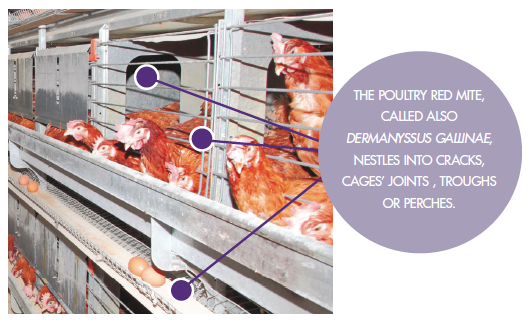

In poultry industries one of the most widespread ectoparasites is certainly the Dermanyssus gallinae, better known under the name of red mite. Globally, the presence of the Dermanyssus gallinae is widespread.

In Italy, for example, red mite infested farms exceed 80%, and in other countries the percentages are similar. Indeed, in Europe, the average number of infested farms is around 75% with the percentage being less in northern areas such as the Scandinavian countries where their climate, greatly attenuates the spread of mites.

The Dermanyssus gallinae spends the major part of its lifetime off the host seeking “refuge” in the cracks in buildings, in the joints of cages, under the rims of feeders or on perches etc., to then exit, especially during the night hours, to pounce on the dormant birds. The aim is to take on as much “blood meal” as possible which is indispensable for the ripening of eggs in the wombs of the females. The mite bites cause disorder and itching in the hens and induces a situation of chronic stress. This results in anaemia, decreased appetite and weight resulting in a decrease in productive performance. The altered physiology of the birds, if not mitigated, translates into a decrease of 10 to 15% of eggs laid.

Additionally, there is an increase of embryonic mortality in hatching eggs and a decrease in weight in table eggs. Among the most prominent features of these pests is their ability to survive in a fasting condition for prolonged periods. Also outstanding is the speed of their biological cycle under optimal conditions. In fact, in a matter of ten days or just a little more, the mite finishes its development and then after mating lays its eggs ready to hatch on the body of the birds. Temperature and high relative humidity, are among the main parameters that favour the development of the parasite. In the intensive farming of today temperature and relative humidity are deemed optimal conditions for bird welfare.

It is necessary to intervene in a targeted way against this most important sore for the poultry sector. In this sense, Baggy® is a very well formulated solution aimed at making the parasite vulnerable throughout its entire production cycle by acting directly on surfaces thereby sanitizing them. Baggy® performs a dual action as it thoroughly cleanses the surfaces and reduces the total

It is necessary to intervene in a targeted way against this most important sore for the poultry sector. In this sense, Baggy® is a very well formulated solution aimed at making the parasite vulnerable throughout its entire production cycle by acting directly on surfaces thereby sanitizing them. Baggy® performs a dual action as it thoroughly cleanses the surfaces and reduces the total  microbial count in the environment. Diluted in water and uniformly applied, Baggy® works quickly removing all the dirty material that are gathered by the mites in order to form nests and establish their colonies. Even after a few hours of application, the mites lose contact with the surface of the cages. These surfaces will appear visibly sanitized creating protection for the entire supply chain. Before Baggy® was launched in the European and world markets the effectiveness and safety of the product was approved by the accredited institutions and judged the “ideal” product in the struggle against red mite in chickens throughout the whole production cycle while fully respecting bird welfare and their environment.

microbial count in the environment. Diluted in water and uniformly applied, Baggy® works quickly removing all the dirty material that are gathered by the mites in order to form nests and establish their colonies. Even after a few hours of application, the mites lose contact with the surface of the cages. These surfaces will appear visibly sanitized creating protection for the entire supply chain. Before Baggy® was launched in the European and world markets the effectiveness and safety of the product was approved by the accredited institutions and judged the “ideal” product in the struggle against red mite in chickens throughout the whole production cycle while fully respecting bird welfare and their environment.

Time optimization and maximum application efficiency thanks to the right equipment

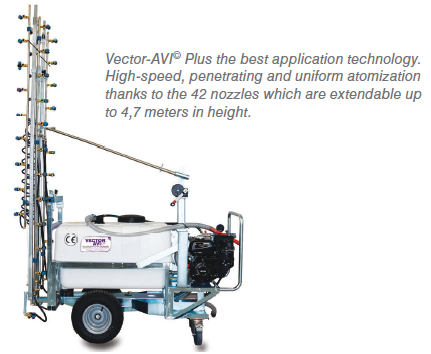

In addition to their specific products to control red mites and to sanitize the environment Newpharm can also supply effective and cutting edge technology and application equipment for the deep disinfectation of animal husbandry facilities. Among their product range is the excellent Vector-AVI® Plus. This innovative equipment developed exclusively by Newpharm, based on the experience of pest control professionals, does an excellent job in the spraying of of miticides, insecticides, detergenis, vaccinations and disinfectants.

In addition to their specific products to control red mites and to sanitize the environment Newpharm can also supply effective and cutting edge technology and application equipment for the deep disinfectation of animal husbandry facilities. Among their product range is the excellent Vector-AVI® Plus. This innovative equipment developed exclusively by Newpharm, based on the experience of pest control professionals, does an excellent job in the spraying of of miticides, insecticides, detergenis, vaccinations and disinfectants.

The high power delivery spray, the excellent quality of the component parts and the excellent manoeuvrability, make the Vector-AVI® Plus unique.

The high power delivery spray, the excellent quality of the component parts and the excellent manoeuvrability, make the Vector-AVI® Plus unique.

The machine is equipped with two vertical bars with telescopic adjustment (a solution adopted also in the nautical field) and has directional cone nozzles, for maximum precision and flexibility during use.

Vector-AVI® Plus, thanks to its design features is adaptable to all situations and comfortably reaches the highest of cage layouts ensuring maximum spraying penetration and optimization of application times.

Via Tremarende, 24/B 35010 S. Giustina in Colle (PD) – Italy

Tel. +39 049 9302876 – Fax +39 049 9320087

info@newpharm.it – www.newpharm.it – www.progettoacaro.it