A primary goal in raising poultry is meeting the bird’s basic needs with regards to adequate temperature, air quality, food, water, light and protection from disease. The other aspect of raising poultry is to minimize stress so that you maximize growth, development and feed conversion. When speaking about poultry house environmental control in order to gain control of bird performance, health and comfort one has to control the house air exchange rates, where the fresh air enters a house and how it moves within a house. This concept will be true regardless of cold, warm or hot weather, and despite bird age or species.

Cold Weather

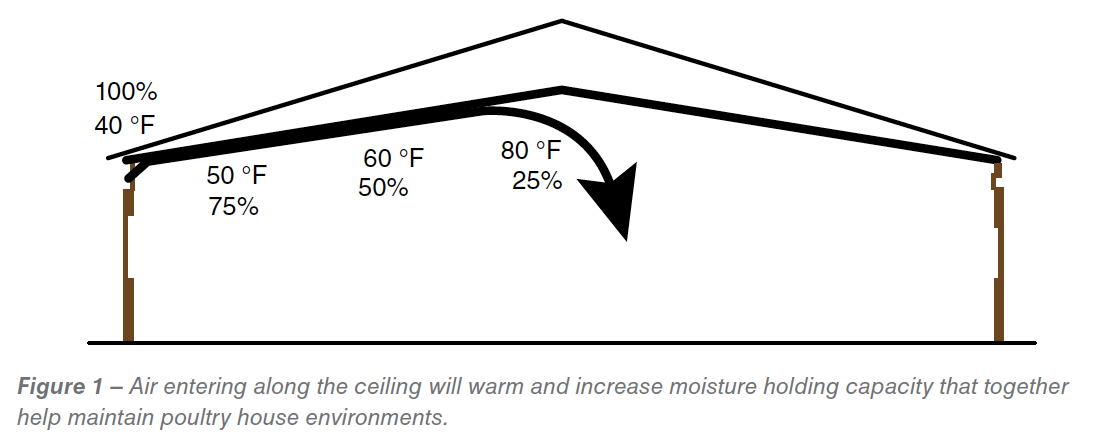

A tight house is needed in order to control where the fresh air enters a house. By controlling where the air enters it allows the air to be conditioned to not only prevent chilling the birds but also to make the air more efficient in controlling moisture. In cold weather or during minimum ventilation, the air is generally brought in through inlets near the top of the sidewall or in the ceiling and directed towards the middle of the house along the ceiling. This is done in order to warm the cooler incoming air so that it does not chill birds at the floor, but also to reduce the humidity of the incoming air so that it can hold more moisture (Figure 1). Otherwise, if the unconditioned air fell directly to the floor or if it actually entered at bird level, it would not only possibly chill birds but it would result in wet litter. Heat will rise to the ceiling resulting in stratification. By bringing fresh air into the house along the ceiling one is taking advantage of this and can use it to provide optimal conditions for the birds.

As the air temperature increases, the moisture holding capacity level increases. For every 20 °F increase in air temperature the moisture holding capacity doubles which means the relative humidity is decreased by half. Because of the importance of controlling where air enters the poultry house, a static pressure test should be conducted in each house to determine it tightness (or how much it leaks). A static pressure test involves closing all the inlets and doors and operating enough fans to get one cubic foot per min (CFM) per square foot. The tighter the house the higher the static pressure will be. The lower the static pressure the more leakage that is present. In general, modern poultry houses that have a static pressure of 0.13 inches of water column is considered reasonably tight for an acceptable level of environmental control.

Houses with higher static pressure test results not only provide better environmental control, but are more energy efficient. In houses with outdoor access, the doors should seal tightly to minimize air leakage and ideally be insulated to minimize condensation issues during cold weather. Condensation will contribute to the house moisture levels making it more difficult to maintain dry floors and lead to increased caking of the litter.

A point to consider in houses with outdoor access is the amount of inlet opening. During cold weather a poultry house is typically operated under a negative pressure ranging between 0.10 to 0.15 inches of water column. This is controlled by inlet opening and as the doors open more or if there are more doors open, the static pressure will decrease and the incoming air will not be directed far enough across the ceiling to be conditioned properly. Another issue with the low pressure is that more air tends to be pulled in near the vicinity of the fans instead of evenly down the length of the house. In houses with outdoor access doors open the house may have to be run with either natural ventilation with large sidewall/curtain openings or the house will have to be run at a low level of negative pressure.

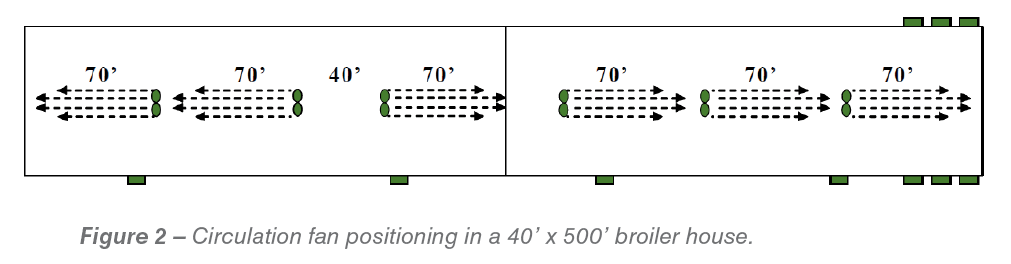

Circulation fans can improve the environment by distributing air from warmer parts of the house to cooler areas (Figure 2). These fans will also increase the air movement within the house. An ongoing project evaluating the use of 1/3 horse power 24” fans that move more air in combination with ventilating the house to keep relative humidity below 60% is yielding very positive results in terms of house moisture, floor moisture and foot pad scores.

Hot Weather

House tightness is just as important in the summer as it is during cold weather. In hot weather, modern poultry houses utilize tunnel ventilation to move air over the birds at speeds of 500-700 ft/min. Evaporative cooling systems are used when house temperatures exceed 85 °F to augment the cooling of the birds by tunnel ventilation through the decrease in air temperature. This combination provides the heat removal and cooling needed to prevent heat stress. In poultry houses with outdoor access the air entering through bird access doors result in additional heat buildup down the length of the house resulting in greater temperature differences from front to back. Another observation is that poultry houses with outdoor access with a lot of tunnel fans operating can have large differences in static pressure from one end to the other when the doors are open. This can result in more air being drawn into the house closer to the fans than near the front of the house near the pads. Not only will this create different environments along the length of the house, but the air speed through the bird access doors can be so high that it may discourage birds from going outside.

Using the concept of negative pressure tunnel ventilation in poultry houses with outdoor access is very difficult. There is too much inlet opening and the inlets are in the wrong place (along the length of the house at the floor). The same concept mentioned earlier during cold weather will need to be considered in hot weather as well and this is to operate the house at a low level of negative pressure. The air speeds will not be as great, but the temperature uniformity will be more even throughout the house. High pressure fog systems can help this situation some when needing to run more fans, but they will need to be operated in a manner to prevent excessive wetting of the birds and floor. The location where the fogging nozzles should be considered and will be different than poultry houses without outdoor access.

The principles of modern poultry house ventilation can be applied to poultry house style with outdoor access. The difference is implementation. Achieving better ventilation will involve house design as well as management considerations in the future. More detailed information on the principles and management regarding poultry house environmental control can be found on the website www.poultryventilation.com.

While the focus in the previous sections has been on ventilation of poultry houses with outdoor access, other management decisions will have to be made in order to achieve optimum performance in this style of housing. This might include bird density, breed, diet, lighting programs and even house design.

From the 2018 MPF Proceedings – Midwest Poultry Federation Convention