A new circular economy model for the poultry market thanks to an innovative technology based on two patents for the transition to smart agriculture.

Rosalino Usci, PhD – Mechanical Engineer, Michele Marcantoni, PhD – Mechanical Engineer

Chief Executive Officer and Founding Partner of 3P Engineering, authors of two patents of CHIMERA “CHickens Manure Exploitation and RevAluation”

Rising costs of raw materials, soaring fertilizer up to 170 percent and increasing energy prices, are three trends that are destabilizing the agricultural market. Research and innovation can provide the answers to create virtuous green models, also from the management point of view, accelerating the ecological transition towards “smart agriculture”. A new agricultural paradigm which combines traditional practices with new digital and technical solutions, increasing the efficiency of the farm.

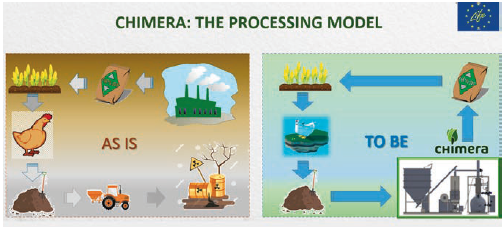

“CHIMERA CHIckens Manure Exploitation and RevAluation” is a project of the European LIFE program (GA n. LIFE15 ENV/ IT/000631), an example of virtuous model to respond to eco-sustainability needs (i.e. organic waste recicling) by implementing the principles of circular economy: it consists of a new technology that allows the enhancement of chicken manure by transforming it into fertilizer and energy.  Chicken manure, from animal by-product to resource

Chicken manure, from animal by-product to resource

Chicken manure is a by-product that can be also a resource due to the significant presence of nutrients; at the same time, it contains ammonia (NH3), dinitrogen (N2), nitrous oxide (N2O) and nitrate (NO3) in high quantities. For many years, chicken manure has traditionally been sprinkled on agricultural soils, used directly as fertilizer, but the EU Nitrates Directive (1991) regulated and limited its practice as it alters the balance of soil and water, and for the impact in the air with a high dispersion of ammonia (NH3 – greenhouse gas).

Therefore, chicken manure must be managed, entailing storage costs due to its polluting and odorous emissions. In Italy, the agricultural sector accounts for 94% of national ammonia emissions (and in particular, storage accounts for 29.2%, spreading for 20.7% and synthetic fertilizers for 14.6%); the weight of NH3 emissions from poultry is equal to 12.1% of the total of animal categories (Source: ISPRA – Higher Institute for Environmental Protection and Research, 2020). In this context, it has to be highlighted the key target of the European Union, which envisages a reduction of greenhouse gas emissions (compared to 1990 levels) by 55% for 2030.

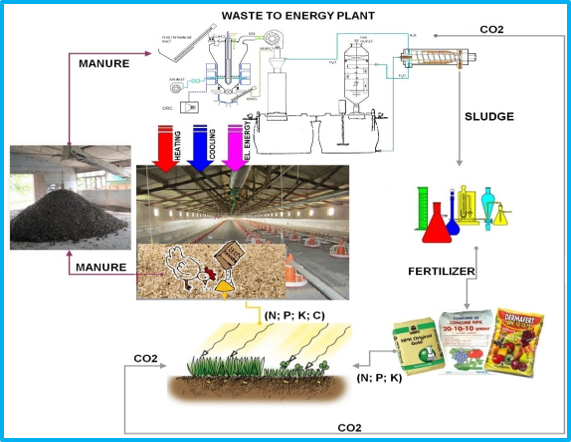

CHIMERA aims to reinvent the process of using chicken manure by eliminating its polluting power to instead enhance all its properties: the new technology uses a plant allowing farmers to reduce storage costs and avoid the dispersion of nitrogen compounds in the environment, recovering them through the production of a valuable NPK fertilizer. Furthermore, the energy potential of the chicken manure is exploited thanks to a waste-to-energy through combustion, guaranteeing energy recovery. The new solution therefore allows to improve the efficiency of production by using a by-product thanks to the heart of its innovation: the combustion process of the CHIMERA system is based on two patents developed by an Innovative SME, 3P Engineering, already author of 31 patents, based in Chiaravalle (Ancona, Italy), and accredited “Testing Laboratory” (Accredia Lab n. 1537 L, UNI CEI EN ISO/IEC 17025:2018).

CHIMERA aims to reinvent the process of using chicken manure by eliminating its polluting power to instead enhance all its properties: the new technology uses a plant allowing farmers to reduce storage costs and avoid the dispersion of nitrogen compounds in the environment, recovering them through the production of a valuable NPK fertilizer. Furthermore, the energy potential of the chicken manure is exploited thanks to a waste-to-energy through combustion, guaranteeing energy recovery. The new solution therefore allows to improve the efficiency of production by using a by-product thanks to the heart of its innovation: the combustion process of the CHIMERA system is based on two patents developed by an Innovative SME, 3P Engineering, already author of 31 patents, based in Chiaravalle (Ancona, Italy), and accredited “Testing Laboratory” (Accredia Lab n. 1537 L, UNI CEI EN ISO/IEC 17025:2018).

Two patents: technological innovation and sustainability

Compared to existing methods for the treatment of chicken manure, CHIMERA represents a novelty for several reasons. The main solutions currently available for the combustion of chicken manure concern the technologies of the “moving grate” and the “fluidized bed”, but both types of solutions are generally economically sustainable for rather large farms, due to multi-step post-treatments (e.g. multi-cyclone, bag filters, DeNOx, scrubber) necessary to ensure off-gases compliance with emission limits.

From the study of patents relating to technologies already on the market, pyrolysis and gasification plants do not seem suitable for smell/medium-sized farms due to high temperature processes that require strong catalysis and costly management of animal by-products, with the transport of the chicken manure from the company to the plant and the movement of the ashes from the plant for disposal.

No pre-treatment of chicken manure transformed into a small plant

The CHIMERA technology uses a system small enough to be installed directly in the farm (dimensions: 15×9×6 m) or used in agricultural districts for both broilers and, in particular, for laying hens. Furthermore, the chicken manure is used “as is”, without pre-treatment (no drying and no homogenization). The air is injected in excess of oxygen, supplying the necessary heat to the gasification and pyrolysis areas; moreover, the combustion works at relatively low temperatures (around 800 °C), limiting the formation of nitrogen oxides and avoiding the use of specific equipment for their abatement (De-NOx) with a reduction in maintenance activities and costs. The ashes generated by the combustion process are introduced into the flue gas treatment circuit and the final product obtained is rich in nitrogen as well as phosphorus and potassium, which is not dispersed as happens in traditional plants.

Analysis of smoke management: the role of UNICAM (University of Camerino, Italy)

For the chemical analysis aimed at studying the use of manure as a fuel inside the plant, 3P Engineering has collaborated with the academic team led by Full Professor Enrico Marcantoni of the UNICAM University of Camerino (School of Science and Technology – Chemical Division). The analysis focused on the substance that is produced at the end of the combustion of the chicken manure, through the burner, which carries out a diffusive combustion of the biomass. The technological innovation relating to the burner concerns the biomass charge (flame-free) in the combustion air injection area. At the end of the combustion, the ashes and the by-product of the fumes pass through two serial scrubbers and turn into sludge. Subsequently, the sludge passes through a centrifugal decanter which separates the liquid part from the solid one, which is the final product. This is a inorganic fertilizer rich in nitrogen, phosphorus and potassium that can be used for spreading on land for the production of corn and wheat. A possibility that appears very important in this historical period, considering that last March the prices of soft wheat and corn marked a historical record in some countries, like in Italy, reaching 400€ per ton. Thanks to UNICAM, ammonia abatement and tar removal possibilities were evaluated, starting from the analysis of various techniques already known in the literature and which include biological, physical and chemical methods. Most of the known approaches, however, are rather expensive and require a high degree of maintenance, while from the analysis conducted by the team of the University of Camerino, the biomass dry filter appears as a cheaper and above all ecological option. In particular, the tar removal efficiency of bio-based filters increases in the presence of scrubbers, as in the case of CHIMERA technology, validating the engineering choices for the realization of the plants.

Pilot plant ready for the Netherlands

To test the technology in different situations, two plants have already been installed in different kinds of poultry farms (including Fileni), on both broilers and laying hens farms. The chicken manure has shown very different behaviors in the two cases as regards the production times (in the breeding of broilers, the chicken manure is produced in cycles of 2-3 months, while in laying hens, the chicken manure is in a continuous cycle). Some differences also in chemical compositions, in terms of density and humidity, partly due to the feed and the type of bedding used (with or without straw). New tests are in progress for market entry: the LIFE project is in the last phase of development and the pilot plant will be operational from June 2022 in the Netherlands, in Noord-Brabant, where it is based the Dutch farm Renders & Renders VOF, partner of 3P Engineering in CHIMERA. The study for the optimization of the fertilizer is being examined, together with the activities to evaluate the socio-economic impact of the new technology which, through the elimination of storage costs and the enhancement of chicken manure “on site” and “as it is”, proposes a turning point in terms of sustainability and profitability for the poultry farms.

“LIFE CHIMERA – CHIckens Manure Exploitation and RevAluation” is a Project funded by the European Union – GA n. LIFE15 ENV/IT/000631. The present document reflects only the author’s view. The Executive Agency/ Commission for Small and Medium-sized Enterprises is not liable for any use that may be made of the information contained.