Single-stage versus multi-stage

During the past decades, single-stage incubation has gained popularity and eventually replaced multi-stage incubation as the dominant incubation method. This is not surprising, since it brings optimal hatch results, extraordinary chick quality and significant improvements in post-hatch performance.

In multi-stage incubation, the hatchery manager has little or no control over parameters such as CO2-levels or humidity, since eggs of different flocks, sizes and development stages are all together in one incubator. With single-stage incubation, on the other hand, he can identify the parameters that influence embryonic development (first 9 days of incubation), embryonic growth (day 9-18 of incubation) and the hatching process (last three days of incubation) and adapt them accordingly. As a result, parameters that used to be irrelevant in multi-stage incubation because they had little or no flexibility have become highly important in single-stage incubation methods.

Ventilation by CO2 or by humidity?

This leads to a number of questions regarding the management of incubation parameters. One of the most important questions is related to ventilation: if both CO2-levels and weight loss (humidity) are managed by ventilation, which of the two elements should be controlling the ventilation actuator?

To answer this question, we first need to look into both parameters more closely.

1. Humidity

The humidity levels in the incubator determine the amount of weight (water) the eggs will have lost by hatch time. Losing water through the egg shell allows the embryo to build up an internal oxygen air cell that is used for the transition to lung respiration after internal pipping. It is therefore vital that the eggs have lost the correct amount of water by the internal pipping phase.

For chicken eggs, the general guideline for weight loss used to be set at 11-12% of the initial weight at day 18 of incubation (in other words, by transfer to the hatcher). This implied that the majority of weight loss had to be achieved during the first 18 days in the setter. The reason for that was that humidity levels in the hatcher were relatively high, and it was not possible to fine-tune these levels unless the hatchery manager intervened manually.

Nowadays, however, modern ventilation control systems in the hatcher can lower or raise the humidity levels automatically. As a result, it is no longer necessary for the eggs to lose the majority of their weight by day 18. The guideline for target weight loss has therefore been dropped to 10-11% at day 18, provided of course that modern, automated hatchers are used.

2. CO2

Numerous studies (e.g. Willemsen et al., 2008) have indicated a clear correlation between the amount of CO2 in the air and embryonic development. As shown by extensive field trials organized by Petersime, CO2 control leads to significant gains in post-hatch mortality and to better feed conversion ratios, meat yields and overall final bird weight at slaughter.

In the setter, initial higher CO2-levels have a positive impact on the development of the cardiovascular system. From day 9 onwards, levels are lowered again to stimulate physical growth.

In the hatcher, CO2-levels can be adapted to trigger the different phases in the hatch process, resulting in significant gains in hatch timing and chick uniformity.

3. Guideline for ventilation control

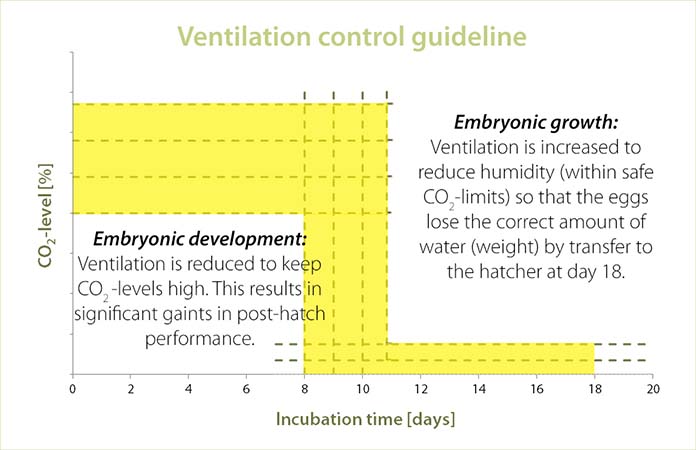

During embryonic development (first 9 days of incubation), ventilation should be determined by CO2-levels. High initial CO2-levels lead to important gains in post-hatch performance, therefore, ventilation should be limited in this phase. Artificial humidification is not necessary since humidity levels will be kept high through evaporation of the eggs. An additional advantage of reduced ventilation in the first 9 days of incubation is that temperature uniformity throughout the setter will be optimal.

During embryonic growth (days 9-18), it is still advisable to ventilate according to CO2-levels because ventilation by humidity could generate dangerously high CO2-levels. However, the main objective during this phase should be to achieve the optimum humidity levels (within safe CO2 limits) in order to reach the optimum percentage of weight loss.

An example profile is shown in the Figure 1.

Theoretically, all flock type, ages, etc. can be incubated within this guideline. However, if choices need to be made, make sure that achieving the correct amount of weight loss by transfer time is never compromised.

In practice: working with bandwidths

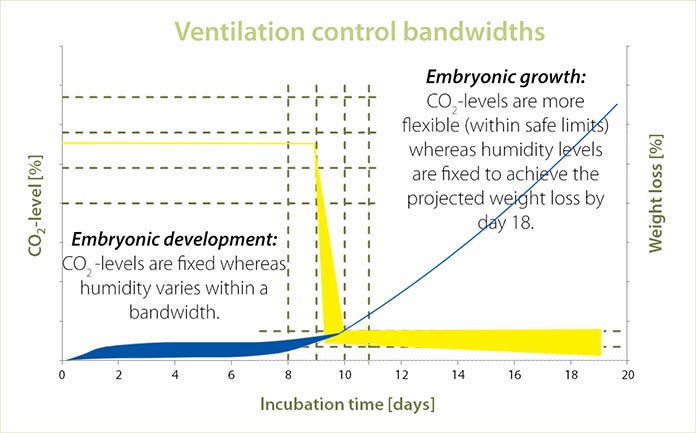

In practice, the CO2 and humidity levels will vary within bandwidths that occur in any large-scale commercial incubator.

During embryonic development, CO2-levels are fixed whereas the relative humidity (weight loss) varies within a bandwidth.

During embryonic growth, CO2-levels are more flexible (within safe limits), but humidity levels are fixed in order to make sure that the target of 10-11% of weight loss is achieved by day 18.

References

Willemsen H, Tona K, Bruggeman V, Onagbesan O, Decuypere E, Effects of high CO2 level during early incubation and late incubation in ovo dexamethasone injection on perinatal embryonic parameters and post-hatch growth of broilers. British Poultry Science, 2008, 49(2), 222-31.