The only way to maintain production is to improve the understanding of precision nutrition so that producers can feed broilers with low or no margin for error. This article will offer some suggestion for nutritionists who need to revisit some concepts and innovate for the future of poultry production.

The future of broiler feeding will mean a paradigm shift for nutritionists. While they are continually challenged to come up with low-cost feed formulations, that provide best-performance results, society is demanding more transparency on how production animals are being fed and treated.

Introduction

The trend toward environmental accountability and sustainability innovation will continue to be strong market drivers. In the future, nutritionists will need to participate in sustainability initiatives; give more attention to ingredient quality; work on phase and sex feeding differentiation; concentrate on particle size and pellet quality, and use additives more efficiently, paying special attention to enzymes. In addition, more AGP-free broilers will be required by consumers. So, new methods of feeding will need to be developed to meet demand.

In the last 50 years, there has been fantastic development in the poultry industry all over the world, and the progress made has been significant. The most important scientific advances are focused on poultry production knowledge; on quick adaptation of backyard production to industrialized business; on low cost of broiler meat and hens’ eggs and on non-cultural and religious restrictions of chicken products. In 2015, data from FATO (the Food and Agriculture Organization of the United Nations) confirms broiler consumption is growing relative to other proteins. However, the future will come with new growth challenges, with cost of production remaining a central issue. Producers must be profitable enough to continue working with full efficiency, while remaining competitive and delivering affordable products.

There are other aspects on broiler production that nutritionists will need to address, and biosecurity is one of the top concerns. With the onset of avian influenza, there is increased attention on broiler losses and farm biosecurity. In addition, many consumers are confused about how avian pathology (Salmonella, Campylobacter, Newcastle Disease) can affect human health. To avoid compromising farm biosecurity, governments, industry professionals and producers must work together to establish and to follow best practices, such as controlling the presence of backyard/wild chickens living close to production farms. In addition, farms must be as clean as possible, and employees must implement sanitation programs, established according to veterinary global recommendations.

In the last 20 years, consumers have been more active in expressing concerns related to what production animals eat, why they grow faster than in the past and how the industry treats them. Society is demanding more information on food safety and animal welfare, and there is an emphasis on sustainable production.

So, how can broiler nutrition and feeding innovate and advance while respecting society concerns and improving technical procedures for sustainability?

First, an improvement in sustainability must be defined. At its base, producers must improve efficiency on broiler feed conversion (useless feed), and reduce excreta (pollutant) production. Additionally, producers must reduce water use, an input that will become increasingly scarce, restricting production in many regions of the world. In these areas, where animals will compete with humans for resources, there will be no room to feed broilers with a large nutrient specification. The only way to maintain production is to improve the understanding of precision nutrition so that producers can feed animals with low or no margin for error.

Feeding broilers of the future sustainable

Broiler production free of antibiotic growth promoters (AGP)

Producing broilers free of antibiotic growth promoters (AGPs) has been considered for many years. The first proposal on producing broilers AGP free came from Sweden in 1986. Initial reactions to the proposal focused on a loss of broiler production efficiency, wherein the cost of production would increase. After many years of research, however, these assumptions are no longer accepted in the industry. Societal concern in Europe promoted the development of research on non-antibiotic additives (probiotics, prebiotics, essential oils, organic acids, antioxidants, etc.) and a more efficient use of enzymes, which preserves gut health, with minimal or no reduction on broiler performance. Simultaneously, technical broiler advisers reinforced the implementation of management best practices, feeding and biosecurity care, all improving infection prevention and minimizing production inefficiency.

While the production of AGP-free animals is now an option in many countries, the speed of implementation varies. In 2015, the U.S. finally joined the European movement. The move to AGP-free started in 2010, when the Food and Drug Administration (FDA) called for a strategy to phase out production use of medically important antimicrobial products and to bring the remaining therapeutic uses under the oversight of a veterinarian. This had an important consequence. Food chain and supermarket enterprises accepted the challenge and began publicizing that the ingredients used in their products were AGP-free. Consumers picked up on the news, and the AGP-free movement kept growing. Today, reducing antibiotics in production remains an important innovation priority for nutritionists.

Ingredient analysis

Knowing ingredient composition, with the help of qualified laboratory support, is mandatory if the nutritionists want to formulate feed with a lean safety margin. Historical data shows that many nutritionists underestimate ingredient nutrient values, which does not guarantee better broiler performance. Instead, it means an incremental nutrient loss and a possible increase on pollution (nitrogen and phosphorus). With the progress of NIR technology, mills have no excuse for not having constant nutrient evaluation on their ingredients. Here are examples of proper nutrient end energy valuation and its benefits:

- Pirgozliev et al., in 2009, identified the importance of looking at the amylose:amylopectin ratio of different cereals (corn, wheat and rice) and how they can affect broiler performance.

- Zhou et al., in 2010, working with ducks, similarly observed that amylose:amylopectin ratio is one of the main factors that determine true metabolizable energy in corn, and can be used to predict the available energy.

These examples show that ingredients used in the diets are not just “commodities” when used in feed formulation, but important nutrient drivers of production. New technologies like “in-line feed formulation” are pushing the bounds of precision nutrition. The technology allows a NIR to be installed in the ingredients transportation line, before the mixer, which allows an immediate reading and consequent formulation and dosing, according to the nutrient composition of the ingredients that were read. This and other advancements are helping feed mills to deliver feed with exacting specification to produce better poultry, more sustainably.

Digestibility and phase feeding

The digestibility of the nutrients and energy vary in different production phases. For example, younger chicks are less efficient than older chicks. In addition, composition and digestibility of ingredients can differ in various years and global regions. Knowing these digestibility differences and correctly calculating the required ingredient composition for the various phases will be an important skill for nutritionists in years to come. Getting digestibility calculations, before feed formulation, means a lessened diet cost, better host digestive tract health and increased environment sustainability.

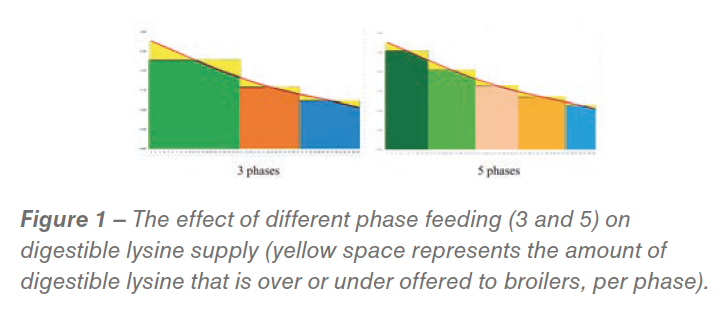

In addition to improving digestibility calculations, increasing the number of phases during production ensures less nutrient waste. For example, using five feeding phases, compared to three phases in broiler feeding, increases lysine delivery precision (Figure 1). Brewer et al. worked with three different genetic strains and fed broilers with three different diets (0-18, 19-32 and 33-40 days of age) or, after 19 days of age, phase-fed the birds, changing the diets every two days. Phase feeding, during the overall period (19 to 40 days of age) did not affect weight gain but improved feed efficiency on two of three strains and did not compromise the fillet weight in all strains. Phase feeding significantly reduced protein and amino acid consumption, making the cost of feeding cheaper than the conventional system. Similar results were seen when working with four different strains, phase feeding one group every two days, from 17 to 58 days of age. The main benefit of phase feeding was the reduction of production cost due to lower nutrient and energy consumption. These findings confirmed what was observed by Angel et al. Moving from four to six broiler phases (0 to 42 days of age) and supplementing the six diets with amino acids (lysine, methionine, threonine, isoleucine, valine, arginine and tryptophan), the nitrogen excretion was reduced by 40 percent when compared to the control proposal (4 phases).

The scientists are concern with the best use of nutrients and energy but, in the future, more research will be done using ingredient net energy instead of conventional metabolized energy, another method that will favor environmental sustainability.

Sometimes phase feeding is limited because of the feed mill structure. This new understanding of phase importance must be considered when a new feed mill project is developed and logistics are defined, so that the mill does not become the bottle neck of production.

Sex feeding

Generally, sex feeding is a controversial subject among nutritionists, hatcheries, feed mills, broiler production and slaughter plant managers. But, in the future, an increase focus on sustainability will require that all areas of production contribute logistically to improvement. The differences between male and female growth speed, body composition, nutrition requirement and behavior are sufficient to justify separate sex production. This strategy promotes reduction of feed cost and, most importantly, reduction of slaughter weight variability. In mixed-sex production, males will need to stay in the barns longer to push the weight up to a specific average body weight that cannot be achieved by females. That procedure can double body weight variability, making male feed efficiency worse and increasing mortality, because of the extra days in the barn. The Aviagen manual for broiler 308 (2014) and the Cobb manual for broiler 500 (2015) do not offer information on sex nutrient requirement differences. However, Aviagen (2014) suggests that in the case of using separate sex feeding, modifications of nutrients and energy requirements should be considered. Both manuals show differences in the speed of weight gain and feed efficiency of different sexes and they differ on nutrients and energy recommendations. Therefore, broilers of each of these strains require different feed and nutrients. These considerations were confirmed by Faridy et al. when they evaluated data research from Cobb and Ross strains. Using meta-analysis, they concluded that males require more lysine than females and there is a difference of lysine requirement according to the strain. Also, lysine requirement increases with the increase of crude protein in the diet.

Particle size and pelleting

The nutritionists and feed mill managers must look more to particle size and feed pelleting. Feed with larger particle size promotes better gizzard development, gastric motility and gastro duodenal reflux in poultry. It improves digestion and reduces the entrance of pathogens in the intestine. Large particles require less energy during feed apprehension, as birds require fewer pecks to ingest the same amount of feed and feed mills save energy from reduced grinding.

Broilers fed pelleted diets showed better performance than those fed mash diets, with improvement directly related to pellet quality. Poultry fed pellets have higher dietary density; higher feed intake; reduction of energy for consumption; better starch and protein digestibility and reduction of feed waste. Zang et al., in 2009, added that pellet improves intestinal function, as shown by increase in villi height and in villi height to crypt depth ratio. Most of these earlier findings were confirmed lately by Naderinejad et al., in 2016, who reinforced that coarse corn particle size and pellet diets improve gizzard development and function and improve the use of nutrients and energy that promote better broiler performance.

Additives-enzyames

Sometimes enzymes are wrongly called additives. They are proteins. They can improve digestion of nutrients and energy but also offer nutrients and energy to the host. New enzyme technology has been growing very quickly in the last 15-20 years and it will continue to do so in the future. In 1996, Cowan et al. said that this technology improves ingredient digestibility and nutrient absorption. Also, Penz Jr. and Bruno, in 2010, reinforced that enzyme technology reduces pollutant excretion in animal waste. There are many enzymes available to help the digestion of phosphorus, calcium, carbohydrates, proteins and lipids of diets offered to the animals, especially poultry and swine. However, enzymes will not always work with 100 percent efficiency because they are exogenous sources. Their efficient use will depend on correct technical decisions, correct mixing and substrate availability.

There is a vast wealth of information available describing different modes of action and different enzyme products and inclusions, and nutritionists should look at enzyme use as another way to make poultry production more environmentally sustainable. Even 10 percent improvement on enzyme-promoted nutrients and energy digestibility might reduce waste disposal and nitrogen and phosphorus pollution. In addition, with the appeal of producing AGP-free broilers increasing, gut health is more important than ever. It is well known that around 70% of poultry immune response is provided by digestive tract cell stimulation, and well-used enzymes have a unique, positive effect on broiler immune response from the gut.

From the Proceedings of XXV World’s Poultry Congress