As part of the modernization programs at USDA, FSIS is amending the egg products inspection regulations and is now requiring plants that produce egg products under FSIS inspection to develop and implement Hazard Analysis and Critical Control Point (HACCP) Systems along with Sanitation Operating Procedures (Sanitation SOPs).

Christine Alvarado, Ph.D. – M.S., Ph.D. Food Science/Poultry Science Texas A&M University Technical Service Manager, Arm and Hammer

The new requirements will be consistent with the current FSIS requirements of meat and poultry regulations and will require egg product facilities to write and implement a HACCP plan and Sanitation SOPs which are specific to their operators, facilities, and equipment. This modernization plan will benefit egg products plants by allowing for internal control systems which can remove current barriers to innovation, will align egg product inspection with meat and poultry inspection, and will decrease the outdated current command and control systems used in egg products currently.

SSOPs will be required in accordance with the regulations in 9 CFR parts 416 and 417 (83 FR 6314). Proper sanitation is an important and integral part of food production. Once the sanitation requirements under 9 CFR part 416 are implemented, all plants that process egg products will have to develop, implement, and maintain written Sanitation SOPs to prevent direct contamination or adulteration of product before and during operations (9 CFR 416.11). It is important that establishment personnel read and become familiar with 9 CFR 416 prior to development of a Sanitation SOP.

Sanitation Standard Operating Procedures (SSOPs)

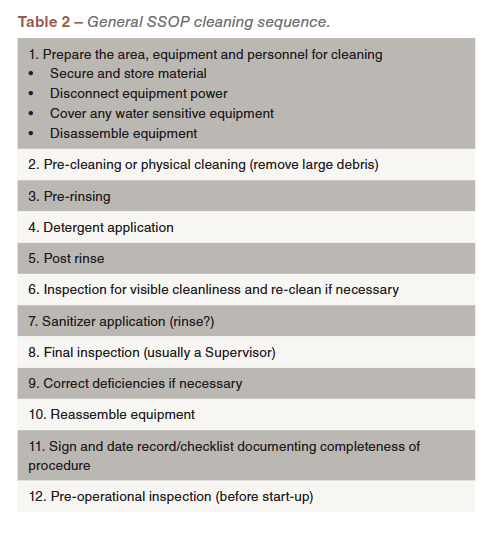

Sanitation SOPs are written sanitation procedures and schedules; the who, what, when, and where of cleaning and disinfection. They describe the sequence of events, step by step, that must be conducted by an employee to prevent direct or indirect product contamination and adulteration. Proper equipment disassembly and reassembly after cleaning and disinfection (before the next day’s processing) along with details of cleaning and disinfection make up pre-operational Sanitation SOPs. Operational SSOPs are those that refer to cleaning and disinfection of equipment, utensils, and facilities, as well as employee hygiene and product handling during operations. Table 1 contains some of the information that may be needed to be included in the SSOPs, as well as some helpful guidelines. Table 2 lists a general SSOP cleaning sequence.

When writing Sanitation SOPs, a good starting point is to make a list of the steps that the plant already observes during cleaning and sanitizing of equipment and the facility. These steps are the backbone of the Sanitation SOP document. Additional questions that the written Sanitation SOPs should answer are: WHAT is being cleaned (equipment, area), WHEN the activity occurs (how often and what time the activity is performed), WHO is doing the cleaning (employee by job title, who is responsible for performing the activity), and HOW the cleaning/sanitization is being accomplished. Each facility should document daily completion of SSOPs. A record of how cleaning procedures are monitored, along with corrective actions taken if cleaning is ineffective or procedures are not followed should be detailed and documented.

When writing Sanitation SOPs, a good starting point is to make a list of the steps that the plant already observes during cleaning and sanitizing of equipment and the facility. These steps are the backbone of the Sanitation SOP document. Additional questions that the written Sanitation SOPs should answer are: WHAT is being cleaned (equipment, area), WHEN the activity occurs (how often and what time the activity is performed), WHO is doing the cleaning (employee by job title, who is responsible for performing the activity), and HOW the cleaning/sanitization is being accomplished. Each facility should document daily completion of SSOPs. A record of how cleaning procedures are monitored, along with corrective actions taken if cleaning is ineffective or procedures are not followed should be detailed and documented.

Once Sanitation SOPs are initially written they must be signed and dated by an individual with on-site authority (Plant Manager or Director). Once the document is signed, the facility agrees to perform the tasks as described. It is important that written procedures are performed exactly as they are written. If procedural changes are adopted, the written SSOPs should be modified and resigned by the Plant Manager or Director.

Establishments must maintain documentation to ensure sanitation procedures are effective. These verification procedures should be conducted daily to provide data on verification and assessment of efficacy of cleaning and sanitation procedures. Corrective actions should be determined and implemented as needed to ensure that adulterated product does not enter commerce.

Specific procedures from 9 CFR 416 regarding sanitation

Development of Sanitation SOP’s (§ 416.12)

- The Sanitation SOP’s shall describe all procedures an official establishment will conduct daily, before and during operations, sufficient to prevent direct contamination or adulteration of product(s).

- The Sanitation SOP’s shall be signed and dated by the individual with overall authority on-site or a higher level official of the establishment. This signature shall signify that the establishment will implement the Sanitation SOP’s as specified and will maintain the Sanitation SOP’s in accordance with the requirements of this part. The Sanitation SOP’s shall be signed and dated upon initially implementing the Sanitation SOP’s and upon any modification to the Sanitation SOP’s.

- Procedures in the Sanitation SOP’s that are to be conducted prior to operations shall be identified as such, and shall address, at a minimum, the cleaning of food contact surfaces of facilities, equipment, and utensils.

- The Sanitation SOP’s shall specify the frequency with which each procedure in the Sanitation SOP’s is to be conducted and identify the establishment employee(s) responsible for the implementation and maintenance of such procedure(s).

Implementation of SOP’s (§ 416.13)

- Each official establishment shall conduct the pre-operational procedures in the Sanitation SOP’s before the start of operations.

- Each official establishment shall conduct all other procedures in the Sanitation SOP’s at the frequencies specified.

- Each official establishment shall monitor daily the implementation of the procedures in the Sanitation SOP’s.

Maintenance of Sanitation SOP’s (§ 416.14)

Each official establishment shall routinely evaluate the effectiveness of the Sanitation SOP’s and the procedures therein in preventing direct contamination or adulteration of product(s) and shall revise both as necessary to keep them effective and current with respect to changes in facilities, equipment, utensils, operations, or personnel.

Corrective actions (§ 416.15)

- Each official establishment shall take appropriate corrective action(s) when either the establishment or FSIS determines that the establishment’s Sanitation SOP’s or the procedures specified therein, or the implementation or maintenance of the Sanitation SOP’s, may have failed to prevent direct contamination or adulteration of product(s).

- Corrective actions include procedures to ensure appropriate disposition of product(s) that may be contaminated, restore sanitary conditions, and prevent the recurrence of direct contamination or adulteration of product(s), including appropriate reevaluation and modification of the Sanitation SOP’s and the procedures specified therein or appropriate improvements in the execution of the Sanitation SOP’s or the procedures specified therein.

Recordkeeping requirements (§ 416.16)

- Each official establishment shall maintain daily records sufficient to document the implementation and monitoring of the Sanitation SOP’s and any corrective actions taken. The establishment employee(s) specified in the Sanitation SOP’s as being responsible for the implementation and monitoring of the procedure(s) specified in the Sanitation SOP’s shall authenticate these records with his or her initials and the date.

- Records required by this part may be maintained on computers provided the establishment implements appropriate controls to ensure the integrity of the electronic data.

- Records required by this part shall be maintained for at least 6 months and made available to FSIS. All such records shall be maintained at the official establishment for 48 hours following completion, after which they may be maintained off-site provided such records can be made available to FSIS within 24 hours of request.

Agency verification (§ 416.17)

FSIS shall verify the adequacy and effectiveness of the Sanitation SOP’s and the procedures specified therein by determining that they meet the requirements of this part. Such verification may include:

- reviewing the Sanitation SOP’s;

- reviewing the daily records documenting the implementation of the Sanitation SOP’s and the procedures specified therein and any corrective actions taken or required to be taken;

- direct observation of the implementation of the Sanitation SOP’s and the procedures specified therein and any corrective actions taken or required to be taken;

- direct observation or testing to assess the sanitary conditions in the establishment.

Conclusions

If bacteria are allowed to survive and grow in egg product processing environment, product may become contaminated resulting in a decrease of microbiological safety. Food- borne outbreaks have been traced back to breakdowns in proper sanitation prior to and during food processing and packaging. Therefore, it is important to establish a written Sanitation SOP to ensure bacteria are eliminated during cleaning and sanitation of food contact and non-contact surfaces. One important way to determine if Sanitation SOPs are effective is to check for microbial growth after sanitation steps have been completed. Non-compliance with Sanitation SOP programs accounts for many non-compliance reports for meat and poultry processing facilities. Given the opportunity, and when not cleaned and sanitized effectively, bacteria on contact and non-contact surfaces will grow and form multiple-layers, referred to as a biofilm. Bacteria in these biofilms are more resistant to detergents and sanitizers than free living bacteria. Proper sanitation can help prevent these biofilms from forming.

Therefore, it is very important that Sanitation SOPs be written as conducted and that they remove bacteria from food contact and non-contact surfaces to ensure safety of egg products.

More information: https://www.ecfr.gov/current/title-9/chapter-III/subchapter-E/part-416