Almost all of us, the poultry people, know what biosecurity is about. For the investors, it means spending lots of money to prevent disasters, and for the employees, it means many difficulties to prevent troubles! Taking showers, changing clothes and boots, cleaning and disinfecting, controlling rodents and insects, limiting entrances to the farm and so many other tasks are examples of measures we have to take to decrease the risk of disease occurrences in farms or to prevent the disease from spreading to the other farms.

Dr. Makan Hooshangi (DVM)

Veterinarian, Turkey Management Specialist

There are many academic and linguistic definitions for “biosecurity” and there are also many useful approaches found on the web, but how about the preliminaries such as the whole plan design or the materials used in buildings and equipment? How important are such considerations in influencing the whole procedure of biosecurity in a poultry farm? The fact is that oftentimes simple things which we do not pay enough attention to have huge effects!

Biosecurity is an expensive practice that starts with the very first steps of establishing a farm or a hatchery

These include the premises’ location considerations including the distance to other farms or high-risk areas, local climate, and the vegetation of the area. As these are the initial requirements of respecting biosecurity regulations, any mistake or miscalculation in these respects will be irreversible! Moreover, the design and the materials of the whole site and the buildings are the next crucial factors for the biosecurity process. Underestimating the importance of these factors will be an expensive mistake and cannot be easily corrected after finishing the constructions, or will not be cost-effective to be corrected. Therefore, it is indispensable that the above considerations be taken seriously prior to the construction phase. The separation of high-risk and low-risk areas in the farm, as the first and second biosecurity zones, the correct design of high-risk access routes (feed trucks, etc.), the houses’ exhaust fans direction, the sewage system, the floor slopes, the isolation type, the surface drainage design, the location and direction of each building and facilities, etc. are issues that must be taken into consideration when designing and constructing poultry sites. In addition, the site should be designed in a way that as far as possible, no CCTV or controlling person be needed for biosecurity watch. Using one-way paths, dividing walls, fixed windows or other similar considerations that can reduce the biosecurity breaches to zero can be easily applied in the designing phase.

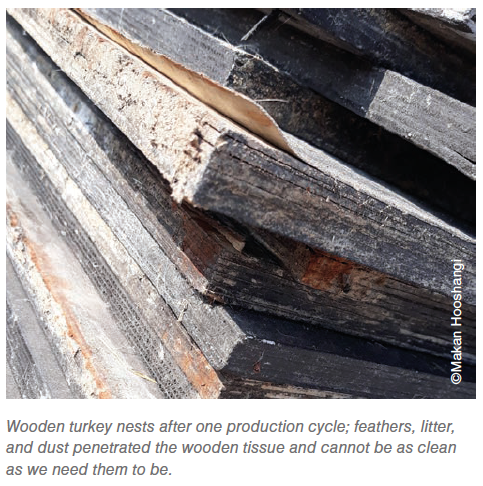

Apart from locating, designing, and constructing a farm, one of the most important considerations in biosecurity is the materials used in buildings or in the equipment. On a poultry site, especially in farms and hatcheries, all the surfaces must be washable with the least perforations, seams, joints, or folds. Using wood, PU foam, fabric or glass wool in structures or equipment are mistakes which cannot be corrected easily. None of these materials can be washed or disinfected properly and they will be the causes of continuous disease occurrences in farms, one cycle after the other. Usually, correcting such buildings or replacing such equipment is very expensive. On the other hand, continuing the job despite such deficiencies is not cost-effective either. It is an expensive dilemma!

The fact is that no practical disinfection can be effective on such surfaces or notches. The microorganisms in organic residues inside wood, PU foam or glass wool, etc. are almost unreachable! That is a big issue in many farms, especially the old ones. So many efforts and resources are wasted because it was not considered before starting the construction or before buying the equipment.

As many businesses, poultry farming is a specialized business, sometimes very complicated, and it needs different professionals to work together to fulfill the needs and comply with the standards, especially biosecurity and hygiene standards. It is crucial for all these professionals to work as a team and look at the job with their different views. However, they must be familiar with the critical points of the job. Mistakes turn into disasters easily and rapidly in this job. All the equipment and facilities are supposed to serve the rearing and growing the birds, so it is important that every single matter in a poultry farm, even seemingly unrelated ones such as engineering tasks be checked and reconsidered by the practical animal science professionals, farm managers, and veterinarians.

As many businesses, poultry farming is a specialized business, sometimes very complicated, and it needs different professionals to work together to fulfill the needs and comply with the standards, especially biosecurity and hygiene standards. It is crucial for all these professionals to work as a team and look at the job with their different views. However, they must be familiar with the critical points of the job. Mistakes turn into disasters easily and rapidly in this job. All the equipment and facilities are supposed to serve the rearing and growing the birds, so it is important that every single matter in a poultry farm, even seemingly unrelated ones such as engineering tasks be checked and reconsidered by the practical animal science professionals, farm managers, and veterinarians.

The equipment plays a significant role in complying with the principles of biosecurity in the operating phase. There is a wide range of equipment used in a poultry farm, from clothes and boots to automatic nests and ventilation systems. Equipment helps do the job correctly, quickly, and easily. Without appropriate equipment, the job would be harder, and more energy consuming, so the risk of misperformance would be higher. Almost all equipment used on a poultry site, depending on where they are used, should be washable or cleanable as much as possible. Some equipment such as nests, AI machine, drinkers, feeders, light traps, trolleys, etc. should be washable. Non-washable equipment which are made of fabric, wood, or cardboards, should be changed before the new cycle. Some other equipment such as computers and electronic devices cannot be washed, nor can be changed every cycle. Such equipment must be well-sealed to avoid dust penetration. For cleaning, a high-pressure air pump and a clean tissue or brush can be used. After cleaning, they can either be disinfected by a tissue and disinfecting solution or fumigating by formaldehyde or ozone gas, depending on the type of the equipment and the materials used.

Using smooth and washable materials for equipment is sometimes hard or expensive, but keep that in mind that the damages will be much more expensive. Most of the pathogens are very sensitive to environmental conditions and can be easily neutralized on a clean surface, but in the presence of organic residues, their resistance would be significantly higher. Moreover, the effectivity of disinfectants significantly decreases in the presence of organic residues. To have an idea, H5N1 virus can live under two weeks at 4 °C outside the host’s body at best, if protected from sunshine and high %RH; but the virus was found to survive up to eight weeks in dry and wet feces at 4 °C.

Using smooth and washable materials for equipment is sometimes hard or expensive, but keep that in mind that the damages will be much more expensive. Most of the pathogens are very sensitive to environmental conditions and can be easily neutralized on a clean surface, but in the presence of organic residues, their resistance would be significantly higher. Moreover, the effectivity of disinfectants significantly decreases in the presence of organic residues. To have an idea, H5N1 virus can live under two weeks at 4 °C outside the host’s body at best, if protected from sunshine and high %RH; but the virus was found to survive up to eight weeks in dry and wet feces at 4 °C.

Apart from the materials used in equipment, the design and manufacturing of the equipment are important as any folds or seams can be a hazard in biosecurity of a poultry site. Such areas cannot be easily cleaned and take lots of time and energy to deal with. Usually, the cleaning team does not put enough efforts on these parts and in an optimistic condition, the responsible supervisor would request repetition of the cleaning process. That means wasting lots of time, energy, and money. In spite of all that, they can still be potential hazards.

Indeed, biosecurity can be respected if you really believe in it; if you think about any details of the job, keeping biosecurity principles in your mind. It is not a play or a show to convince people, it is a necessity for our job, black or white, there would be no gray when the time comes. On the other hand, as said, starting from the base upon biosecurity principles will reduce the high costs of biosecurity procedures. The less detergents and disinfectants are used, the less environmental damage is caused, the more money is saved, and the more money is gained! Work wise!