The consequences of biofilm in the drinking line are generally underestimated, while optimal production results mainly depend on good drinking water quality.

Hygiene is an important part of achieving optimal production results. Many poultry farmers have strict protocols to prevent their poultry from getting certain diseases. These protocols mainly apply to the feed supply and visitors in the form of protective clothing. However, drinking water can also pose a risk if it is not properly maintained. Something that is unfortunately often overlooked by poultry farmers.

Water is one of the most common and purest compounds worldwide. But water sources are dynamic and constantly changing. Floods, drought or agriculture and industry all affect these sources and therefore the composition of water.

We notice that the importance of clean and fresh drinking water is often underestimated. There are several factors that influence the health of the birds, but drinking water really is the most important. Excellent drinking water quality is essential for your poultry to perform optimally.

A study conducted by the Animal Health Service (GD) clearly shows where things go wrong and what the consequences may be:

- 34% of all drinking water from the nipples is of moderate / poor quality.

- On average, poultry farmers spent 100 times more on food than on water.

- An average contamination with fungi and yeasts costs a farm with approx. 30,000 laying hens approximately EUR 12,000 per year.

- An average bacterial contamination costs a farm with approx. 29,000 broilers around 2,100 euros per round.

A closed drinking system

Many poultry farmers have switched to closed drinking systems to reduce the risk of contamination from dust, feed, feathers and litter. The problem is that they are no longer aware of the quality of the water. Previously, the open water systems were regularly cleaned, so you were constantly reminded how dirty the drinking water could become. But with a closed drinking system this is no longer visible. However, that does not mean that the water is not contaminated with bacteria, fungi and minerals, which flourish in a slowly flowing and nutrient-rich water supply.

Whether the water quality is good or bad depends on the harmful substances in the water. These substances determine the taste, hardness and PH value of the water and thus also whether the water quality is good enough for the animals.

The formation of biofilm

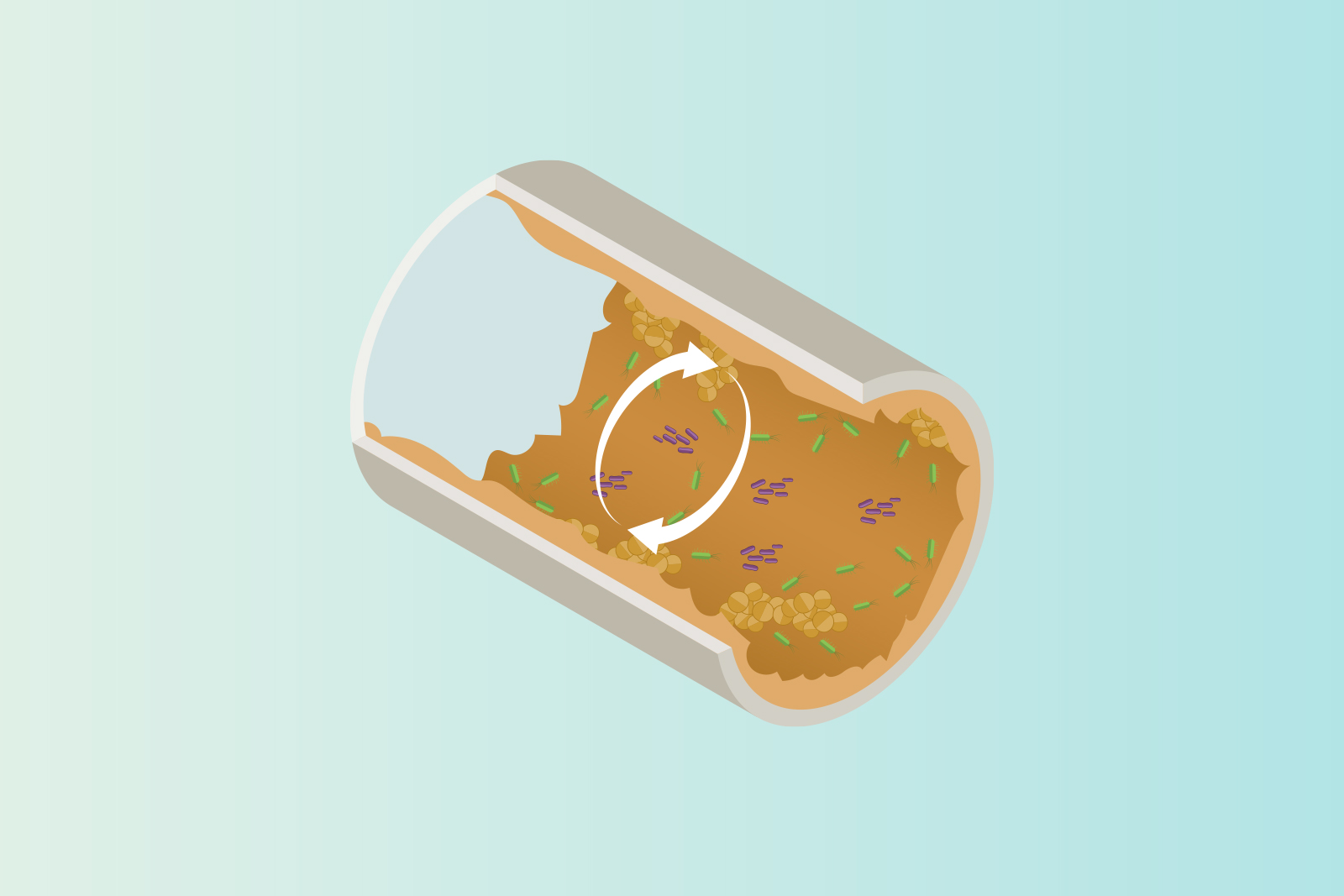

Another major problem that can form in a closed drinking system is biofilm. Lime, iron and manganese, among other things, cause a hard structure on the inside of the drinking line. This hard structure ensures that (especially) drug residues can easily adhere. The sugars in these drug residues are in turn a perfect breeding ground for bacteria and fungi. This creates a slimy layer on the inside of the drinking line called biofilm. The biofilm then protects the harmful micro-organisms against antibacterial agents.

The water flows slowly in closed drinking systems, which means that biofilm can develop very quickly. Too warm water can also be an ideal food source for biofilm. Therefore, it is also very important to monitor the formation of biofilm and take immediate action as soon as this happens.

What are the consequences of biofilm?

The presence of biofilm in the drinking lines can have serious consequences. Among other things, the effectiveness of medicines and vaccines that are administered via the drinking line can decrease considerably. In turn, this can have a negative effect on the final production results.

Once biofilm has formed, it can be quite difficult to get the drinking lines clean again and to keep them clean. Even if you manage to remove the biofilm, it can return in about three days. That is why it is so important to prevent the formation of biofilm in the drinking lines.

But how do you prevent biofilm?

One of the easiest ways to prevent the formation of biofilm as much as possible is by routine flushing. In addition, it is important to flush and clean the drinking lines thoroughly after using additives or medicines. This washes away the main food sources for bacteria.

It is also important to thoroughly flush and clean the drinking system between rounds. This is especially important if the lines are not used for a longer period of time.

Automatic flushing

An automatic flushing system is an effective solution to flush the drinking lines regularly and easily, thereby preventing the formation of biofilm. The computer controls the entire flushing process following a personalized program. You decide the frequency with which the computer should flush the system, which lines should be flushed and how long the flushing should last.

In addition, the system uses the information it receives from sensors in the drinking lines. These sensors measure the water temperature and the build-up of biofilm. As soon as an anomaly is detected, the flushing computer receives the signal to automatically flush the drinking lines.

A maximum number of flushings can be set to prevent excessive flushing. When this maximum is reached, the computer gives a signal to indicate that further action must be taken.

Achieve optimal results

Poultry farmers are generally very conscious about the quality of the feed, but the influence of poor drinking water quality is often underestimated. However, in order to achieve optimal production results, the quality of the drinking water is also very important. This means that you have to be very conscious about maintaining the drinking system. An automatic flushing system is the ideal solution, because the program can regulate the flushing fully automatically and thus also prevents the formation of biofilm in the drinking lines.