All who work or visit poultry farms must adhere to the guidance of the farm management when it comes to biosecurity protocols.

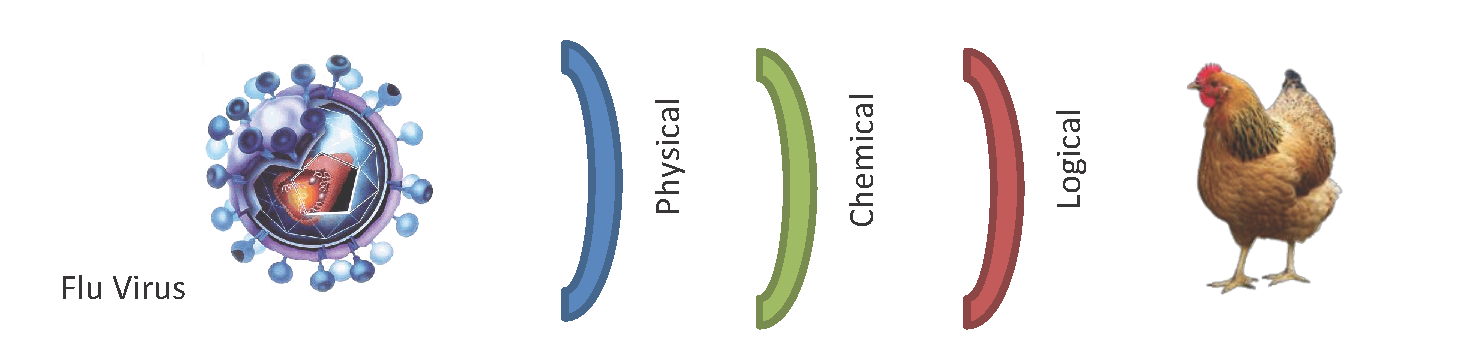

There are three basic ways of providing biosecurity barriers 1) physical barriers, as when using coveralls or boots, 2) chemical barriers as with the use of disinfectants, and 3) logical barriers that keep out of situations that lower exposure. The logical barriers could be the method of using age and disease status for planning visits to farms, and self-quarantine of animals who are suspect of disease.

In order to disinfect properly, cleaning must be the first step. If left dirty, the application of a disinfectant may not work. Chemicals such as Chlorine compounds do not work well in dirty environments. So, in essence a dirty object that is disinfected is still considered “dirty”. Visible dirt, biofilms, and any other material should be removed before the disinfection step. Remove any visible dirt from the object manually if possible.

Select a good foaming detergent in water and begin to wash the object. Use a brush to rub the soap into the surface of the object. This action does two things: first, it helps the soap surround the dirt particles and lift them off the surface. Secondly, scrubbing helps disrupt cell walls and helps break up bacteria. Foaming the soap adds some help in floating dirt off in hard to reach surfaces such as ceilings and when spraying the soap on surfaces. Rinse well all soap as the dirt is encased in the soap film (colloidal solution) and will be removed in the rinse water. Then, apply the disinfectant at the proper dilution to the object and wait the required contact time if listed in the instructions before final rinse with clean water or return to service. Knowing the contact time is important especially when C&D of moving objects, such as vehicles and boots. The contact time allows for the disinfectant to do its job to break up the virus or bacterial cell. An alcohol based disinfectant needs time to dry as desiccation is a major mode of killing / breaking up bacteria. Contact time can be lengthened by fine misting or foaming the agent onto the surface. Be sure to maintain stock of soaps in the right storage environment as freezing or high heat may deactivate their activity.

In so far as disinfectants there are a few choices but fewer than what is available to conventional production. Consult the OMRI guides or online for changes to the approved list of agents. Be sure to read and understand the product labels of all products you intend to use and keep copies of labels or MSDS sheets for certifying audits as required by your state certifying body.

One thing to remember as you use a disinfectant is to use the right concentration for the job at hand. For example the amount of bleach for sanitizing water is much different from disinfecting surfaces such as stainless steel. And, as you use a new product beware of activity between the disinfectant solution and the materials in comes into contact. Some products have been known to warp or soften plastics at high concentrations or prolonged contact times.

Some of the common products used for disinfection in organics are:

- Chlorine Compounds: Sodium Hypochlorite / Regular bleach, (not the scented, color safe, or other compounds) is the standard for clean non-porous surfaces. Residual chlorine should not exceed 4mg/L (4 ppm) when used as a water sanitizer. When using at higher concentration a flush rinse may be needed to reduce residuals to safe levels. Chlorine Dioxide is another product that could be used, but residual levels for water is limited to 0.8 mg/L (0.8 ppm) of activity. Not for use with heavy soiled materials.

- Acids: These compounds break down cell wall structures. Acetic Acid (Vinegar, 5% acid) is commonly found, but higher concentrations can be obtained if used for topical disinfection. Non-synthetic based products, such as cider vinegar is desired for use. Phosphoric Acid can be used so long as there is not contact with livestock or land in organic production. Higher concentrations of these acids can be aggressive / caustic to some materials.

- Iodine: Potassium Iodide, and acidified elemental iodine are used as surface disinfectants. Check brand labels for clearance with certifying body. These compounds can stain certain materials they are applied to.

- Hydrogen Peroxide is used as a water treatment as well as a surface sanitizer. Hydronium ion, and oxygen is produced with its degradation. Be mindful of the initial solution concentration, as dilution may need to be made from a concentrate. These compounds can be corrosive at times with certain metals. Check label for proper use and dilution for the intended applications. Not for use with heavy soiled materials.

- Alcohol: Isopropyl Alcohol at higher dilutions are effective in drying and breaking down bacterial cell walls. Mostly used in limited applications and for disinfecting hard surfaces topically. Isopropanol, and Ethanol can be used, according to label guidance. These compounds can be aggressive on some synthetic rubbers and plastics.

As sanitation products are selected, you may wish to rotate between two or more products periodically. This will help reduce the resistance of the bacterial and other germs on the farm. When tied with good cleaning techniques the load of germs on the farm can be minimized and the spread of disease forming agents can be achieved. This then forms the basis of good poultry farm operational biosecurity.

From the Proceedings of the 2018 Midwest Poultry Federation Convention