Once the market-age birds arrive the plant the personnel must concentrate on the preservation of their physical integrity and economic potential. In such scenario, the hanging area plays a vital role for the successful accomplishment of this endeavor given it is responsible for handling the so-sensitive live broilers.

“Failure is the seed of success”. Kaoru Ishikawa (1915-1989)

Eng. Fabio G. Nunes – Poultry Processing Consultant, Brazil

fabio.g.nunes@hotmail.com

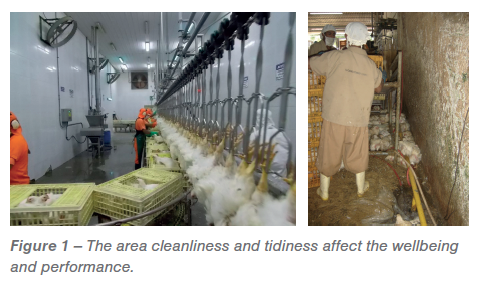

In the daily struggle to safeguard the integrity of the raw material, the hanging team is the top priority, as its wellbeing influences their performance and ultimately the processing outcome, as well. Therefore, it is expected that a workplace that ranks cleanliness, proper illumination, work ergonomics, air quality, and personal safety as priorities, and founds the interpersonal relationships on respect, recognition, and gratitude, is very likely to influencing positively the team’s mood and performance. In short, care the workers and they’ll care the broilers (Figure 1).

Broilers are hauled from farm to plant either into plastic crates or containers. Plastic crates and drawer containers protect birds’ integrity till they are suspended to be hung. Oppositely, for cascading hundreds of birds from a few feet high onto a conveyor belt, the dump container has long proven to be injurious to the carcasses. Authors indicate the method injuries 1% of the wings with 74% of it from female birds. Keep transport units always in good physical conditions and set aside the damaged ones.

When suspending birds to hang do it gently and always by the legs; grip the shanks, not the legs, between the index and middle fingers upon shackling (Figure 2).

Shackles should never be damaged or missing, as it leads to the line and hanging speeds; gauge them periodically to match the average bird’s weight, thus allowing the feet to settle effortlessly and uniformly at the bottom of the shackles, thus preventing the birds from paining and hocks from damaging, while contributing to the stunning, scalding, picking and hock cutting consistency and efficacy.

The hanging station-stunner line track must be ideally free of ascents, descents, and curves which incites agitation and wing-flapping on birds. A smooth-surfaced breast comforter to calm birds down while heading to the stunner prevents wing flapping and secures their uniform, limp posture prior to stunning.

Broilers must be stunned prior to slaughter for operational safety, quality, and animal welfare concerns. Halal and Kosher slaughter are the only exceptions. The electric stunner still is the commonest method used by the poultry industry despite the availability of other technologies. The dynamic interference of countless variables in the process makes it hard to set, though. Yet no universal rule governs the electric stunning practices, being a requirement of each country, the concern about its effects on the carcass is universal, though!

Securing injuries-free stunning requires taking some cares into consideration: maintain the stunner and the electric circuit always in good conditions; guarantee accuracy of dashboard instruments; wet feet-shackle intersection for enhanced conductivity; keep tub water level stable; guarantee shackles-guide bar (earth pole) uninterrupted contact along the tub; 7 to 10 seconds is the optimal birds dwelling time into the tub; the grid’s (pole) and tub’s dimensions must match; adjust stunner height to the flocks in process; eliminate pre-stunning at the entrance and check post-stunning behavior at the exit.

Properly stunned birds have their necks severed either manually or automatically no further than 15 seconds from stunning to avoid regain of consciousness that leads to wing flapping. Neck cut must severe the vessels and keep trachea and spinal cord untouched to prevent premature death and poor exsanguination, while allowing for a smooth scalding and plucking. Employ only skilled operators and keep knives sharpest for manual bleeding. Bleeding time no longer than 150 seconds, or even shorter, guarantee low rigor mortis birds entering the scalder and a further smooth scalding and a low-impact, damage-free defeathering. Secure no birds enter the scalding tank alive.

The hanging area embraces just a handful of operations. However, its responsibility towards the live raw material is enormous, given any damage resulting from its poor handling will perpetuate all way down the processing line, affecting not just the quality of the carcass, but the company’s bottom line, as well.

Literature available from the author upon request.