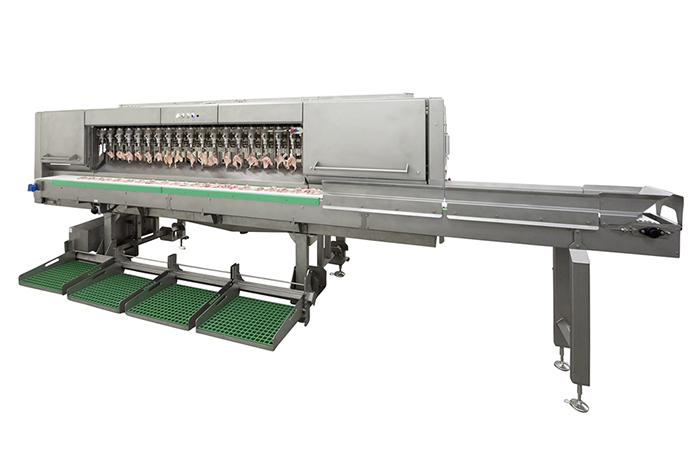

Precise and automatic thigh deboning with unrivalled productivity

The Meyn TDS Thigh Deboning Solution M 1.0 acts as an advanced and standalone new system for poultry producers worldwide. The carousel principle enables market-leading productivity and there are three models available, with capacities ranging from 3600 thighs per hour to 7200 thighs per hour (or 120 thighs per minute).

“The thigh deboner is an important new addition to Meyn’s range of deboning systems”, says Jeroen Bohm, Product Manager for Meyn Deboning Systems. “As a precise and highly efficient automatic system it reduces labor costs by 35% relative to competitive systems, while producing thigh fillets with an outstanding level of presentation.”

The thigh deboner is suitable for fresh and matured anatomical thighs, processing both left and right thighs with no handling prior to production. It is designed for chickens with a weight of approximately 1,700–5,100 gram (3.9–11 lbs), thus anatomical thighs with skin on that weigh 125 to 375 gram (0.28–0,8 lbs).The system incorporates a number of sophisticated deboning actions, including the deskinner, and separation of the kneecaps from the fillet. This minimizes the risk of bone fragments in the fillets and ensures that 86% of the meat is processed boneless. It also eliminates the need for trimming, further reducing labor costs. The system also separates the thighbone – including kneecap – from the fillet while the oyster muscle remains firmly attached, enhancing presentation quality. If desired, the system can be fitted with an integrated de-skinning module to produce skinless fill.

For further information: www.meyn.com