Between December 2014 and June 2015, 223 outbreaks of the highly pathogenic Avian Influenza (AI) virus in commercial and backyard flocks occurred in 15 states of the USA. It was the most severe epizootic event in the history of the poultry industry in this country. According to preliminary estimates, the monetary impacts reached a volume of 2.6 billion US-$, and almost 15,700 jobs were lost. It will take up to two years for this sector of animal production to recover from this blow, especially in the states which were mainly affected.

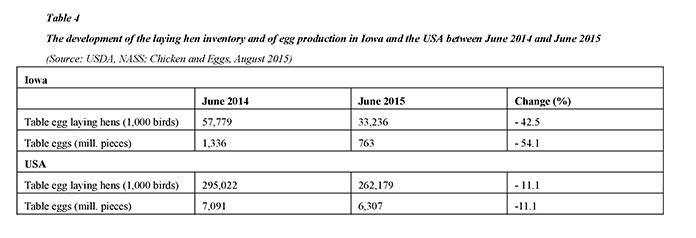

Iowa, the leading state in egg production, lost 42.5 % of its table egg laying hen inventory between April and June 2015; table egg production even decreased by 54.1 %. Although the outbreaks in turkey farms were less dramatic than in Minnesota, the loss of 1.4 million meat turkeys also hit a considerable number of small and medium-sized farms severely[1].

The role of the poultry industry in Iowa’s agriculture

In 2014, Iowa ranked in an unchallenged leading position in egg and pig production of the USA, sharing 19.6 % in the laying hen inventory and 30.9 in the pig inventory. Because of the AI outbreaks, the contribution to the laying hen inventory decreased to 12.7 %.

Despite Iowa’s leading position in laying hen husbandry and egg production, the contribution of the poultry industry to the total production value of agriculture reached only 4.2 %. Nevertheless, the economic impact of the egg industry must not be underestimated as it is an important customer for the corn and soybean producing farms and also creates several thousand jobs on the egg farms and in the egg processing industry. The AI outbreaks not only reduced the value of egg production considerably, but also led to a high loss of jobs and to a remarkable reduction of the purchased corn and soybeans.

The time-spatial dissemination of the AI outbreaks

The first infections of poultry flocks by the highly pathogenic avian influenza virus were detected in December 2014 and in January and February 2015 in backyard and commercial flocks in Oregon, Washington, Idaho and California. As the number of outbreaks was small, the situation did not seem alarming. The first outbreaks outside the Pacific region were documented between March 3rd and 28th in Arkansas, Kansas and Missouri. But still the number of cases was small. The situation changed considerably when in April 16 new outbreaks were detected in Minnesota and the Dakotas, mainly in turkey farms. In the following weeks, the number of infected farms increased dramatically and reached 87 outbreaks between April 21st and May 5th (see Windhorst, 2015).

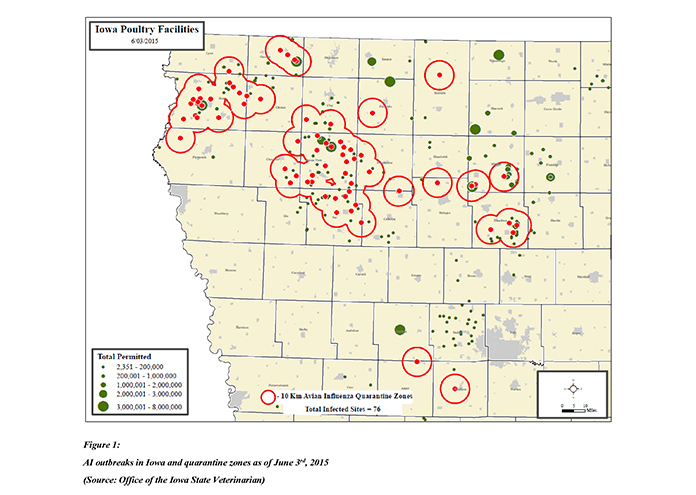

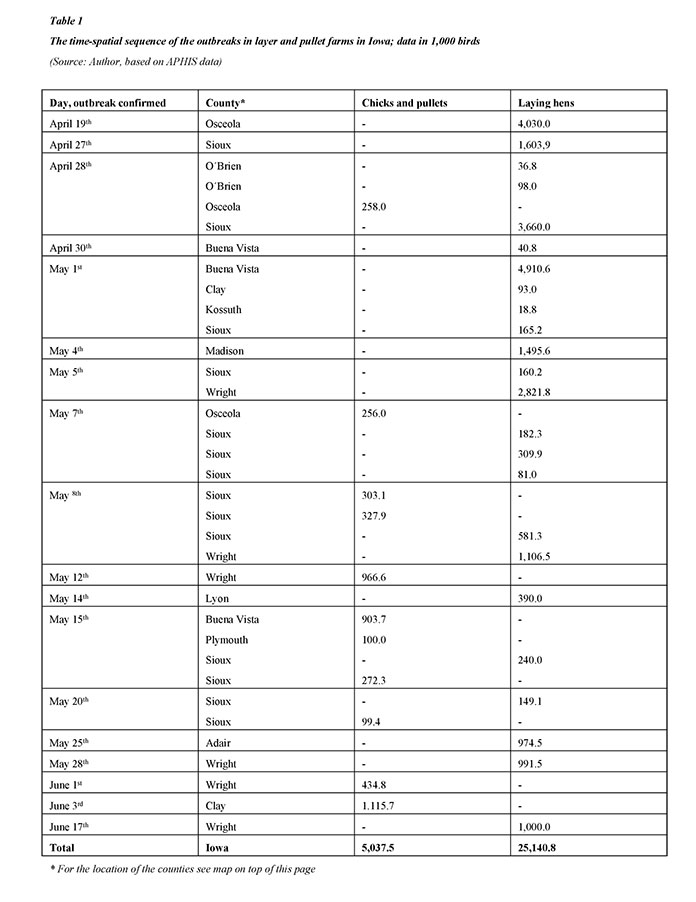

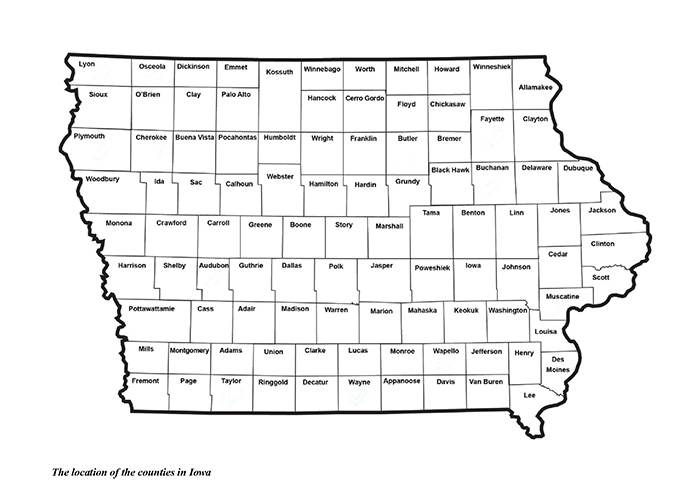

The first outbreak in Iowa was confirmed by the Animal and Plant Health Inspection Service (APHIS), an office of the United States Department of Agriculture (USDA), on April 19th in a  large table egg layer farm (4 million birds) in Osceola County. In the following two months, 64 more outbreaks were confirmed, mainly in layer and pullet farms, but also in turkey farms. The outbreaks were concentrated in the northwestern part of the state (Table 1, Figure 1) with centers in Sioux, Buena Vista and Sac counties. All infections were caused by the H5N2 strain which is a combination of the low-pathogenic North American viruses and the highly pathogenic Asian strains. Although the H5N2 virus is highly pathogenic to commercial poultry, it does not kill the waterfowl from which the virus was transmitted to the turkey flocks. While the first infections in turkey farms obviously came from infected wild birds, the clusters of infected farms made it likely that the virus was transferred either by persons, by feed trucks or equipment which was used by various farmers.

large table egg layer farm (4 million birds) in Osceola County. In the following two months, 64 more outbreaks were confirmed, mainly in layer and pullet farms, but also in turkey farms. The outbreaks were concentrated in the northwestern part of the state (Table 1, Figure 1) with centers in Sioux, Buena Vista and Sac counties. All infections were caused by the H5N2 strain which is a combination of the low-pathogenic North American viruses and the highly pathogenic Asian strains. Although the H5N2 virus is highly pathogenic to commercial poultry, it does not kill the waterfowl from which the virus was transmitted to the turkey flocks. While the first infections in turkey farms obviously came from infected wild birds, the clusters of infected farms made it likely that the virus was transferred either by persons, by feed trucks or equipment which was used by various farmers.

A closer analysis of the sequence of the outbreaks reveals that about one week passed after the first farm was infected on April 19th before a second outbreak was detected in Sioux County which would soon be the county with the highest number of cases together with Buena Vista County. From Sioux County it spread to Buena Vista, Clay and Kossuth Counties before new outbreaks affected several more layer and pullet farms in Sioux County. After an infection of a pullet farm was confirmed in Clay County on June 3rd, a pause of about two weeks gave hope to the assumption that the dissemination of the virus had come to an end. But then, a new case was confirmed in a layer farm with 1 million birds on June 17th in Wright county. After that, no new infections occurred. The data also shows that of the 35 outbreaks 11 occurred in pullet and 24 in layer farms. Nine of the affected farms had more than 1 million birds; they shared 81.2 % of the total number of infected respectively killed pullets and laying hens.

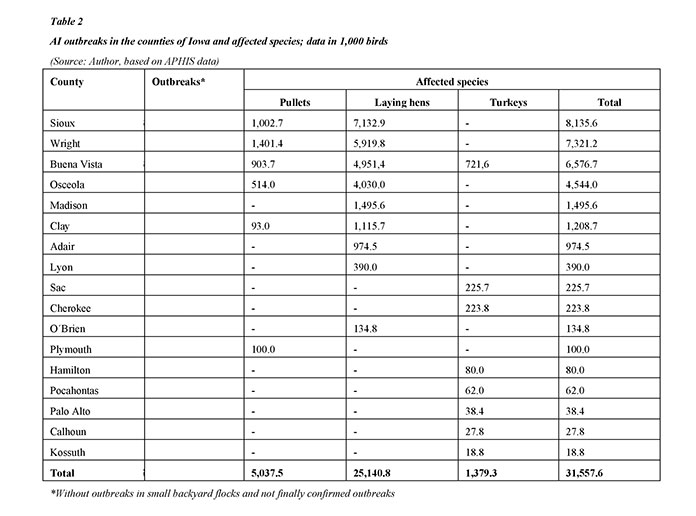

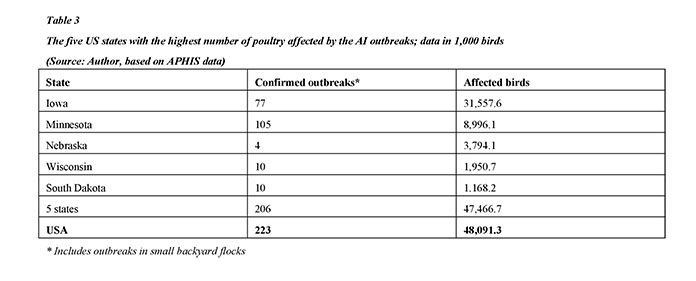

Table 2 lists the counties according to the number of infected birds by species. One can easily see that 38 outbreaks occurred in only four counties (Sioux, Buena Vista, Wright and Sac) and that in three counties (Sioux, Wright and Buena Vista) 22.0 million birds fell victim to the AI virus. The data in Table 3 shows that Iowa with 31.6 million birds shared 65.6 % in the total loss of chickens and turkeys, followed by Minnesota with 9.0 million birds (18.7 %) and Nebraska with 3.8 million birds (7.9 %). So it is not surprising that not only the most severe problems in the depopulation and deposition of the carcasses showed up in Iowa but also that this state was confronted with massive economic impacts.

The data in Table 3 shows that Iowa with 31.6 million birds shared 65.6 % in the total loss of chickens and turkeys, followed by Minnesota with 9.0 million birds (18.7 %) and Nebraska with 3.8 million birds (7.9 %). So it is not surprising that not only the most severe problems in the depopulation and deposition of the carcasses showed up in Iowa but also that this state was confronted with massive economic impacts.

Depopulation and deposition problem

As most of the infected turkey flocks in Minnesota and also later in Iowa and other states were much smaller than the affected laying hen flocks, the euthanisation and depopulation of the birds did not cause serious problems. The turkeys were killed by a water-based foam and then composted within the barn. When, however, the large layer farms with several million birds were infected, the situation changed completely. High-rise barns with up to 12 tiers were a challenge. It would have been possible to kill several hundred thousands of birds with CO2 gas within a short time, but as it was not possible to depopulate the barns within a few days, serious hygiene-problems would have occurred. So it was decided by the Animal Industry Bureau of the Department of Agriculture and Land Stewardship that so-called mobile modified atmosphere killing carts (MAK) using CO2 would be used instead of euthanizing the whole flock in a barn. One MAK could handle up to 100,000 birds per days. Even when using several carts at one location, the depopulation of one of the huge complexes would need up to two weeks or even more. The situation escalated when within a few days several large farms were affected (see Table 1). In the meantime the virus further spread and the high mortality rate also caused hygiene-problems. Because the ventilation system was not shut down, the outgoing air contained virus material which may have spread over longer distances ad caused new outbreaks.

As the carcasses could not be composted inside the layer barns, other ways of getting rid of them had to be found. The carcasses were stored in sealed bio-bags and then transported with special trucks to landfills which had agreed to deposit them. Some of the landfills were up to 200 km away from the infected farms, a risk of the further dissemination of the virus if either the bags or the trucks would leak. A small amount of the carcasses was either buried close to the barns or incinerated.

It was not before early August that that all farms were depopulated and the carcasses deposited. If this method will again be possible in case of another massive outbreak is an open question as some of the landfill owners already announced that they would not accept poultry carcasses in future.

Impacts of the AI outbreaks on Iowa’s egg industry

The AI outbreaks had not only far reaching impacts on Iowa’s egg industry and the state’s economy in general but also on egg production of the USA.

The loss of 26 million layers and over 5 million pullets resulted in a dramatic decrease of the laying hen inventory and of egg production. Table 4 shows that Iowa’s laying hen inventory was 42.5 % lower in June 2015 than in June 2014 and that table egg production even decreased by 54.1 %. The share of the Iowa laying hen inventory in the overall inventory of the USA fell from 19.6 % to 12.7 % in the same time period. The USA table egg layer flock fell from 295.0 million birds to 262.2 million birds or by 11.1 % and table egg production from 7.1 billion to 6.3 billion pieces.

Decision Innovation Solutions, a consulting firm located in Urbandale (Iowa), was asked by the Iowa Farm Bureau to calculate the cost of the AI outbreaks between April and June 2015. The firm estimated the total cost to the economy of Iowa at $ 1.2 billion. This includes $ 800 million as direct losses in egg and turkey production and $ 400 million for wages and taxes. The firm also estimated that Iowa might lose about 8,500 jobs as a result of the 77 outbreaks (Decision Innovation Solutions, 2015a, p. 13). For the USA the company estimated an output loss of $ 2.6 billion and a loss of 15,693 jobs (Decision Innovation Solutions 2015b, p. 3).

About 85 % of the infected and depopulated table egg laying hens was producing eggs for the egg processing industry, mainly in large inline operations (see Figure 2). This resulted in severe economic problems for the leading companies. They were no longer able to fulfill their contracts with the food industry. One company declared force majeure hoping that this might be accepted by the food industry. The industry, however, argued that there were still sufficient eggs for further processing available on the domestic and the global market. Obviously, some egg processors began to purchase shell eggs for consumption for their processing plants, not only in the USA but also on the international market. This initiated a dramatic increase of the retail price for shell eggs in the USA.

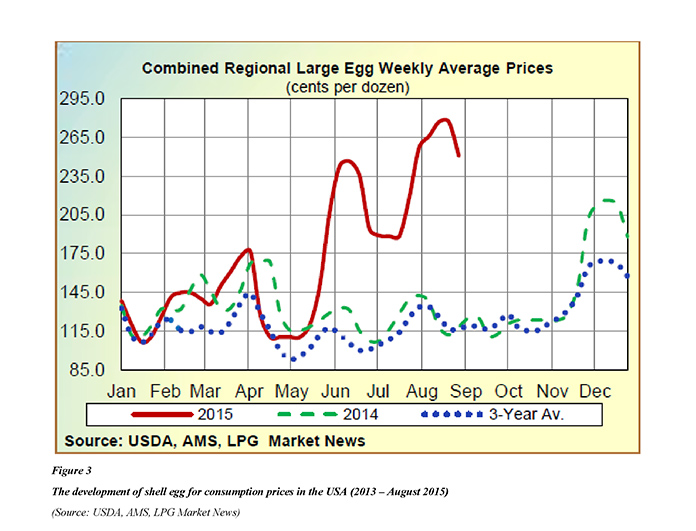

In the first week of June, between $2.24 to $2.42 US dollar had to be paid for a dozen of large eggs, 60 % more than in the preceding week, but towards the end of June, prices decreased to $1.90 per dozen again (see also Figure 3) and remained fairly stable until mid-July. But then prices increased again because of the considerable reduction of the laying hen flocks and the constant demand for table eggs and eggs for further processing. In California, more than $ 3 had to be paid for a dozen of large eggs according to a report of the Egg Industry Center (Iowa State University, Ames). Because of the high retail prices, consumers bought less table egg which resulted in lower egg prices in late August and early September.

The loss of 11.1 % of the average table egg layer inventory resulted in a shortage of egg products, in particular liquid egg products for the food industry. To reduce the shortage and to stop the rapid price increase (almost $ 10 per pound for dried whole egg powder and $ 2.10 per pound for liquid whole eggs) the food industry applied for an opening of the US market for foreign egg products. The Trade Department gave permission to four egg processing companies in the Netherlands to export to the USA. They already had a permission to export to the USA, but had not delivered products since 2012.

The AI outbreaks caused a loss of $ 390 million in export value in the first half of 2015 compared to 2014 according to a report of the USDA Poultry & Egg Export Council. Even though mainly turkey and laying hen farms were affected, the AI outbreaks also impacted the broiler industry. The National Chicken Council estimated in a press release that the export volume in 2015 would be about 9 % lower than in 2014. On the other hand, Brazil could profit from the situation. Several countries, which imported leg quarters from the USA, were looking for alternative sources of supply. CEPEA Brazil (Centro de Estudos Avançados EM Economia Aplicada) announced that they were expecting the highest export volume for July 2015 with more than 400,000 t.

The banning of imports from the USA has already had and still has impacts on the breeding companies in the USA as they could not export breeding stock, hatching eggs or one-day-old chickens to several countries as long as the quarantine zones were effective. This led to a considerable interruption in the export of parent stock to countries outside the USA. The situation became even more serious for Hy-Line (Dallas Center, Iowa), the leading breeding company for laying hens, when an AI outbreak occurred in the United Kingdom in July which further reduced the export possibilities. It is estimated that it will take at least six months, perhaps even longer, to stabilise the international markets and trade flows. This will happen, however, only under the condition that no new AI outbreaks occur in the fall of 2015 or the spring of 2016.

Repopulation of affected farms

Before the affected layer farms can be restocked, several steps of cleaning, disinfection and testing have to be taken, as the State Veterinarian of Iowa, Dr. David Schmitt, explained to the Author during a meeting in Des Moines. After cleaning and disinfection, the barns are heated up for at least three days to a temperature of 100 °F (= 37.8 °C), this phase is called the “baking phase”. After that, a sanitary phase of 21 days has to follow. Then numerous samples are taken in the farms. If the results of the PCR tests are negative, the restocking can begin. If the tests are positive, additional analyses have to be undertaken to identify the virus status and to decide if the virus material is still virulent. If this is the case, the whole procedure has to be repeated. Before restocking the farms, the one-day-old chicks are tested and then again after 21 days and then three times in seven days intervals. It is assumed that these tests are sufficient to detect an infection in an early stage even though only 5 birds per flock are tested.

In contrast to the restocking of turkey barns which can be repopulated completely in one step because of the several growing cycles per year, the repopulation of the huge layer farms can only be done in several steps. This is necessary to have a flock of different ages and a constant egg flow. It is estimated that it will take at least 12 and perhaps even 18 months until the former production level will be reached again. The time needed to restock the farms will also depend on the availability of hatching eggs and one-day-old chickens. At the fall conference of the International Egg Commission in Berlin (September 20th to 24th) representatives of large layer farms declared that restocking of the farms would not begin before the end of October or early November.

Perspectives

The future development of the egg industry in Iowa will to a high degree depend on the ability to prevent a new wave of AI outbreaks in fall of 2015 and spring of 2016.

One challenge is the biosecurity problem on farm level. It is obvious that many poultry farmers in Iowa were not prepared for such an event. The biosecurity on farm level was not sufficient to handle the massive infection pressure (USDA, APHIS 2015). That is why state and federal agencies are developing programmes, workshops and online brochures for the farmers to improve the biosecurity of their farms. The rapid dissemination of the AI virus in some counties in Iowa has shown that the farmers were not aware of their deficits and not informed about the risks connected with personal contacts, the use of equipment by several farms and the risk of the introduction of the highly pathogenic virus by trucks which delivered the feed.

The dimension of the outbreaks and the resulting economic impacts raised the question if in addition to the stamping out of the infected flocks vaccination of the not infected herds should be permitted in case of a new wave of infections. While some of the egg farmers voted in favour of vaccination, many veterinarians and egg products as well as broiler meat exporting companies opposed such a step because of the foreseeable impacts on the exports of poultry products. Even though the USDA asked vaccine-producing companies to stockpile large amounts of vaccines against the H5 virus strain, it is a still open question if it will be used in a situation when all other means to stop the disseminarion of the virus are not sufficient.Another topic which was discussed severely in September 2015 was the shutdown of the ventilation system in a large affected layer farm in case of an outbreak of the HPAI to meet the demand of the USDA to kill the laying hens within 24 hours to prevent a further dissemination of the virus. Tests carried out by Prof. Hongwei Xin (Iowa State University, Ames) showed that this can kill even large flocks within 20 minutes to several hours because of the heat stress as the temperature inside the barn can increases to 122 °F (=50°C). The USDA, however, made clear in a directive (USDA 2015) that a ventilation shutdown can only be applied if no other method is be able to kill a flock within 24 to 48 hours. Even though the USDA has basically agreed to the application of such a method, several ethic problems remain and will definitely be discussed in the US society.

[1] This article is based on intensive field studies in July and August 2015 in the northern Midwest of the USA, interviews with state veterinarians, scientists and leading persons from the poultry industry.