Animal health is an important factor to consider, as any disease outbreak can potentially have drastic economical consequences. For this reason, planning and preparing an injection campaign should be done carefully.

Planification

When preparing a campaign, consider appropriate animal age and time in the year to run it. Select adequate injectable product and carefully follow manufacturer’s instructions to reconstitute the vaccine. Because of limited shelf-life of opened vials, prepare and mix only the quantity required at the time.

Instrument preparation

Unless previously autoclaved, both syringe and feed tubing must be cleaned (aspiration of boiling water). A sterilized instrument can be used straight away. Disinfectant or chemicals must not be applied, as they may destroy vaccine efficiency. Select the best appropriate syringe model and capacity and pay attention to adequate needle choice.

Needle selection

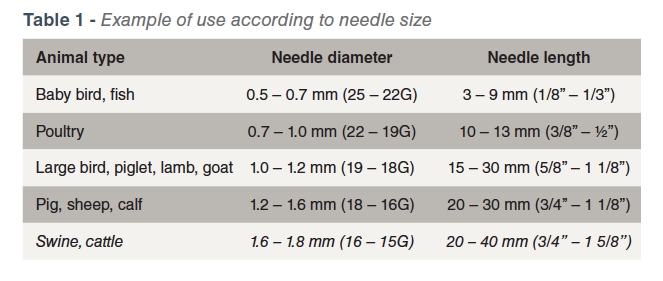

Prefer quality material (high mechanical resistance) and choose appropriate length and gauge in accordance with animal size/age and vaccine type. Select smallest possible needle diameter (gauge) to minimize tissue damage. Change needle if bent, dirty, worn or Blunt edged. The Socorex safety needle packaging is intended for operator’s protection, avoiding hand / finger injury when handling.

A superior syringe programme

Socorex Isba SA is a Swiss manufacturer of self-refilling injection syringes with spring-loaded plunger and three-way valve system. Simple conception, perfect balance and ergonomic design provide for ease of use, operator comfort and fatigue free fieldwork. The syringes are intended for mass vaccination of poultry, swine, cattle, fish and small laboratory animals. They are used and recommended by many pharmaceutical companies in the animal health market. Customers appreciate its efficiency and reliability, the simple syringe conception, perfect balance and ergonomic design.

Cleaning-up after vaccination

Once the campaign is over, operator must rinse, disinfect, clean and dry the injection syringe according to manufacturer’s guidelines. Single-use and worn-out needles must be disposed of in an appropriate safety container. Store re-usable equipment in adequate clean and dry location to prevent risk of corrosion. All vaccines, diluents and any other biological sensitive materials must be stored in cool and dark place. Prefer a locked place to prevent access to unauthorized persons.

Observing rules and legislations

For traceability purpose, always keep track record of all vaccination parameters (based on farm’s or company’s procedures). As example, date of injection, operator’s name, animal ID, vaccine type/name/ manufacturer and volume, vaccine lot and expiry date.

It is recommended to fully respect applicable local and national laws. Mind permanent or temporary rules/guide lines issued by MOA, animal directorates, professional associations, etc. and remember that safety of farm personnel and consumers comes first.

Combining a good planning, the use of a first class self-refilling syringe for highly professional work and respect of present rules and legislations, is the most efficient way to run successful injection campaigns.