The microbiological status of a hatching egg is highest immediately after the egg is laid. The objective, therefore, is to ensure that quality is maintained throughout the process of egg collection, placement into the on-farm egg storage, and transport to the hatchery.

Quality can be managed if careful attention to detail is followed. Good hygiene practices and careful egg handling are essential every step of the way. Remember, eggs carry an embryo, a living organism, and should be treated with care.

Egg hygiene and collection

The cuticle

The egg has a multilayered system that, combined with good nest hygiene, protects against microbial contamination. This system includes the cuticle, eggshell, shell membranes and proteins in the albumin. The cuticle is the first line of defense. It is the layer of protein that coats the egg (making it look wet directly after being laid) and helps fill in the openings of the pores. Contamination risk is highest within the first 3 minutes after lay because the cuticle needs time to dry and harden.

Eggs with good cuticle coverage are less susceptible to penetration by bacteria. However, the cuticle can easily be removed by washing the eggs with water or scraping/buffing the exterior shell. These procedures, when used to clean a soiled egg, can do more damage than good. Once the cuticle’s protection is lifted, bacteria can easily enter the pores. Although soiled eggs that have been cleaned might hatch as well as clean eggs, there is the potential for an increased incidence of internal egg contamination (exploders). Eggs that explode in the setter or hatcher contaminate other eggs and ultimately contaminate chicks.

Nest hygiene

The nest box must be inviting to the hen to encourage the hen to lay eggs inside the nest instead of on the floor.

- Clean nests and nesting equipment is essential to avoiding contamination.

- Built-up debris should be removed and nesting material cleaned or replaced frequently.

- Mechanical belts should be cleaned often.

Egg handling and collection

Collect floor eggs separately from clean eggs and storage them separate from the nest eggs so that the hatchery can manage the contamination risk appropriately. Floor eggs should be collected as often as possible; more often than nest eggs. Monitor the number of floor eggs and adjust management practices to minimize them. Always wash hands after collecting floor eggs and before each collection of nest eggs.

Collect floor eggs separately from clean eggs and storage them separate from the nest eggs so that the hatchery can manage the contamination risk appropriately. Floor eggs should be collected as often as possible; more often than nest eggs. Monitor the number of floor eggs and adjust management practices to minimize them. Always wash hands after collecting floor eggs and before each collection of nest eggs.

Collect nest eggs a minimum of 4 times a day. Adjust the exact timing so that no more than 30% of the eggs fall in any one collection. When determining collection times, it is important to remember:

- Eggs left in the nest or on belts longer than recommended will have an increased incidence of being cracked or soiled.

- Transition points on belts need to be smooth so eggs don’t pile up and bump into each other.

- Eggs left in conventional nests are subject to toe pecks or soiling from other hens.

Always handle eggs carefully to prevent cracks during collection.

Egg hygiene and disinfection

Eggs should be maintained in a clean state between lay and the egg storage. However, when contamination is suspected or higher than usual, disinfection may be necessary. As always, local legislation should be followed. More recently, the use of formaldehyde has been prohibited in some countries because of the potential risk to human health and safety if improperly used. Therefore, alternatives to formaldehyde fumigation have been sought. Carefully choose the right disinfectant. Some chemicals such as peracetic acid can strip the cuticle completely.

Regardless of the type of disinfection, it should be performed within 2 hours of collection. Eggs should be placed in setter trays for best exposure to the disinfectant; fiber trays are not recommended. Any disinfecting product should be assessed for effectiveness before implementation. Factors to consider include:

- Eggshell bacterial counts before and after treatment.

- Egg content bacterial counts after treatment.

- The impact on cuticle cover (which can be seen under UV light).

- Hatchability.

It is not recommended to wash hatching eggs.

Egg storage

Equipment

Ensure coolers, humidifiers, and fans (if used) are well maintained and clean.

- Avoid using humidifiers with reservoirs that are difficult to clean and promote bacterial growth.

- Water quality should be checked when using steam humidifiers that are fed directly from the main water supply.

- Spray nozzles should produce a fine mist; replace nozzles if they produce droplets or spatters of water that can make eggs wet.

- Care should be taken to never place eggs directly in front of coolers or humidifiers.

- Prevent drafts from blowing on eggs; they cause rapid changes in temperature and increase moisture loss.

Handling

Eggs need to be cooled as soon as possible to stop cellular growth of the embryo and suspend it in a stage of development (physiological zero) best for short term storage.

- Place collected eggs in an egg storage that has been cooled to a maximum of 15° C (59 °F)

- Ideally, egg storage humidity should be held between 70 and 80% RH, to prevent the eggs from losing too much moisture during storage.

- Eggs should be stored within 4 hours after collection.

- Fill a partially filled trolley by taking eggs to the egg storage to finish loading it, not by rolling the trolley out of the egg storage.

- Equally, trolleys should be filled from the bottom up to avoid placing warmer eggs below cooled eggs.

- Storage temperatures and humidity should be recorded daily and compared to set points.

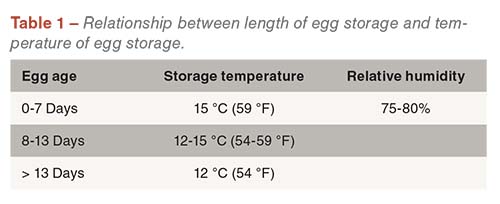

- Storage for longer than 7 days will require cooler temperatures to help reduce the loss of hatch due to embryo cell death and decline in internal egg quality.

Egg transportation

Handling

Handling

Handle eggs carefully during movement between egg storage and the egg truck to avoid damage. Transportation to the hatchery should not allow large jolts or vibrations, if possible. Preventing eggs from cracking is one goal. Another goal is to avoid the excessive jolting which may result in non-viable embryos.

Hygiene

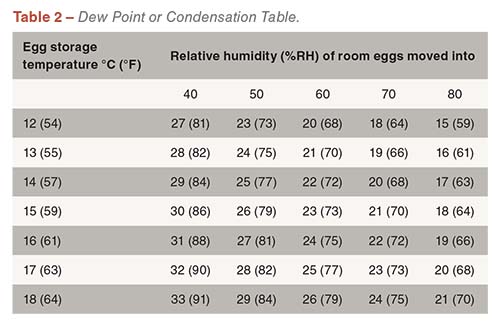

Ensure that transport truck is cooled to the same temperature as the farm egg storage room to prevent condensation on the egg, thereby reducing the risk of contamination. Condensation occurs when eggs are moved from a cold environment into warmer, more humid conditions. Once the eggs cool down again, the condensation will be drawn in through the egg pores and can carry bacteria with it into the egg. Table 2 gives the shell temperature that will result in condensation when moving eggs into a wide variety of temperatures and humidity. For example, if the eggshell temperature is 12 °C and the eggs are moved to a room that is 20 °C, the RH should be <60%, to prevent forming of condensation.

Ensure that transport truck is cooled to the same temperature as the farm egg storage room to prevent condensation on the egg, thereby reducing the risk of contamination. Condensation occurs when eggs are moved from a cold environment into warmer, more humid conditions. Once the eggs cool down again, the condensation will be drawn in through the egg pores and can carry bacteria with it into the egg. Table 2 gives the shell temperature that will result in condensation when moving eggs into a wide variety of temperatures and humidity. For example, if the eggshell temperature is 12 °C and the eggs are moved to a room that is 20 °C, the RH should be <60%, to prevent forming of condensation.

While cooler storage temperatures (12 °C) are important for eggs > 13 days, it is difficult to move these eggs from the egg storage without condensation forming. It is recommended that these cooler eggs are placed in a second egg storage running at 18 °C and a RH below 50% for 24 hours before set. This will allow the egg temperature to increase without causing condensation.

Equally, in tropical climates, eggs may need to be moved to the hatchery several times each day instead of cooled on farm as these eggs will almost certainly sweat when moved from a cooler egg storage.

Other considerations during egg transportation:

- Check that the egg truck is clean, disinfected, and dry before eggs are loaded.

- Check that the egg storage and truck environmental conditions are the same and maintained during transport.

- Make sure loading time of eggs into the truck is minimal. This will reduce the possibility of condensation forming on the egg shell surface because of changes in temperature.

- Always shelter eggs from rain or snow. Eggs that are wet should be allowed to dry before they are placed into a cooler environment.

Summary

The quality of a hatching egg is as good as its care throughout the process of egg collection, placement into the egg storage, and transport to the hatchery.

To maintain hatching egg quality the following areas require attention to detail:

- The cuticle of the egg.

- Nest hygiene.

- Collection times.

- Egg storage in the trolley.

- Environmental condition of the on-farm egg storage.

- Egg storage coolers and humidifiers.

- Transportation temperatures and handling.