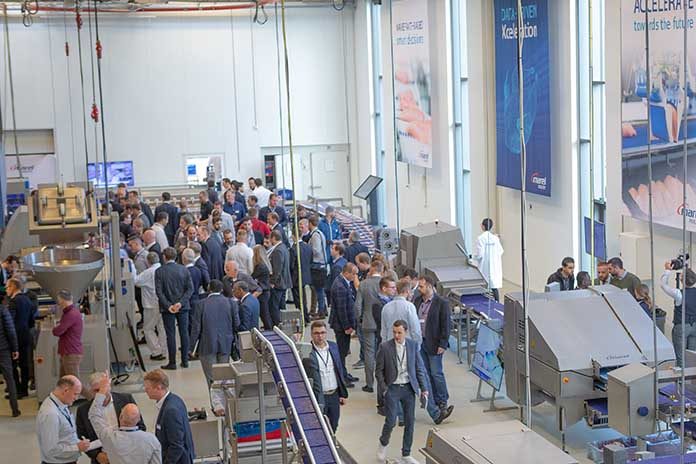

Marel’s third Poultry ShowHow in Copenhagen on 14 November 2019 put the focus on ‘Data-driven Xceleration’, representing the future of digitally controlled poultry processing. The biennial event attracted more than 120 customers from around the world.

Right on target

The event centered around the theme ‘Data-driven Xceleration’. This message was very well received as all customers understand that the future of poultry processing will unfold in the digital area. Roger Claessens, EVP of Marel Poultry, said, “The data control opportunities we showed for primary and secondary processing were right on target. All our customers here feel connected to the theme Data-driven Xceleration, even processors not working at the highest capacities. For them, this is a speck on the horizon.”

Keynotes

All activities during the ShowHow referred to the digital control of processes in the poultry plant. In fact, one of the aims of the event was to show how different people in the plant are working with their own part of the software platform; a technical manager needs different dashboards than a quality manager or a production planner. Two showrooms clearly outlined these software ‘personas’.

The opening keynote clarified the difference between ‘regular’ OEE (having insight) and IMPAQT (knowing how to improve the process). Further lectures featured subjects such as Added value with convenience food, Fillet Value Optimization, Q-Wing and Optimizing production planning, all with the shared component of software-controlled, data-driven processes.

The conclusion of the event was made by Rabobank’s Nan-Dirk Mulder. He presented a global overview of the poultry market, signaling key trends in this fast-changing industry.

Hands-on experience

The demo hall featured an elaborate fillet handling solution, ready to process real breast caps. Starting with an AMF-i breast cap filleting system, various modules in the line, including SensorX, I-Cut 122, SmartSplitter and RoboBatcher, processed the fillets. This data-driven, connected configuration clearly highlighted Marel Poultry’s technological qualities and digital capabilities. Other presentations in the demo hall involved Multihead Weigher Medium, Compact Grader and a complete Convenience Food Line, including RevoBreader. The running lines made the demo hall look like a real one-day show plant. As customers really took the fillets from the belt to inspect them, the hands-on experience was more intense than ever.