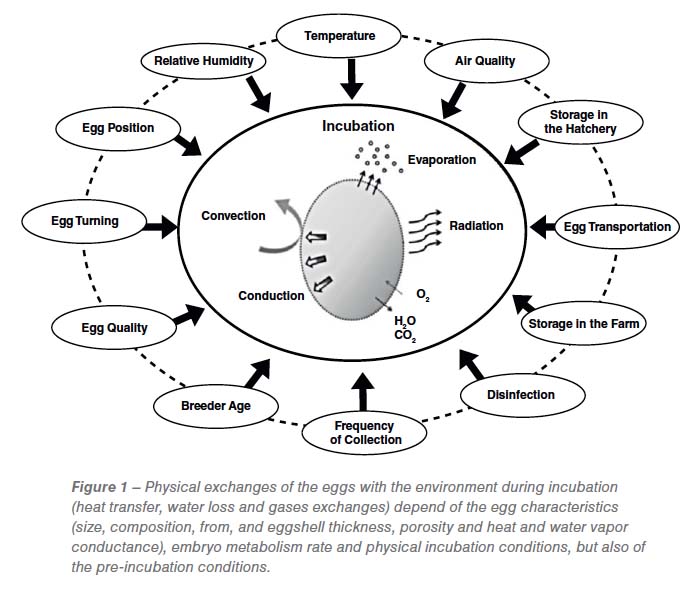

Eggs lose weight during incubation primarily in the form of moisture loss through the shell and shell membrane. The loss of moisture from the eggs follows the ‘Law of Thermodynamics’, in that, molecular diffusion, or simply diffusion, is the net movement of molecules or atoms from an area of high concentration to low concentration. This is a natural or passive movement driven by gradients until both concentrations become equal (i.e. moisture from inside the egg move out and into the air in the incubator). This movement will occur with gases, liquids, and mixtures (i.e. moisture loss during incubation, oxygen-carbon dioxide exchange, Figure 1). So in other words, the predominant factor controlling the loss of moisture from an egg is the percent humidity in the incubator cabinet in relation to the moisture content of the egg. The lower the humidity during incubation, the greater the difference there will be between the moisture components of the egg and the surrounding environment, therefore there will be a greater loss of moisture from the egg as the egg and the surrounding environment work to move towards equilibrium.

Obviously, there are other contributing factors such as egg shell thickness, air temperature, air movement, etc. In nature, the egg membrane and shell thickness and porosity will vary greatly between bird species dependent upon the native environment those birds naturally exist. This is a biological mechanism to control moisture loss during incubation, one in which we try to emulate during artificial incubation. Air temperature will also affect the rate of moisture loss with lower temperatures slowing the rate of moisture loss, such as during egg storage. Air movement or ventilation also contributes to gaseous exchange as a lack of air movement outside the egg will create a halo type effect which will create an environment somewhere in between the egg and the rest of the air and will reduce the gaseous exchange.

Measuring egg moisture (weight) loss

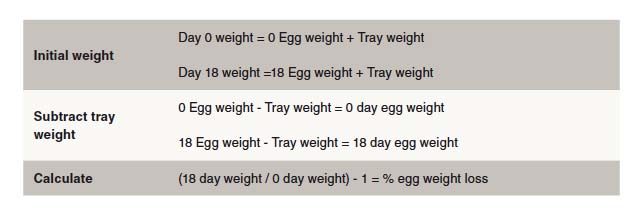

Determining egg weight loss in incubation is relatively easy yet provides valuable information which can help determine the optimum incubation environment. To determine egg weight, or moisture loss, simply weigh several flats or trays of eggs prior to placing them in the incubator. It is best to weight them on the same flat or tray that they will be set on in the incubator. It is not necessary to weigh individual eggs, weighing a group of eggs is best. Tag or identify which eggs were weighed so that the same eggs can be weighed at transfer. At transfer, (about 18 days for chickens, and about 25 days for turkeys and ducks) remove the tagged egg trays and weigh the eggs on the same flat or tray they were weighed on at set. Record the weight then transfer the eggs off that tray and weigh the empty tray again. Subtract the tray weight from both the day 0 weight and the day 18 weight then divide final weight by the initial weight and subtract 1. This will give you the weight loss during incubation. It is important to remember to subtract the tray weight prior to calculating moisture loss.

For chickens and turkeys in multistage incubators, 11-12 % moisture loss at transfer is ideal and for single stage incubation 9-10% moisture loss is wanted. If transfer is not on day 18 (day 25 turkeys) then adjustments should be made to account for difference as the ideal moisture loss indicated above is for a normal transfer time three days prior to pulling the hatch. When these ideal values for moisture loss are obtained, it has been shown that chick quality is also ideal. Controlling moisture loss to the above values helps the embryo to develop at a normal rate and helps the navel to close properly to produce a healthy hatched chick ready to be placed in the brooder facility.

Using moisture loss data

Using the weight loss data gathered and the laws of thermodynamics that control the rate at which moisture is lost from the egg, the values obtained can help to make potential adjustments to the incubation conditions. For instance, if we want 10% moisture loss, but are getting 13% moisture loss then the incubation environment is too dry. If we want 10% moisture loss yet are only getting 7 -8% then there is too much humidity during incubation and the resulting chicks or poults may have open or unhealed navels. From this data hatchery managers can then go back and make adjustments to humidity levels during incubation.

Even with all the sophisticated equipment found in many of our modern incubators and hatcheries, utilizing this data collected directly from the embryo or chick is extremely valuable to hatchery managers. The advanced technology provides so much more control of the developing embryo and implementing this technology is most certainly the direction all producers should be moving towards. However, while incubation is most certainly based upon science and the expertise of researchers and managers, there is also an art to producing and hatching quality chicks and poults. Measuring moisture loss data in our hatcheries should be part of a routine management program, just as embryo diagnosis of hatch residue is utilized. Then taking this information, combined with what is known about the laws of thermodynamics and moisture loss across the egg shell barrier, and evaluating our incubator profiles to give the developing embryo exactly what it needs.