Quality of eggs has a significant impact on hatchability and chick quality. Since a hatchery manager’s main aim is to produce the highest possible number of first- quality chicks, the evaluation of hatching egg quality should be an essential part of the standardised procedures in modern hatcheries.

Quality factors for eggs can be divided into two general groups: exterior and interior. This article presents an overview of the main exterior quality factors.

Exterior quality factors for hatching eggs

Good egg quality is a prerequisite for the production of healthy day-old chicks. It is therefore important to have a quality control procedure in place to evaluate the quality of incoming hatching eggs. Carefully checking the exterior qualifications of the eggs prior to incubation is strongly recommended. It can be helpful to break down the quality control process into steps and focus on the following factors: egg shape and size, eggshell quality, eggshell cleanliness and egg colour.

1. Egg shape and size

The first thing to look at when evaluating incoming eggs is their shape and size. A good-quality hatching egg has an oval shape with a large end (air cell end) and a clearly recognisable sharp end. The egg receives its particular shape because it is pushed through the oviduct. It is also free of deformities. The shape index of a hatching egg is defined as the ratio of the width to the length of the egg. As an example, an egg with a width of 4.2 cm and a length of 5.7 cm has a shape index of 74, which is considered to be within the optimal shape index range of 72-76.

Shape index = (width divided by length) x 100:

– Shape index below 72: egg is too long.

– Shape index above 76: egg is too round.

– Shape index ranging from 72 to 76: optimum.

In case of an increase in the number of misshapen eggs, it is recommended to immediately report this to the source farm so they can investigate the possible cause, such as disease, unbalanced feed, poor environmental conditions or stress. It means the eggs’ quality has been compromised early on by the way they were laid, resulting in a lower hatchability.

Body-checked eggs differ from normal egg shapes: They are too small or too large, round instead of oval.

2. Eggshell quality

2. Eggshell quality

The eggshell has an essential function in providing a sealed, protected environment for the embryo to grow in while allowing the transfer of gases and water, which are vital to the embryo’s development. Therefore, it is important that the eggshell is strong and intact. Eggs with the following deficiencies should never be incubated:

- Thin shell.

- Shell with calcium deposit (white, irregularly shaped spots deposited on the shell).

- Wrinkled shell.

- Mottled shell (translucent areas).

- Cracked shell (hairline cracks or any other type of cracks).

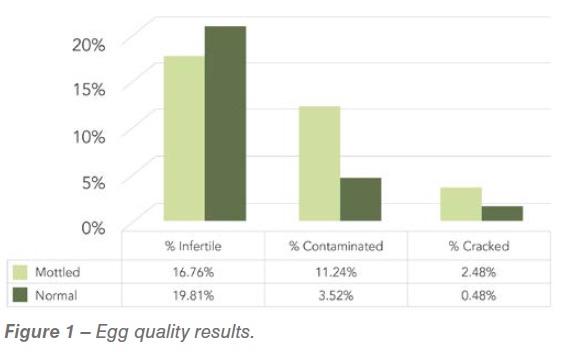

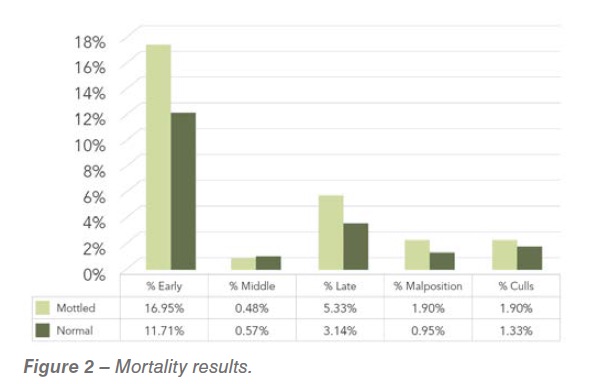

Mottled shells, for instance, make it easier for bacteria to enter the egg and affect hatchability. To quantify the negative effect of this deficiency, Petersime has run a trial. In a given hatchery, about 12.6% of all incoming eggs had a mottled shell. 1,050 of the affected eggs were incubated alongside normal eggs from the same flock. The trial results showed that eggs with mottled shells give proof of:

Mottled shells, for instance, make it easier for bacteria to enter the egg and affect hatchability. To quantify the negative effect of this deficiency, Petersime has run a trial. In a given hatchery, about 12.6% of all incoming eggs had a mottled shell. 1,050 of the affected eggs were incubated alongside normal eggs from the same flock. The trial results showed that eggs with mottled shells give proof of:

- Increased contamination (see Figure 1).

- More cracks (see Figure 1).

- Higher mortality across all stages of incubation as well as more culls (see Figure 2).

Abnormal shells may result from improper nutrition (lack of calcium, phosphorus, vitamin D), disease or the poor physical condition of the hen. Shell thickness is also influenced by flock age: As a hen ages, her eggs become larger, which means the proportion of calcium per egg lowers, causing the eggshell to be thinner.

Abnormal shells may result from improper nutrition (lack of calcium, phosphorus, vitamin D), disease or the poor physical condition of the hen. Shell thickness is also influenced by flock age: As a hen ages, her eggs become larger, which means the proportion of calcium per egg lowers, causing the eggshell to be thinner.

The most common test for shell thickness is a specific gravity test that uses the salt bath method.

Several salt baths of varying specific gravity – salt concentrations ranging from 1.060 to 1.090 in increments of 0.005 – are prepared. The specific gravity of the solution in which an egg floats is the specific gravity of the egg. The eggs are first placed in the tub with the lowest salt concentration. The specific gravity estimate is recorded for those eggs that float. The eggs that sink are removed and placed into the next tub until all eggs have been recorded to float.

Past trials have revealed that eggs with specific gravity values between 1.070 and 1.085 indicate a good shell quality and generally give better hatchability results. During those trials, specific gravity also proved to be a more determining factor in reaching high hatchability rates than egg weight loss during incubation. In other words, good eggshell quality is critical for successful incubation and hatching.

3. Eggshell cleanliness

It is important to keep only clean eggs for hatching. A dirty egg can be a sign of contamination and should never be incubated:

A shell that has dirt or foreign material adhering to its surface.

A blood-stained shell.

Moreover, an egg that appears ’clean’ can still have a certain count of bacteria covering its shell. Using ultraviolet light will reveal the true condition of the eggshell.

4. Egg colour

4. Egg colour

Although egg colour is a specific trait of the breed and influenced by the feed the hen receives, it can still tell something about the quality of hatching eggs. In general, it is important that the egg colour is uniform within a batch. When talking about brown eggs specifically, it is well-known that older flocks lay paler eggs compared to younger flocks, but an increase in the number of pale eggs in a batch of incoming eggs can also indicate that the flock is suffering from disease or stress, affecting shell pigmentation during egg formation. Apart from these points, the impact of egg colour on egg quality is considered to be small.

In conclusion

Do not take egg quality for granted. It is necessary to evaluate external egg quality on a routine basis and take action to achieve the required improvements. The type of information gathered during quality control should be used as a feedback mechanism to the breeder farm for performance improvement, or as an early detection of possible issues that may have a bigger impact later in the hatching process.