Hatchability, chick quality and post-hatch performance improve substantially when embryo-response parameters are actively controlled during incubation. The BioStreamerTM concept, developed by Petersime, continually monitors an embryo’s behaviour and adapts the incubation environment to its specific needs. Petersime has put considerable effort into researching optimum incubation profiles. Some of the most striking results are presented in this article.

During incubation, a chick embryo has no self-control mechanisms. So, the environment should adapt to the requirements of the embryo, and not vice-versa. Since each batch of hatching eggs is unique, it requires a unique incubation environment achieved in real-time conditions. Traditional single-stage incubation systems use averaged incubation parameters, ignoring differences in egg age or size, flock age, shell porosity, genetics, and other important variables.

Constant interaction with the embryo

Petersime’s Embryo-Response IncubationTM process constantly and interactively optimizes the incubation environment. The process controls ventilation, humidity and temperature according to the embryo’s particular needs. Scientific research and extensive field tests have proven that hatchability and chick quality, as well as post-hatch performance, benefit greatly from active control of bio-response parameters during incubation.

Real-time eggshell control: top quality day-old chick

Embryo temperature is another, and perhaps the most important key parameter in reaching optimal hatchability and chick quality. Deviations from the optimal temperature may negatively influence the development, growth and maturation of the embryo. During the first stage of the incubation process, heat must be transferred from the air to the egg.  After approximately one week, the embryo’s metabolic heat production rises, and incubators have to start cooling instead of heating. So, air temperature, humidity, and air velocity in the incubator have to be adjusted continuously to maintain the right embryo temperature. But how to measure the embryo’s temperature? Invasive measuring is the surest method, but it is destructive and unsuitable for real time measurement in commercial hatcheries. Measuring the temperature of the eggshell with contact-less infrared sensors solves the problem.

After approximately one week, the embryo’s metabolic heat production rises, and incubators have to start cooling instead of heating. So, air temperature, humidity, and air velocity in the incubator have to be adjusted continuously to maintain the right embryo temperature. But how to measure the embryo’s temperature? Invasive measuring is the surest method, but it is destructive and unsuitable for real time measurement in commercial hatcheries. Measuring the temperature of the eggshell with contact-less infrared sensors solves the problem.

Petersime’s patented OvoScanTM system (Figure 1) continuously adapts the incubator temperature to the eggshell temperature. Petersime conducted experiments to assess the effect of OvoScan™ on both hatch and post-hatch performance. In a setter not monitored by OvoScan™, the eggshell temperature typically diverges from the required level during the exothermic stage of incubation. With OvoScan™ control, the eggshell is rigorously kept at the pre-set temperature of 100°F. The observed results in detail:

- Gain in hatchability: 0.4% (average).

- Gain in day-old chick weight: 1.8 g (average).

- Gain in day-old chick length: 1.4 mm (average).

- Gain in end weight: 60.2 g (average).

Dynamic weight loss: 1.88% gain in hatchability

One important parameter is the weight loss of the eggs in the setter. For optimal hatchability, eggs need to lose up to 14% at point of hatch (typically 10-12% at transfer) of their weight (in the form of water vapour) during incubation.

Petersime developed and patented the Dynamic Weight Loss SystemTM (DWLSTM) to control the humidity level in the incubator and thus manage this water-weight loss. The DWLSTM measures the eggs’ weight during each incubation stage and automatically adjusts the incubator’s humidity level to achieve the optimum weight-loss trajectory.

Petersime developed and patented the Dynamic Weight Loss SystemTM (DWLSTM) to control the humidity level in the incubator and thus manage this water-weight loss. The DWLSTM measures the eggs’ weight during each incubation stage and automatically adjusts the incubator’s humidity level to achieve the optimum weight-loss trajectory.

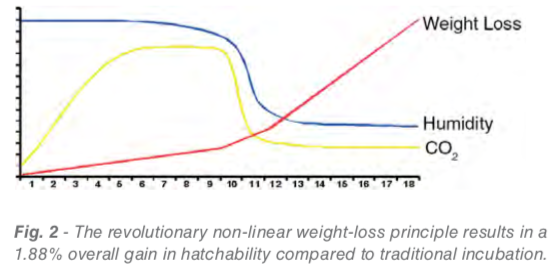

But what is the optimum weight-loss trajectory? To solve this, Petersime introduced a new single-stage incubation concept: the non-linear weight-loss principle (see Figure 2). Field tests, comparing this dynamic weight-loss principle with traditional single-stage and multi-stage incubation, were conducted on nearly 4 million eggs and showed an overall gain in hatchability of 1.88%.

CO2 control: improved embryo growth

The third essential parameter that is meticulously controlled in the BioStreamerTM concept is gas exchange. The patented CO2NTROLTM (a real-time CO2 management device) controls the CO2 level in the setters, which has a beneficial effect on the development of blood vessels and embryo growth and works hand in hand with the DWLSTM principle which emulates much closer the natural incubation conditions experienced by the egg in the nest. In addition, precisely timed CO2 stimulation in hatchers leads to simultaneous pipping and hatching as well as improved chick quality.

Post-hatch performance improved as well

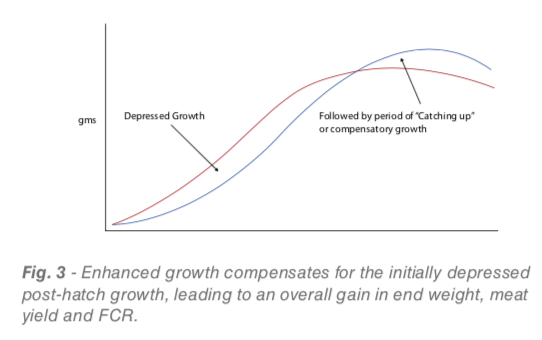

With a series of field tests (over 2.5 million eggs in total) in a commercially-integrated site, the non-linear weight-loss method clearly and consistently induced a pattern of initially depressed growth, followed by a catching-up or compensatory post-hatch growth (see Figure 3). This pattern leads to an overall gain in end weight, meat yield and feed conversion rate, as well as lower post-hatch mortality. The following results were observed:

With a series of field tests (over 2.5 million eggs in total) in a commercially-integrated site, the non-linear weight-loss method clearly and consistently induced a pattern of initially depressed growth, followed by a catching-up or compensatory post-hatch growth (see Figure 3). This pattern leads to an overall gain in end weight, meat yield and feed conversion rate, as well as lower post-hatch mortality. The following results were observed:

- Reduced post-hatch mortality: -0.23% (average).

- Enhanced post-hatch growth: 64 g per 39.4 days (average).

- Improved feed conversion rate: average -0.019 (average).

- Improved meat yield: 1.2% of slaughter weight (estimated 0.9% of live weight).

Narrowing the hatch window and improving chick quality

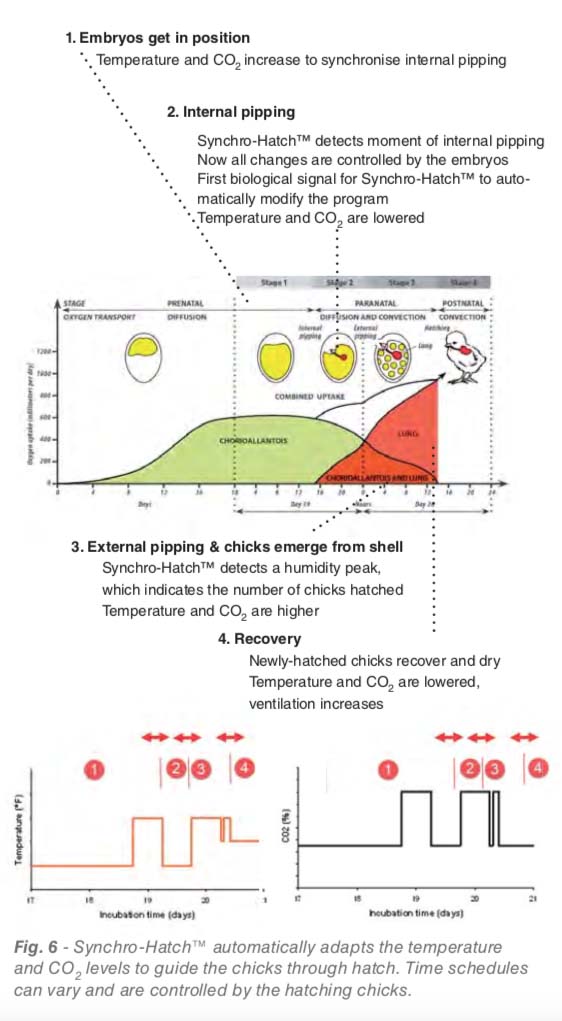

Working with world-renowned universities, Petersime is continuously searching for ways to optimize other promising embryo-response parameters and further optimize the incubation profile. An approach that has resulted in the recent addition to the Petersime embryo response control parameter Synchro-HatchTM. A system that further emulates the nest interaction between parent bird and the hatching egg by sensing the point at which the chick moves towards the air cell and ultimately externally pipping and escaping the confines of the shell and achieving full lung action.

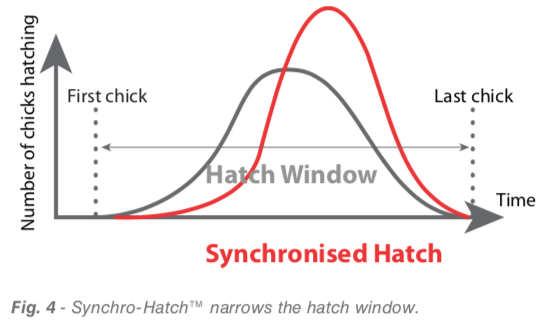

The results of working with new technologies are significant. Synchro-Hatch™ reduces the hatch window with four to six hours. The narrower the hatch window, the more uniform chicks are, enhancing both productivity and welfare.

Extensive in-house trials and research in commercial hatcheries show that day-old chicks

- are significantly more uniform,

- are generally calm, but active and responsive when stimulated,

- have a stronger and more robust appearance,

- higher body weight,

- better feed conversion ratios,

- lower postnatal mortality rates,

- better efficiency in slaughterhouses,

- total higher meat output in the end.

How does Synchro-Hatch™ work?

Synchro-Hatch™ gives the embryos the same signals and stimuli as it would experience from the attentive mother bird in nature and offers optimal hatching conditions. In nature, the parent bird does not sit back and watch the hatch happen. She intervenes and interacts during the entire process. During the hatching phase, she returns to the nest and sits on the eggs for the majority of the time to guide the chicks to hatch. This affects the rate of gas diffusion, the moisture exchange and the heat dissipation during the four stages of hatch.

Synchro-Hatch™ gives the embryos the same signals and stimuli as it would experience from the attentive mother bird in nature and offers optimal hatching conditions. In nature, the parent bird does not sit back and watch the hatch happen. She intervenes and interacts during the entire process. During the hatching phase, she returns to the nest and sits on the eggs for the majority of the time to guide the chicks to hatch. This affects the rate of gas diffusion, the moisture exchange and the heat dissipation during the four stages of hatch.

It is wrong to say that Synchro-Hatch™ delays and/or forces the hatch to occur. Correct is to say that Synchro-Hatch™ gives the encapsulated chick the same signals and stimuli and guides the chicks in the same way as it would naturally expect in the nest from the parent bird. It thus offers the optimal and most natural hatching conditions.

The technology uses two detection principles to detect the evolution of the hatch and how far the hatching has progressed:

- the moment of internal pipping and,

- the detection of the humidity peak.

What happens during hatch?

Natural treatments during sensitive stages

By having a better understanding of the hatching process and the interaction between mother hen and the embryos, we are able to provide natural treatments to the embryos during sensitive stages which have a long-lasting effect. Letting the chicks decide when they are ready to move forward to another stage of hatch with modern sensors and technology has proved to be the most consistent and certain way to achieve a narrow hatch window and uniform chicks of optimal quality. We are now able to provide the optimal conditions for guiding chicks during hatch that are not controlled on time base, but on the real biological signals emitted by the batch of chicks.

Embryo-Response Incubation™, Petersime’s patented technology, optimizes incubation conditions by listening to the natural needs of the embryo. It helps hatchery managers gain even more insight into the incubation process and enables them to more closely approximate the desired incubation profile in the setter. To make sure hatchery managers get the maximum out of their BioStreamerTM, Petersime provides professional training and advice.

For questions or more information regarding training please contact Petersime’s training coordinator at training@petersime.com