Dr. Kelley Wamsley and colleagues at the Mississippi State University Poultry Science Department recently completed a research project that investigated how broilers respond when fed phytase enzymes of different optimal pH ranges alone or in combination.

Overall data did not signify that feeding multiple phytase enzymes will contribute to significant improvements for the commercial broiler industry. However, findings did suggest that more attention towards calcium and available phosphorus ratios can further the efficacy of phytases.

Phytase is an exogenous enzyme that is commonly incorporated into commercial broilers diets to increase the digestibility of phytate phosphorus. This is significant because a large majority of the ingredients used for poultry feed are plant-derived and contain phytate. Phytate hinders the nutritional potential of diets and broilers growth performance, leading to unreached maximal economic gain. Phytase inclusion in diets provides broiler production advantages, such as improved growth performance and better nutrient digestibility.

Due to the expense associated with feed, it is common for poultry nutritionists to formulate diets on a least-cost basis to maximize profit. However, lower priced ingredients typically contain higher amounts of antinutrients, like phytate.

The objective of this research project was to determine the effects of feeding combinations of phytases with varying optimal pH ranges. The researchers theorized that if combinations of different phytases are more effective than singular use, the nutritive quality of feedstuffs would be enhanced; thereby, improving broiler production, lowering feed costs and reducing environmental excretion of phosphorus.

Two experiments were conducted. In experiment 1, broilers were reared in raised wire cages from 0-14 days to investigate the potential synergy of three different phytase enzymes of varying biochemical properties when fed alone or in combination with low phytase activities (120 or 240 FTU/kg). Data obtained demonstrated a potential synergy with the supplementation of two phytases combined at a higher phytase activity level (240 FTU/kg), as identified from ileal IP6 lower ester concentration, increased digestibility (calcium, phosphorus, and select amino acids) and tibia ash (indicating greater phytate degradation). In experiment 2, the two higher performing phytases from experiment 1 were used to address limitations recognized in experiment 1, including:

- utilizing a broader and more practical range of phytase activity (250 or 1500 FTU/kg);

- implementing three diets varying in calcium and available phosphorus; and

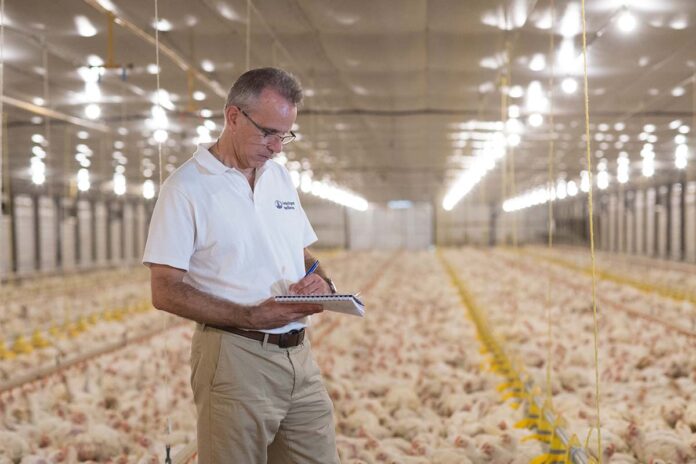

- employing an entire grow-out of broilers within experimental floor-pen facilities.

These data demonstrated that feeding diets lowest in calcium and available phosphorus along with 1500 FTU/kg of a single phytase resulted in improved broilers performance, tibia ash (mg/chick and concentration of select minerals) and nutrient digestibility (calcium, phosphorus and select amino acids). This strategy also demonstrated improved thigh weight at processing and indicated greater phytate degradation. Additionally, there was some indication of synergy for the use of combined phytase at 250 FTU/kg within diets of medium calcium and available phosphorus levels (relative to reduced nutrient diets alone); however, performance was not maximized.

Overall, data do not indicate that feeding multiple phytase enzymes will contribute to significant improvements for the commercial broiler industry; however, these data do suggest that more attention towards calcium and available phosphorus ratios can further the efficacy of phytases. Further research on multiple enzyme use in broilers diets is warranted and could provide valuable economic and environmental insight on the strategic use of exogenous enzymes for the commercial poultry industry.

The research was made possible in part by an endowing Foundation gift from Peco Foods and is part of the Association’s comprehensive research program encompassing all phases of poultry and egg production and processing.

A complete report, along with information on other Association research, may be obtained through USPOULTRY’s website, ww.uspoultry.org