It is essential that newly hatched poults are provided with the best possible starting conditions in brooding. This is a fundamental first step to ensure a healthy and balanced development to allow the poult to express its maximum productive potential for meat or eggs.

Management of temperature is essential in the early stages of a poult’s life and we must not forget how important the correct temperature is during the hatching, processing and transport of poults and how this can affect development. The newly hatched poult has a limited ability to regulate its internal body temperature because the thermoregulation system is not fully developed at hatch, and will only begin to fully develop around 4-6 days of age.

It is important to guarantee a temperature that keeps the poult in a thermoneutral zone, in which the poults are able to maintain their body temperature at a constant level without altering their metabolic rate and therefore focus on other factors of their growth, such as eating and drinking.

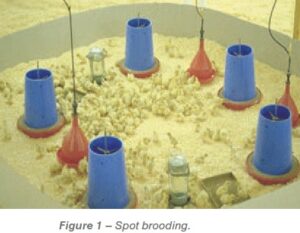

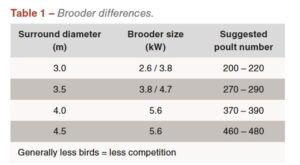

As poults start to grow, the management of temperature and environment changes completely. Over the years, techniques for turkeys have been fine-tuned into two particular methods. One of these methods is ‘spot brooding’ (see Figure 1). Spot brooding involves placing the poults in circles, each heated with a brooder. The number of poults placed and the size of the circles also vary in relation to the power of the brooders used (see Table 1). Another brooding method is ‘whole house brooding’. Poults are placed in houses without particular partitions and heated with brooders or heat blowers, where the poults can move freely throughout the available house space (see Figure 2).

Spot brooding involves placing the poults in circles, each heated with a brooder. The number of poults placed and the size of the circles also vary in relation to the power of the brooders used (see Table 1). Another brooding method is ‘whole house brooding’. Poults are placed in houses without particular partitions and heated with brooders or heat blowers, where the poults can move freely throughout the available house space (see Figure 2).

The temperature that we guarantee to the poults plays a fundamental role in the early stages of their life. In nature, the poult approaches the mother hen when it requires heat the most (after eating and sleeping for example). On farm we can only provide a substitute for the mother hen which is generally a light source or infrared rays.

This is particularly important in the case of ambient brooding with hot blowers or underfloor heating. The introduction of lamps, preferably infrared, fully satisfies this need from the poult by providing a source of light and heat that substitutes the mother hen as it attracts the poult at the opportune moments. This problem occurs to a lesser extent in the case of spot heating brooders because the brooder, whether gas or electric, becomes the mother hen, and the poults tend to approach or move away according to their needs.

With the addition of solar panels in many countries providing low cost electricity, we have seen an increasing use of infrared electric lamps (see Figure 3).

There are many positive aspects related to the use of these lamps, such as the reduced production of both CO2 and CO which can be a high risk with gas brooders due to poor management or functioning. The downside is that in general, these electric brooders are less powerful than gas options and therefore a greater number of lamps are required to achieve the same output. Another option is to use the electric lamps together with hot air blowers that create a “base” of the room temperature.

Many years ago, spot brooding in circles was used in almost all cases. Over time, with the increased search for cost reduction, the lack of labor and last but not least, the improvement of facilities and equipment available, the placement of poults in whole house brooding has become more common.

Speaking with the senior manager of the turkey division at Amadori in Italy – Dr. Falcioni quoted: “advancement has happened due to cost, labor and improvements which are even more apparent on large owned farms”. Dr. Falcioni took the decision to alter their brooding technique in Italy which has been defined as ‘corridor brooding’. Corridor brooding entails two wire fences parallel to the sides of the house, spread 3-4 meters away from each other and equipment and brooders are arranged inside this corridor (see Figure 4). The corridor can also be separated in several places to reduce the number of poults in each section (see Figure 5).  However, it is also evident that the labor costs for brooding this way are lower than the brooding with rings. The use of the “corridor brooding” has allowed Amadori to continue to use the gas brooders, each arranged in the same direction to avoid confusing the poults. In many cases the gas brooders are assisted by hot air blowers, (operating in the exterior of the house) which then creates the “base” of the ambient temperature (see Figure 6).

However, it is also evident that the labor costs for brooding this way are lower than the brooding with rings. The use of the “corridor brooding” has allowed Amadori to continue to use the gas brooders, each arranged in the same direction to avoid confusing the poults. In many cases the gas brooders are assisted by hot air blowers, (operating in the exterior of the house) which then creates the “base” of the ambient temperature (see Figure 6).

This transformation made it possible to provide the poults with a greater brooding surface and less need to intervene inside the partitions. Less foot traffic inside the ‘corridor brooding’, means this method keeps the area clean, as it uses the same principle as spot brooding with circles.

This transformation made it possible to provide the poults with a greater brooding surface and less need to intervene inside the partitions. Less foot traffic inside the ‘corridor brooding’, means this method keeps the area clean, as it uses the same principle as spot brooding with circles.

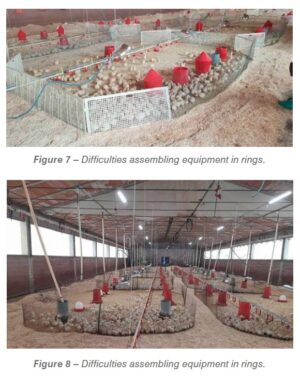

We are therefore faced with an intermediate modification, with savings in labor, but keeping the poults in a clean and thermo-neutral environment until the end of the first week or beyond if possible. Having said that, Dr. Falcioni argues, another important reason for this first development was the difficulty of using the new materials such as drinker and automatic feeders used in spot brooding.

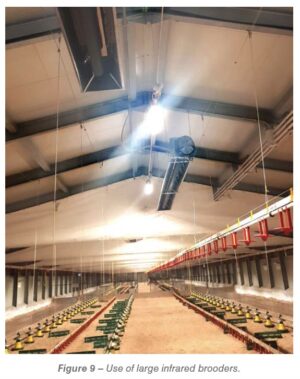

With this kind of equipment, to meet the bird’s requirement of feeding and drinking space, the circle must be cut according to one or even two lines of cup drinkers and automatic feeders, creating obvious difficulties in assembly (see Figures 7 and 8).  The next step was to be able to fully utilize the potential of the equipment that guarantees to meet the needs of feeder and drinker space. Houses were heated with large infrared brooders approximately 3 meters long, arranged 10 meters apart and 2.8 meters from the ground (see Figure 9). With these brooders, the infrared coverage is guaranteed for approximately 6 meters per side of the lamps (12 meters in total). In general, the thermostat is adjusted to 33 °C by placing it between two brooders and at a distance of about 1.5 meters from the brooders themselves. Poults are then guaranteed an optimum temperature and total coverage of the surface available to them. If the sheds are wider than 12 meters, nets can be used to prevent the poults from coming into contact with “cold” areas not covered by the infrared brooders .

The next step was to be able to fully utilize the potential of the equipment that guarantees to meet the needs of feeder and drinker space. Houses were heated with large infrared brooders approximately 3 meters long, arranged 10 meters apart and 2.8 meters from the ground (see Figure 9). With these brooders, the infrared coverage is guaranteed for approximately 6 meters per side of the lamps (12 meters in total). In general, the thermostat is adjusted to 33 °C by placing it between two brooders and at a distance of about 1.5 meters from the brooders themselves. Poults are then guaranteed an optimum temperature and total coverage of the surface available to them. If the sheds are wider than 12 meters, nets can be used to prevent the poults from coming into contact with “cold” areas not covered by the infrared brooders .

With this type of brooder it is possible to brood the poults along the entire length of the house, limiting the need for partitions as much as possible. This system guarantees the poults a larger feeding and drinking area, whilst being able to exploit the potential and numbers of the automatic equipment. It can guarantee up to, and exceed 2.5 cm of feeding space and 1.5 cm of drinking space per head.

With this space available, two extremely positive results are obtained; firstly the poults find feed and water quicker, therefore increasing the level of uniformity in the flock. The second is that with more equipment and extra space available for the poults, the litter under drinkers and feeders remains drier in comparison with conditions in brooding rings. It is important to note that there is a tendency to also introduce manual equipment (especially feeders) which will in any case be gradually removed within 4-5 days of life.

With this space available, two extremely positive results are obtained; firstly the poults find feed and water quicker, therefore increasing the level of uniformity in the flock. The second is that with more equipment and extra space available for the poults, the litter under drinkers and feeders remains drier in comparison with conditions in brooding rings. It is important to note that there is a tendency to also introduce manual equipment (especially feeders) which will in any case be gradually removed within 4-5 days of life.

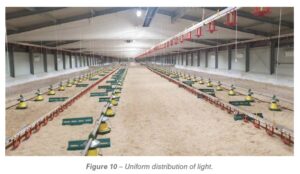

Another important factor to brooding is the lighting. Growing in popularity are the new structures of a single dimmable lighting line. The surface of the lamps consists of a lens that ensures uniform distribution of light intensity (see Figure 10).

This single line of lighting is very important in summer cycles. In the case of hot days, it is necessary to reduce the functioning of the brooders as much as possible. If necessary, by lowering the light intensity, the poults are still encouraged under the lamp guaranteeing the “mother hen” effect.

This single line of lighting is very important in summer cycles. In the case of hot days, it is necessary to reduce the functioning of the brooders as much as possible. If necessary, by lowering the light intensity, the poults are still encouraged under the lamp guaranteeing the “mother hen” effect.

In conclusion, the brooding method described of “whole house brooding” represents one of the best available for the following reasons:

- having a perfect infrared coverage, then a controlled temperature and uniform lighting in the house will help substitute the ‘mother hen’ to the poults;

- the space allows increased feeding and drinking availability as well as better quality of litter;

- this system will help with high levels of uniformity, reduce mortality levels and ensure poults express their genetic abilities as it has been said, only spot brooding could guarantee this;

- last but not least it reduces labor costs.

Generally “whole house brooding” is being used more and more, especially with commercial flocks, and represents the future of brooding. When using “whole ambient brooders” by hot blowers or under floor heating, we strongly suggest the use of infrared (electric or gas) lamps or stoves to respond better to the need of poults in easily identifying a surrogate for the mother. The importance of infrared in the brooding period is evident and its correct use can really make it easier to overtake this important phase of the poult’s life. Nevertheless, it is also important to continue to develop better methods to meet the needs of poults and at the same time reduce production costs.