Turkeys spend their life in close contact with litter material. The aim is to establish and maintain good, dry litter conditions and an environment free from dust to reduce footpad dermatitis, respiratory stress and carcass downgrades.

Whilst health, nutrition and genetics play important roles in achieving good litter quality, there are many practical management techniques to control litter moisture content to promote bird welfare and achieve good commercial performance.

Management factors influencing litter quality

Turkeys are responsible for most of the water in a poultry house. For every kg of feed a turkey eats it will drink approximately two kilograms of water. Most of this water ends up in the air or litter of the house.

- Approximately 45% of the water is exhaled into the air as water vapour.

- Approximately 55% is deposited into the litter in the form of faeces.

- Litter humidity is a function of ambient air humidity.

- The ideal air humidity inside the shed should be between 50 & 65%.

Other management factors include:

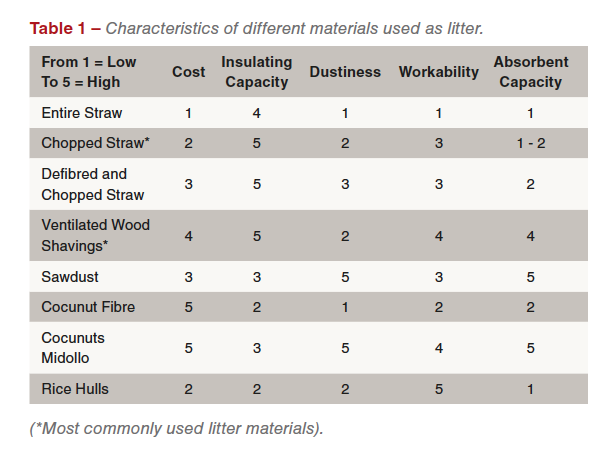

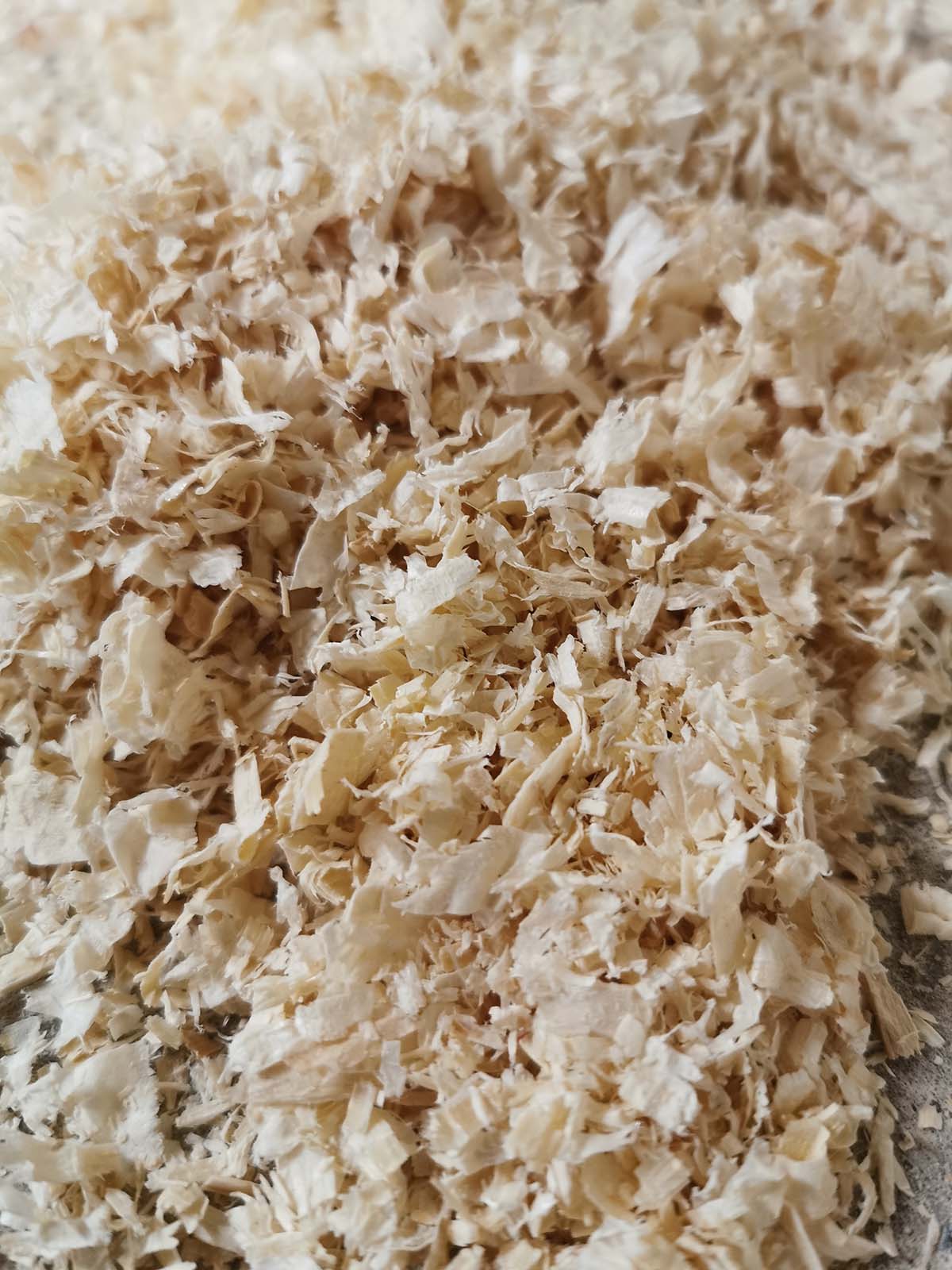

- Raw materials: Good litter materials should be dry, absorbent, and friable, provide insulation and be free from contaminants. Wood shavings and chopped straw are commonly used litter materials for turkeys. A comparison of litter materials is shown in Table 1.

- Litter depth and floor insulation: Fresh litter should be used for each crop to prevent re-infection by pathogens. When using wood shavings, litter depth should be at least 6–8 cm for summer placements and 10 cm for winter placements. Where underfloor heating is used, litter depth can be reduced. Litter should be spread evenly throughout the house and smoothed to level within the brooding rings.

- Stocking density: National laws must be observed. It is important not to exceed the number of birds the housing quality, the climate and local management conditions may tolerate.

- Temperature and humidity: Litter humidity can be managed by modifying house temperature, heating, ventilation rate, addition of new litter and spray cooling systems.

- Ventilation: Ventilation systems need to be managed to be even throughout the house. Air entering the building should arrive warm and dry on the turkeys and litter.

- Lighting: An even light distribution ensures a good spread of the turkeys, helping to achieve even litter quality. The correct light intensity will stimulate bird activity and encourage them to work the litter.

- Drinker management: Use the correct number and type of drinkers. Set drinker height and water level correctly.

Litter management procedures

It is important to avoid the litter becoming wet and caked in the first week of life. The objective is to have the bird’s feet completely clean and dry. This can be achieved by:

- Routinely moving feeding and drinker equipment to different positions if possible.

- Remove wet or caked litter and move and mix up the remaining litter.

- Adding fresh litter material and mixing with the older litter.

As the birds get older, the management of the litter must continue as a routine:

- Raise the lines of feeders and drinkers as the turkeys grow.

- Work the litter often (i.e. every day or every time there is a need) to avoid the formation of crusty or wet areas especially around drinker and feeder lines or add new litter material.

- Wet areas of litter means that the intervention has come too late and regular litter management must become more frequent.

Drinker management

- Have the right number and kind of drinkers.

- Set the correct height of the drinkers (for bell drinkers this should be at the shoulder level of the birds).

- Set the right level of the water in the drinkers (birds should drink without problems and not be required to spend too much time at the drinker to be satisfied).

- Clean and disinfect the drinkers often.

- Move the drinkers regularly (bell kind) avoiding the formation of typical “donuts”.

Management of nipple type drinkers

The height of the drinker lines should be set correctly:

- Not too low as birds may move or damage the drinkers with their body.

- Not too high as birds will rely too much on the plate and cause water leakage.

- Be aware that the slope of the floor in the shed can affect pressure and water distribution. The drinker lines must be level even if the floor is not.

- Ensure the lines are set the correct distance from feeders and lateral walls (minimum 2 metres).

Control ventilation

Optimal management of the ventilation system through heater, fan and inlet adjustment will remove excess moisture, ammonia and dust and provide an environment in which litter can be managed and the health of the turkey’s feet and respiratory system can be enhanced.

Dust

Litter can sometimes create problems associated with high levels of dust. This is quite typical in summer or even in specific areas during winter where the humidity can be very low. At these times:

- Choose the right litter material. Sawdust can be very dusty, but straw can reduce it.

- Cool the turkeys using water spray systems, which helps to control dust and increase humidity.

- Adjust ventilation; an excess of ventilation causes a decrease of environmental humidity (and of litter moisture), with a consequent increase in the formation of dust.