The robotised picking and packing of EggsCargo pallets and dividers has really taken off in the 18 years since the introduction of the EggsCargoSystem. There are now many companies around the world specialising in this branch of automation.

Because the various robots developed for this task are not all able to work to the same level of accuracy, a situation may arise where the stacks of trays cannot be placed within the gutter dimension of the divider. The difference may only be a matter of millimeters, nevertheless this can obviously lead to highly undesirable situations.

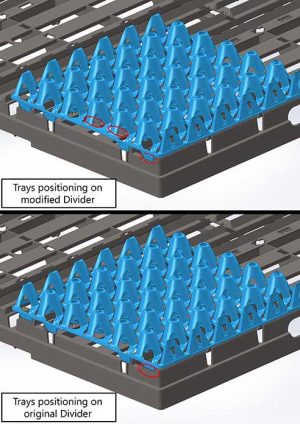

At Twinpack they have therefore decided to modify the EggsCargo Divider. As it can be seen from the picture, they have removed the stoppers from the guide slots on either side of the divider, relocating these to the center of the guide slots. This creates a few millimeters of space for the stacks of trays, which solves the situation users have been facing in some cases.

It is extremely important that the modified divider is compatible in all respects with other EggsCargo dividers on the market.

“We have tested the modified divider in use with the most common types of robot in use, and as far as we have been able to determine, it will not be necessary to modify existing robots. We also see no need to modify the working method for manual processing. The stack of trays will be restrained by the new stoppers, as was the case in the former situation.

We are convinced that this new generation of EggsCargo Dividers will be an even better match for our customers’ requirements. The suppliers of robots will also welcome this development, as it will greatly simplify the adjustment of robots for use with the EggsCargoSystem.

Our hope is that the ongoing development of our EggsCargoSystem on behalf of our customers will allow us to continue to live up to our promise to be the world’s most reliable system“, commented Jacco Wagelaar, Twinpack Special Products B.V. Managing Director.